HP and the Space Conquest

To mark the fortieth anniversary of the first man's stepping on the moon, here is a review of some articles published by the Hewlett Packard Company during that remarkable period of the space conquest. They all reflect the many contributions made by the HP products for the success of this great accomplishment.

|

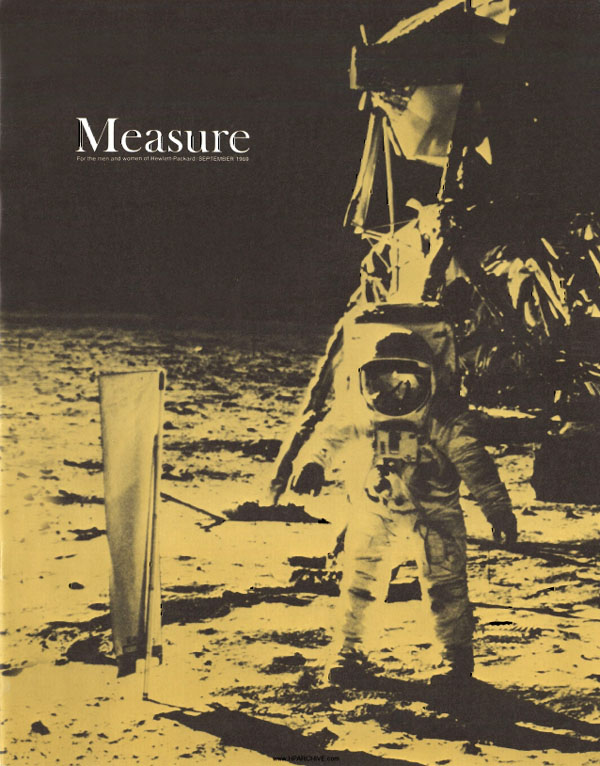

Cover of the first issue of MEASURE Magazine - July 1963

Courtesy of Hewlett-Packard Company

|

A SANBORN "350" HELPS MAKE SPACE HISTORY

HP products' contribution to the space conquest began very early with the Project Mercury space effort, as shown on the cover of the first issue of MEASURE magazine which was published July 1, 1963.

"WHEN GORDON COOPER finally got home to the wife and kids after his 590,000-mile trip, he probably held the distinction of being the most weighed, measured, poked-at, and looked-into man on earth. A crack team of physicians and medical technicians wouldn't let him out of "sight" for a moment. The fact that they could check and record his temperature and heart beat, and practically give him a complete physical while he was in orbit at 17,500 miles an hour, is one of the more remarkable aspects of the flight. A wonderfully complicated and sophisticated array of electronic equipment made it possible.

Among that equipment was a Sanborn "350" 8-channel recording system. The cover photo shows Cooper suited-up in Hangar S at Cape Canaveral and in the background a technician is seen operating the recorder. For several hours prior to the May 15 flight, information was gathered on a multitude of his body functions. A check was made of his temperature at several points on his body, and respiration, pulse, heart rate, and blood pressure norms were determined so that all changes occurring in orbit could be recorded.

Instruments such as the Sanborn "350" provided permanent visual records of all these data for future study by experts in the field of space medicine. The vital nature of such information cannot be overemphasized. The success of future space flights and the safety of the heroic astronauts may depend on its quantity and its accuracy."

HP and the Apollo Program

|

| MEASURE Magazine May 1969 - Courtesy of the Hewlett Packard Company |

|

From MEASURE Magazine May 1969

Courtesy of the Hewlett Packard Company

|

HP to The Moon

MEASURE Magazine May 1969

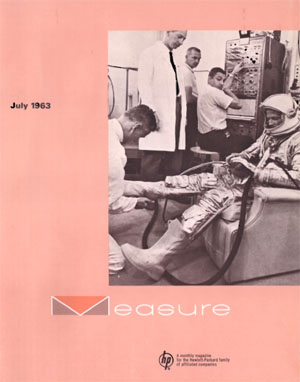

If all goes well with the Apollo project, a number of Hewlett-Packard products will land on the moon this summer. Others will be aboard the command module and have a vital role in communicating with the moon landing vessel and - in one instance - guiding it back to an orbital rendezvous. All of the products are solid-state devices. Included are high-power PIN diodes and microwave detector hot-carrier diodes from HPA Division, and solid-state switches now produced by the Microwave Division's component section.

The diodes for the most part are involved in the Unified S-band communications system and serve a variety of functions. The switches, on the other hand, have a key role in the rendezvous guidance antenna system. Actually only one 3530 switch would be needed for this function, but eight of them have been installed to reduce any possible risk virtually to zero. All of the items shown (typical of those at right) are shelf-type products, but very rigorous environmental testing was performed by HP to insure the highest possible quality and safety rating.

|

Bill Hewlett "From the President's Desk"

MEASURE Magazine September 1969

Courtesy of the Hewlett Packard Company

|

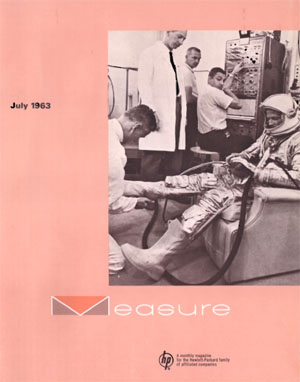

From the President's Desk

MEASURE Magazine September 1969

Certainly one of the great accomplishments of our time was the landing of astronauts Aldrin and Armstrong on the surface of the moon. It was a thrilling experience for the millions of people who followed the flight of Apollo 11. To think that man was actually walking on the moon was incredible enough; to have this feat televised and sent back a quarter of a million miles through space was for me the capstone. Admittedly, this one aspect was only a small part of the Apollo program, but it involves a technology that I understand and appreciate. And it emphasized to me the fantastic scientific contributions that are making the space program possible. It was an absolutely astounding demonstration of our technology.

In another part of this issue of MEASURE, editor Gordon Brown has written an article that discusses the part Hewlett-Packard played in the Apollo program. One group of our instruments mentioned in the article, the cesium beam frequency and time standards, were of critical importance to the successful navigation of the Apollo vehicles. It is interesting to note that these instruments meet our standard HP commercial specifications and yet were good enough to be selected by NASA for this critical role. This is a very great tribute to the commercial quality of our products.

It is exactly this kind of quality on which the company has built its reputation. Quality, however, is a perishable commodity, and unfortunately an incident of poor reliability in any one of our product areas can tarnish the entire corporate image. Quality is not a new subject for discussion. The problem is always with us, and can be overcome only by all of us recognizing the extreme importance of having "quality" associated with all HP products.

I think this whole subject takes on increasing importance as we move from the era of relatively simple instruments, used by themselves, toward the more sophisticated grouping of instruments. A good example is the network analyzer, which basically is an assemblage of standard HP equipment. Such system grouping of instruments compounds our reliability problem, for if one instrument in the system fails then, in many cases, the total system is out of service.

Not all customer applications of our equipment are as critical as those occurring in the Apollo program, but regardless of the application, the failure of any instrument or component has a serious effect on HP as a manufacturer of quality instrumentation. I cannot stress enough the importance of close attention by all of us to the maintenance of highest quality and reliability standards.

|

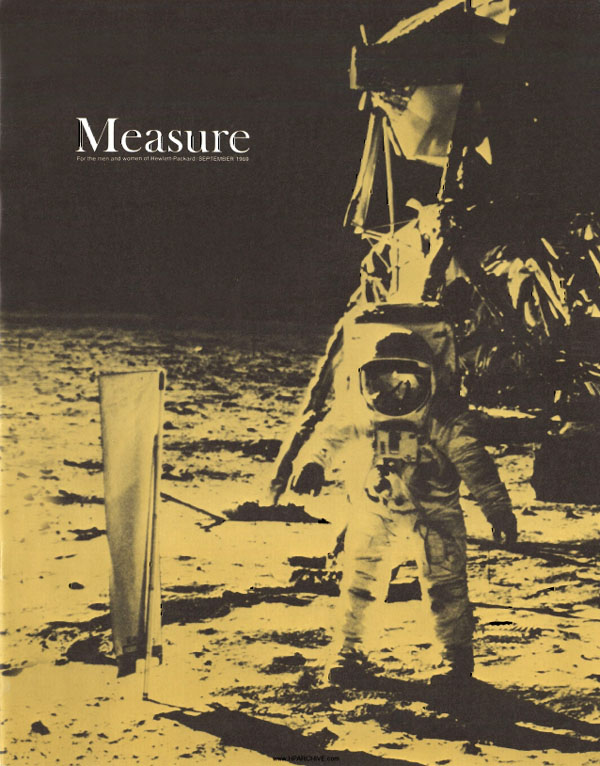

| Cover of MEASURE Magazine September 1969 - Courtesy of the Hewlett Packard Company |

The Giant Step

HP was there, with Armstrong and Aldrin, and during the many other steps that took man to the moon . . .

The Article from MEASURE Magazine discussed above by Bill Hewlett is reproduced below:

For a couple of magic hours last July, the world stood still long enough to watch the men on the moon walk and run and leap right into history. Only the finding of a bottled message adrift in the sands of the Sea of Tranquility could have provided more excitement and suspense than the landing and explorations by Armstrong and Aldrin, and finally their rendezvous with Mike Collins. No such cosmic mystery occurred, of course. Everything went precisely as programmed - like atomic clockwork.

As many people in the company know, HP cesium beam frequency standards were indeed the atomic clocks that kept the worldwide Apollo network of 18 tracking stations and communications systems synchronized to within a few thousandths of a second. In turn, the precise workings of the earthbound systems made an extremely important contribution to the navigational accuracy of the Apollo 11 spacecraft. At all times save when hidden from earth by the moon, its position was known to within a few feet. Had any navigational problems developed during any of the many critical maneuvers, particularly the docking and lunar departure phases, Houston Control would have known about it almost immediately and been able to analyze and direct corrective action.

However, as MEASURE found in checking with the various divisions and sales offices, Hewlett-Packard's involvement in the Apollo project goes well beyond precision frequency standards. It appears, in fact, that products of almost every division have been employed on behalf of the NASA space-flight programs.

As a prime example, Al Wilson, quality assurance manager of HP Associates, wrote the following at the very time Apollo 11 was heading back from the moon: "As you follow the progress of Apollo 11 on its historic flight to the moon, you can be proud of the fact that HPA has helped make it possible. Our Hot Carriers, PIN, Step Recovery Diodes and a PIN switch are there as they were in the other Apollo flights. Our diodes are also in the Eagle. After it landed on the moon, some of them were with Armstrong and Aldrin in their communication system during their walk on the moon."

Those HPA products were the subject of a commendation from one of the contractors responsible for the communications systems. Paul Leinheiser, purchasing manager of Motorola Inc.'s Government Electronics Division sent the following wire to general manager Dave Weindorf: "The Motorola S-band transponder and up-data link on the Apollo command module and the S-band transceiver on the lunar module performed flawlessly. These units provided the only voice and television link our astronauts had with earth after their spacecraft reached a point 30,000 miles from earth, and transmitted the first voice and TV pictures ever sent from the moon to earth.

"We at Motorola commend you and your dedicated employees who helped make this possible. Without your able support and constant attention to the reliability of your company's vital components required to produce this equipment we seriously doubt that the Apollo 11 mission would have been successful. Our sincere thanks, congratulations, and a hearty well done ..."

Well, not all HP applications could be so spectacularly or directly linked to the moon landing. Yet, in the buildup of the nation's space capability following Sputnik, every step was related to the next. As the captions to the accompanying photos show, HP products were vital in many of the most important steps that led finally to those first footsteps on the moon itself.

|

At one mile per hour, Saturn V Apollo moves along crawlerway to launch complex at Cape Kennedy. The three lower booster stages plus the instrument unit were developed at Marshall Space Flight Center, Huntsville, Alabama, with HP furnishing an extensive array of test equipment. For example, prior to joining the company, P. K. Weir and Siler Manley of the Huntsville office designed the very complex facility, employing HP data acquisition system, used for pressure testing of liquid oxygen tanks. Some other important Huntsville applications: Waltham recorders for data communications between Marshall and the Cape; HP scopes in launch support operations by the Computation Lab; data acquisition systems for monitoring accelerometers and strain gauges by the Propulsion and Vehicle Engineering Lab; data systems, signal generators and power meters in tne Astrionics Lab used in development of the Apollo guidance unit and the on-board RF system; and data systems and digital voltmeters at the Static Test Stand.

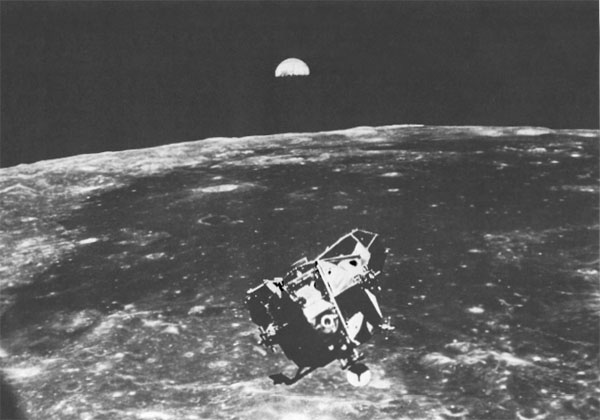

Here, on July 17, the ascent stage of Eagle approaches for its brief rendezvous with Columbia. Earth is seen above the lunar horizon. HPA diodes and switches on the lunar moduIe were very much in action during this critical docking maneuver as well as in astronaut communications during the moon walk. In addition, scores of HP instruments were employed in testing and calibrating the LM at Cape Kennedy prior to launch. In testing the various communications, guidance and tracking systems, Cape scientists used HP frequency synthesizers, signal generators, scopes, analog and digital recorders, and data acquisition systems. Transmissions from the spacecraft were recorded on a variety of HP recorders.

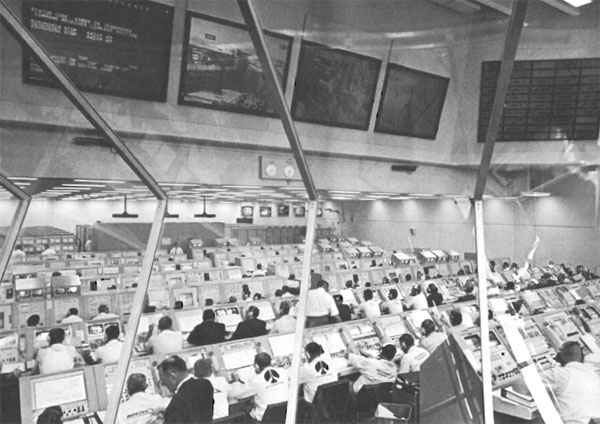

Launch Control Center at Cape Kennedy, shown here, and Mission Control Center at Houston both were equipped with a wide range of HP gear for communications systems and calibration facilities. The New Jersey Division, for example, provided precision picture monitors, power supplies, FM-AM telemetering signal generators and RF vector impedance meters.

|

Part of a 1976 HP's advertising poster showing

a NASA astronaut using an HP-65.

The world's first magnetic-card-storage, handheld calculator.

Photo Courtesy of Hewlett-Packard Company

|

After Apollo 11,

Another Decade of Space Conquest

Following the Apollo11 mission, the space conquest continued to be a considerable power booster for the American technology evolution during the 1970s.

The four latest Apollo missions: Apollo XIV, XV, XVI, and XVII continued and concluded the moon surface exploration between February 1971 and December 1972.

Skylab was launched in 1973, and Apollo-Suyuz, was the first international manned spaceflight in 1975.

Viking I and II landed on Mars in 1976.

Voyagers I and II headed into the solar system in 1977.

After its introduction in 1974, the HP65, world first fully programmable pocket calculator, became a standard tool for every crew of NASA astronauts.