One of our main objectives in starting this website five years ago was (and still is today) to get in touch with people who have worked at HP from the birth of the company up to today. We are interested in hearing your memories no matter what division or country you worked in, or whether you were in engineering, marketing, finance, administration, or worked in a factory. This is because all of you have contributed to the story of this unique and successful enterprise.

Your memories are a treasure for this website. While product and technology are our main concern, other writings related to the company life are highly welcome, as far as they stay inside the HP Way guidelines.

The contributions made by Edward H. Phillips during his career at HP are illustrated in this chapter. This chapter is a good example of the type of memories we would like to present on this website.

Many thanks Ed for this highly valuable contribution.

Anybody Else ? Please get in touch using the Contact US form.

My Time with hp, by Edward H. Phillips (1956 to 1966)

Table of Contents:

Actually, my family connection with Palo Alto goes back to 1907 when my maternal grandparents moved there with a newborn child (my mother). My grandfather had been an accountant back in Michigan and had briefly worked as a bookkeeper for Henry Ford when he occupied a rented building (i.e., such as you can see today at Greenfield Village in Dearborn). This was a long time before the Silicon Valley came to be of course, and confronted with a lack of any requirement for accountants my grandfather became a self-taught architect and contractor. This was because Mrs. Stanford was bringing in a number of professors from the East and they needed places to live. You can still see the old pre-WWI homes that he built along Embarcadero Road for a few blocks East of Alma Street. But a few years later, he ran out of newly minted Stanford professors and so the young family moved to the East Bay.

One reason that this may be of interest is that they sold their own home to Lee De Forrest, the inventor of the Audion (the first working vacuum tube). Another reason is that this led to my being raised in wartime Richmond where during WWII Henry Kaiser built about 1,000 ships in Shipyards 1 & 2 (with 20 ways between them). Richmond, as a city of about 23,000 in 1940, wasn't really ready for accommodating about 100,000 ship building workers over the next five years so anyone that "was warm to the touch" was "drafted" and put to work doing something.

My grandfather managed the building and then administration of temporary housing for about 30,000 people while my mother went back to teaching (my stepfather already had a job as the controller of the Sir Francis Drake Hotel in San Francisco). The main problem however, was that initially there wasn't any time to build schools. Would you believe shifts - how about four shifts per day in elementary school class rooms shared by two teachers with each class being about 90 students in size! This was before busing so I escaped that because we lived on the opposite side of town. But my mother (equipped with a "B" gas ration card) commuted to her school every day where during each afternoon she taught about 180 students in two shifts. There were 5 rows of 8 desks, or 40 total. The kids sat two to a desk (or three if they were small enough) - and those that were left over stood at the blackboard!

Following my graduation from Richmond High in 1950, I entered UC Berkeley majoring in Engineering Physics - just about at the beginning of the Korean War. This led to a lot of us signing up for ROTC and committing to 24 months of active duty following graduation. That allowed us to finish school before entering the Army. This part of my story is pertinent to my hp memories because, while UC Berkeley was (and is) one of the top engineering schools in the World, it (along with any other school I ever heard of) provided absolutely no educational experience that prepares one for becoming a mechanical design engineer (more about this as we go along because interviewing prospective ME's was to be part of my job at hp ).

In any case, in 1956 my favorite US President, Dwight D. Eisenhower, decided to let us out three months early in an effort to balance the budget. Thus while still in the army (e.g., on leave), I found myself back in Richmond in April 1956 - with a new wife that I had brought back from Germany. Needing a job, I asked my uncle who had been sales manager and was at that time plant manager of American Brass & Copper in Emeryville (and knew everybody in the Bay Area) where I should apply for work as a mechanical engineer. Without batting an eyelash he said "Hewlett Packard". To which I replied "What's a Hewlett Packard?". He wasn't really sure - but he was darned sure that it was the best company in the Bay Area !

So the next day I drove down to Palo Alto and found hp at 275 Page Mill Road. I simply walked in and suggested to the receptionist that I would like to apply for a job (i.e., at the tender age of 24 I had never done that before as must be obvious)! So the conversation then went something like "Really, as what?". "As a Mechanical Engineer." "Does anyone know that you are coming - do you have an appointment?" "No, do I need one?" Well by then it was about a quarter to 12:00 so she said "Come back after lunch - I'll see what I can do." By then I began to realize that had made errors in my approach toward actually getting a job. But I thanked her and went off to find a hamburger - and came back at 1:00 hoping for the best.

Much to my relief, a few people (including Ralph Lee and Bruce Wholey) did interview me that afternoon. As it turned out, hp had purchased the microwave line of instrumentation from Varian a few years earlier and were anticipating extending the line upwards in frequency into the K and R bands. It is an absolute fact however, that until that very moment - I had absolutely no idea what a mechanical design engineer was nor the faintest concept of how he or she performed his or her job! Nothing in my schooling, high school or university, and certainly nothing in the army had prepared me for this opportunity - but there must have been something in my eyes that indicated a grasp of what might be required because about two days later a very generous job offer came in the mail.

I couldn't get to the telephone to accept fast enough! I was invited to return to Palo Alto to discuss practical things like filling out the necessary paperwork and getting a more detailed explanation of what I was going to be doing - along with some idea of where I might live. I next proceeded to buy a tract house (on the GI Bill) and bought furniture and appliances from a government wholesale outlet in San Francisco (I was still in the Army) - and then went off to Fort Ord for a week to actually become separated from the US Army (e.g., on May 9, 1956).

During the following week I rented a truck, picked up the furniture, and moved into the house on Diablo Ave. in Mountain View - which as a side story is notable because one of our neighbors was the Jobs family with young Steve being a very young child at the time - and perhaps even more notable because eight years later Steve's father was trying his hand at selling real estate. The first house that he listed and the first that he sold (e.g., within two weeks!) was ours. Anyway, back in 1956 everything was pretty well buttoned down by May 15th and I started work at the old hp plant at 275 Page Mill Road on May 16, 1956.

The "Old System" - or What They did with New Engineers before 1957:

The first thing that happened to a new engineer was that he or she spent considerable time out in the plant learning something about actually producing instruments. Electronic Engineers (hereinafter "EE's") spent six months out there with most of the time as test engineers - while Mechanical Engineers (hereinafter "ME's") spent three months with the first two months involved in doing most of the assembly jobs, a little plastic molding and some machining, and the third month trying their hands in a somewhat limited fashion as test engineers.

There were lighter moments of course. I remember a picnic to which we new engineers were invited. I can remember Tom Lauhon ( hp 's second Industrial Designer), Frank Ura (soon to become our resident expert in vacuum deposited films) and Lee Bodily (who later gained fame as the engineer that flew around the world with an Atomic Clock to finally prove Einstein's theory relating to time being a function of speed correct) being there. And then of course there was the occasional beer bust!

In any case, when a new ME had finished his period of factory acclimation, he or she reported to Don Borthwick and Ralph Lee - and in essence became the manufacturing engineer for the whole company. As such you ran around "putting out a lot of fires", and in the process were exposed to pretty much of everything relating to the company and really learned how it ran.

That started with a 17 week schedule generated by the marketing department. The 17 week schedule went to the husband and wife production control team of Keith and Mary Elledge. They knew what our stock situation was via an elaborate Kardex system - and caused orders to smoothly go to purchasing as well as to the shop and assembly areas on the basis of established lead times. Everything went pretty much like clockwork with very few back orders and little assembly line down time. In order to make all of that possible, material lists and Kardex cards all had to be correct - so creating them was a major responsibility of any project's ME. And of course, if the manufacturing engineer (e.g., in my time at that job - me) ever did anything that required modification of any of those items. He (that is I) was responsible for keeping everything moving smoothly and everyone that needed to know informed - and as I remember often getting Don Borthwick's approval.

But what was the general nature of the "fires" that needed putting out you ask? Well, they usually related to things that simply didn't fit - even though a particular instrument had been in production for some time. This often happened because different machinists made critical parts of an assembly, and even though parts made by any of the machinists were within tolerance - they all of a sudden wouldn't work together.

How can this be? It falls back on the responsible ME who did the part design and tolerancing in the first place. As I was later to find out, in high volume manufacturing (e.g., think auto manufacturing) they generally have a "book" on each part that includes an assembly tolerance "stack" drawing. The salient features of such "stack" drawings are the critical dimensions that govern an assembly's assemble-ability. For instance, if a part mounts in against a shoulder facing one way and in turn mounts a ball bearing against an internal shoulder facing the other, the axial distance between those shoulders is such a critical dimension. Thus if the responsible ME had dimensioned the part such that he or she "went around Robin's barn" to finally generate that axial dimension, then a tolerance buildup would occur and show up on the "stack" drawing. Then that would have been corrected by directly dimensioning the critical distance. This would have been followed by a tool engineer processing the part such that both surfaces were machined in the same set up.

Up until then however, no such procedure existed at hp. As a result, I ran into all sorts of what really amounted to fundamental dimensioning philosophy errors that had to be corrected. This often required rework or even replacement decisions. And this in turn might involve Kardex entry and part and/or material ordering issues (i.e., I got to know Keith and Mary Elledge quite well!). One small and seemingly quite simple instrument that I very well remember in this regard was the 476A Universal Bolometer Mount. This is because its dimensioning philosophy was really quite backward, and for the first time required me to make an informal "stack" drawing before re-dimensioning its critical parts.

An Unusual Opportunity that fell My Way:

It happened that the pilot runs of the then new 626A/628A Signal Generators ran into serious trouble during the Fall of 1956. Priced at $3,250, they were by about $500 the most expensive instruments in the line at that time. Or putting it another way, those deadlined pilot runs represented about $65,000 of sales out of somewhere just north of $25 million for the whole company that year. Or putting it yet another way, there was a lot of pressure on Larry LaBarre, the project's lead ME!

The problem was that there was a failure in the frequency drive mechanism used for tuning the klystron cavity. Specifically, the drive and anti-backlash mechanism therefor consisted of a slotted scroll-type cam with a yoke mounted pair of small ball bearings - one in direct rolling contact with one shoulder of the slot and the other mounting a (larger diameter) "tire" comprising inner and outer steel bands separated by perhaps 1/8th inch of molded low durometer rubber - resulting in the outer steel band then being compliantly loaded against the opposite shoulder of the slot. The failure mode? The bond between the inner steel band and molded rubber was failing on all 20 of the cam drives!

I suggested modifying the assembly such that three thin section ball bearings could be placed side-by-side on a sleeve with the center one having a larger inside diameter and being eccentrically positioned on an eccentric lobe of the sleeve. Then the sleeve was to be spring loaded (e.g., rotationally about the 1/8th shaft upon which it was mounted) such that the eccentrically mounted ball bearing forced the other two against the inside shoulder of a slightly modified cam.

Larry asked me to draw it up and get a prototype made ASAP. I did, and it worked fantastically well! Larry was very grateful and even went out of his way from then on to unofficially mentor me. But the only other observation that we heard was from Ralph Lee who turned my solution down flat because it added something like $10 (mostly in the form of more expensive ball bearings) to the cost of the instruments.

This led to me redesigning the assembly so that it could use three relatively cheap 1/4 x 5/8 ball bearings at the cost of slightly more machining cost involving some clearance machining on the supporting casting and an additional small sleeve so that the outside ball bearing could be assembled last on a smaller diameter portion of the spring-loaded sleeve. My memory is that outside of a tapped hole in the supporting casting for mounting the other end of the spring, no other modifications to either instrument were required. And so finally the pilot runs proceeded and the instruments were released for production (that lasted for more than 20 years because the 626A and 628A are still offered for sale in my 1977 catalog).

Then during the Winter of 1956/57 something really quite unusual happened. One day a newly hired fellow named Jack Riddle came by and introduced himself while leaning over my drafting table. Mr. Packard had just hired him away from a rising position in the management chain at Ford. Apparently, Jack's first assignment was to investigate various circumstances relating to establishing the first overseas manufacturing plant in Germany. In order to be able to familiarize himself with Germany, Jack's apparent first action was to find out whether anyone in hp 's cadre of salaried employees had spent any significant post-war time in Germany. I guess that since I was only about eight or nine months removed from having served in the Army in Germany (for 16 months), he had decided that I was the one to talk to.

The first thing I asked after he explained his mission, was where did they anticipate locating the plant? He answered "Oh, I don't know. We thought maybe somewhere near Munich." - to which I replied "I wouldn't do that.". Jack was surprised by that observation and asked me why, to which I replied something like "Well, besides more paid holidays there, I think that you'll find a stronger work ethic further west - generally in the Stuttgart area.". (And since I had lived in both areas I could fill him in with some detail.)

I have no idea whether the above had anything to do with the plant eventually being located in Böblingen, but roughly a year later Ray Demere started sending back little notes from Böblingen (that appeared in Watt's Current) relating to difficulties involved in living in early postwar Germany - for instance, things such as doing the laundry in the bathroom tub and hanging it about the apartment to dry! (That I couldn't understand, because in the BOQ's we always had a maid who took one's laundry at the end of each week and delivered it washed and neatly packaged on Monday with a bill for about 8 to 12 Marks ($2 to $3) - not to mention that every married Chief Warrant Officer or Officer above the rank of First Lieutenant seemed to have a maid (at about $50/month).

1957 - a Year of Transition:

Until 1957, ME's were located in a portion of the open administrative space as opposed to being in the laboratory with the EE's. This meant that there was a somewhat compromised team effort in getting out any new instrument. In fact, the common expression used for communication between EE's and ME's ostensibly working on a given project was "throwing a breadboard or design concept over the wall" (e.g., in either direction). But that all changed in early 1957 (February I think) with the first hint of divisionalized organization. Production engineering became its own profession whereby I was the last "temporary manufacturing engineer for the whole company" and finally became a full-fledged ME. The newly minted "professional" manufacturing engineers and the tool engineers were left in the open administrative space while we ME's moved into the lab.

The laboratory was about 48 feet wide (e.g., able to accommodate five columns of side-by-side 8-foot long EE workbenches plus two 4-foot isles) by perhaps a little more than twice that in length. That left room at the back of the lab for three four table arrays of back-to-back 5-foot drafting tables (e.g., with the four drafting tables each oriented parallel to the EE's workbenches) with a single four drawer filing cabinet positioned between each pair of facing drafting tables (fortunately, I don't remember any left handed drafting arms!). Each ME also had a 6-foot long workbench separated from his or her drafting table by at least a 4-foot space. All of that plus a 4-foot laterally running isle that separated us from the EE's resulted in us occupying the back 24 feet or so of the lab. That left room for perhaps eight rows of EE's in the front of us for a total of perhaps 56 individuals (e.g., although all of the available positions (especially in the ME section) weren't occupied). Amongst the group there were a couple of technicians and three of the ME positions were occupied by Carl Clement's burgeoning industrial design group (it became a group of three very soon with the addition of Al Inhelder).

There was a management shift as well. We no longer reported to Ralph Lee. In fact my new boss was Bill Myers. I want to especially mention Bill because he never seems to be mentioned in historical writings about hp . Yet Bill was very important to hp during the very important period spanning the early to mid 1950's as the company became the dominant producer of electronic instrumentation. During that period hp won all of a series of government contracts for developing high frequency signal generators and Bill was the responsible EE on most of the resulting projects. I believe that either he was, or that he along with Art Fong, were the development EE or EE's on the 614A, 616A, 618A, 620A, 626A and 628A signal generators. I only remember receiving one bit of advice from Bill: "When it came time to begin work on a new signal generator, the first thing I did was to walk up and down the aisles of the stock room to see if there was anything there that I could use again." That was it! In point of fact, working under Bill was a real pleasure because he operated on the principle of "If it ain't broke, don't fix it!", wherein I was allowed to create and design things without much if any impedance!

|

At first I designed simple stuff like the K & R band 370 Fixed Attenuators, 375 Variable Attenuators, and 752 Directional Couplers. With the exception of considerable help from Frank Barnett on the 752's (see further discussion below) these projects were just simple scaling (e.g., making them smaller) and paperwork jobs (e.g., material lists and Kardex cards) requiring little if any creative design. But then somewhere toward the middle of the year I finally got permission to design the P, K and R 532A Frequency Meters (i.e., a catalog picture of a P532A is shown at the left) as well as the K & R 382A Precision Variable Attenuators (i.e., a catalog picture of an R382A and a generally descriptive schematic picture thereof are shown hereinbelow next to a story about them).

It occurs to me that many readers may not know what a 532 Frequency Meter is - so with the aid of the elaborate disassembled view below provided by Marc Mislanghe, let me try to explain. The round polished bore in the cylindrically shaped object (hereinafter "cavity tube") that extends vertically from the waveguide is of course the instrument's cavity bore. As can be seen via the rectangular cutouts in the molded nylon base, the cavity tube is laterally displaced with respect to the waveguide's center. Thus a small oblong shaped opening formed at the edge of the waveguide (not shown but in the center of the bottom of the cavity) provides a path for small coupling currents to pass into its center when the leadscrew/plunger assembly shown at the lower right portion of the picture is tuned such that the cavity is resonant at the frequency passing through the waveguide (i.e., the currents in a waveguide run on the surfaces thereof while the electric field has its maximum value at the center of the waveguide).

The power so transmitted during resonance is lost and thus results in a small (e.g. 1.5 db) dip at a downstream detector as either the frequency is swept, or the cavity height altered. The silver-rhodium plated, non-contacting plunger has a series of nominal quarter-wave length long low impedance sections (three each) and high impedance sections (two each) - the idea being that the entrance to each low impedance section looks like a better short because a quarter wave-length away there is a high impedance transition that looks like an open circuit and so on. The plunger shown is typical of the P, K and R 532A Frequency Meters but not the larger G, J, H and X 532's (i.e., see a story about the G, J and, H 532's below) because they had two folded high impedance quarter-wave sections in order to minimize overall cavity height.

Actual construction details of the waveguide/cavity structure varied between the X, P, K and R 532's and the G, J and, H 532's as well because the smaller ones had soldered (together) waveguide and cavity tube portions while the larger ones used an aluminum casting with a large diameter bore to a shoulder just coincident with the upper inside surface of the (broached) rectangular waveguide sections at either end. Then a cavity formed from a soldered together cavity tube and bottom plate portions was fastened onto the bottom casting.

As far as the 532 project goes however, please notice that the above initial list didn't include an X532A. That is because there was an existing X532A that had been previously designed by a tool engineer named Doug Wright ( hp 's plastics and plastics tooling expert). It was built like a piece of tooling with the working parts made of tool steel and bronze. There was a robust acme threaded lead screw/plunger assembly that was heavily anti-backlash loaded with a die spring. The design was over constrained and even Doug wasn't happy with it. In fact, he said something like "Thank god they've put a mechanical design engineer on the project. I hope that you will redesign the X532A." The main functional problem with the design was that you could push laterally on the control knob and as a result move the plunger assembly vertically, thus changing the physical size and thus the resonant frequency of the resonant cavity without rotating the knob. That plus the difficulty of turning that heavily loaded lead screw and the cost of some of the heavy duty parts made the design appropriate for change in general and totally inappropriate for use in the higher frequency 532's.

So partly for that reason, and partly to take maximum advantage of almost all of the plastic part tooling that Doug had created, I designed and had fabricated prototypes of a whole line of X, P, K and R band 532's that were executed in a cohesive manner making maximum use of part interchangeability. The salient feature of the new design concept was that the control knob and dial were independently mounted on the aircraft torque tube ball bearing shown in the picture at the top of the cavity tube. A 1/8 inch diameter dual purpose shaft (i.e., that also mounted the black colored stop gear shown mounted thereon at the extreme right) acted as the driving member for a slotted cap (shown at the extreme left) that drove the lead screw/non-contacting plunger assemblies. The plunger was mounted via a simple ground thread/bronze nut combination in concert with a very light loading spring. The result was a substantially backlash and perturbation free rotating assembly that could be easily rotated by a single finger on the top surface of the knob.

Doug had innovated a novel way to fabricate a cylindrical dial made from grey nylon. First however, detailed calculations for the calibration of each dial had to be done. At that time (e.g., long before computers) that task represented about two man weeks worth of mechanical calculator and log table work (e.g., with a Frieden calculator that had square root capability and cost about $850 in 1957) in accordance with a somewhat complex formula from Terman's Radio Frequency Handbook. (I.e., including the later J, G and H 532A's and the 382's, I was to perform that process some seven times - the 382's being done in accordance with a db scale executed according to a cosine to the fourth power function as explained below.)

Then the tooling fabrication process began with an 1100 series aluminum cylinder being cut with an engraving tool, first a spiral track on a lathe and then by engraving each axially oriented frequency line on a milling machine (e.g., with the aid of a dividing head). Then the numbers were engraved. Next, a heavy jacket of nickel was electro-formed on the finished aluminum cylinder, which electro-formed nickel layer was then cut with a diameter and shoulder that would later be pressed into a plastic mold. Finally, the 1100 series aluminum cylinder was etched out with NaOH and the nickel master pressed into the mold.

The dials themselves began with grey nylon being injected into the mold. Then the internal male portion of the mold was withdrawn and cold air from an air gun blown into the molded nylon dial until it cooled and shrunk enough to be extracted (e.g., without "dragging out" any numbers etc.). Finally, the spiral groove was cut (on a lathe) to finish the dial.

(The P532A dial shown in the picture as well as all of the other later 532's and later M, K and/or R 382's have an aluminum dial with photolithographically generated lines and numbers. That development work was done later by a young ME named Jim Ferrell that we interviewed and hired (along with Tom Wirrick) during 1958.)

But in any case, Ralph Lee would have no change to the X532A. "Let's see first how the P, K and R band 532A's work out in practice." was his opinion and final statement on the matter. But as you will see below, that opinion turned out to be an expensive one.

|

As in the case of the 532's, it occurs to me that many readers may not know what a 382 Precision Rotary Waveguide Attenuator is, so this time with the help of the generally descriptive schematic picture shown at the left, let me try to explain. The 382's had a round rotating center section with rectangular-to-round transition (non-rotating) end sections at either end thereof. The transverse planes extending across the centers of both of the center and end sections represent thin mica cards with 50 ohm/square vacuum deposited resistive films (made by Frank Ura in his vacuum coating lab). An incoming E-field entering either end section is vertically disposed and therefore orthogonal to the first mica card whereby no currents are induced therein so there is no attenuation. But when that unattenuated "E-field Vector" arrives at the center section it divides into parallel and orthogonal E-field Vectors with reference to the center section mica card, whereby the parallel E-field Vector is completely attenuated leaving only the orthogonal E-field Vector to enter the final end section. That E-field Vector again divides into parallel and orthogonal "E-field Vectors" with reference to the final end section mica card, whereby that parallel E-field Vector is completely attenuated thus leaving only a final orthogonal E-field Vector, which final orthogonal E-field Vector represents the magnitude of the outgoing E-field leaving the attenuator as a whole. The outgoing E-field then is equal to the incoming E-field vector times the square of the cosine of the rotation angle of the center section (e.g., from horizontal). Since power is proportional to the square of the E-field, the power out is precisely equal to the power in times the fourth power of the rotation angle of the center section - and therefore not dependent on frequency.

As you will also see below, the 382 project ended with a different twist - but first here is the development story: One day Carl Clement said to me "Phillips Head" (he always called me that), since the rotary attenuator (in this case, pertaining to the K & R and much later M 382A's to be) is fundamentally a rotational device, why don't you make the whole instrument round with a concentric knob, dial and housing! Well, I was a young kid of 25 just a year out of the Army so nothing fazed me and I said "OK sure."

|

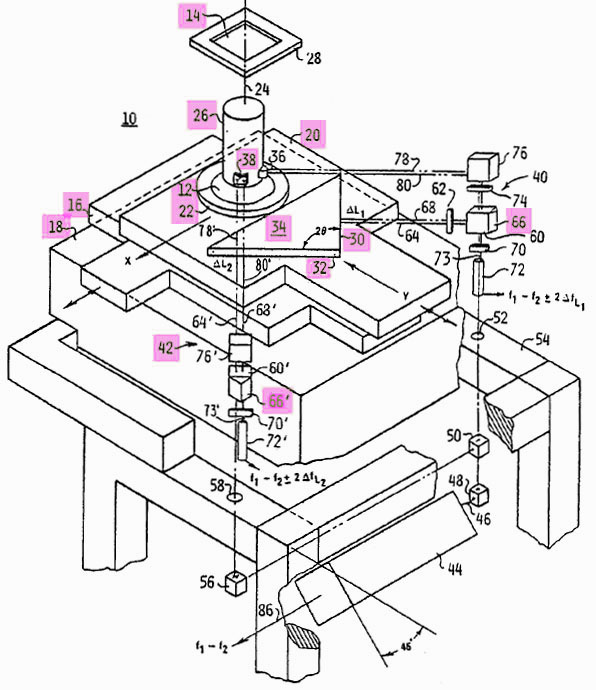

The problem with that of course was that the dial would have to rotate through about four turns in order to obtain acceptable resolution for the 90 degree total rotation of the center section. That meant that there would have to be a reduction ratio in the order of 16:1 between the knob/dial and the center section. I pondered the problem for a while before coming up with the thought that if I were to fashion a "strange" external planetary gear set with a first fixed "sun" gear and a second driven "sun" gear formed on the center section - with each having the same number of teeth, and then linked them by a pair of rotationally coupled planetary gears with each gear thereof having a lesser but identical number of teeth - then the center section wouldn't move at all as the planetary carrier was rotated! So then all I would have to do is back off from that by one tooth on either pair, whereby I should end up with an acceptable ratio. All of this was implemented in production form in the manner shown at the left (e.g., an R382A in the picture).

Actually such gear sets had been known out in "the real world" for a long time - but not by me or anyone else at hp as far as I knew. They were properly called "external differential planetary gear sets" (i.e., BMW's "Active-Steer" is currently implemented by such a gear set). In any case, I executed a design layout and part drawings of a prototype R382A and got the parts made in the tool/model shop (along with a hand made aluminum dial). Later when I received the parts they all went together and the fledgling R382A worked just fine.

But then one day Mr. Packard came into the lab and walked its length (with at least 40 pairs of eyes on him - mine included) and much to my surprise, he came straight to my work bench. Without speaking, he picked up my prototype R382A (and the P532A) along with some misc. spare parts to inspect them. After about five minutes he turned to me and said "This is very interesting. I want you to know that we will support you." and that was it - or so I thought.

Seven years later (e.g., long after we had moved up on the hill to 1501 Page Mill Road), Walt Disney showed up at the company's 25 year anniversary party with one of Bill Hewlett's original 200A oscillators that he had had cleaned up and gold plated. Then one or two weeks later a free-standing glass case with two shelves appeared in the front lobby. The (gold plated collector's item) 200A oscillator occupied the top shelf and an R382A attenuator such as shown above occupied the bottom shelf! That display was there for at least the next 15 years that I know of because over much of that time I fairly often came up to visit an hp patent attorney named Ron Griffin who was moonlighting for me (with hp 's permission of course).

But getting the 532's and especially the 382's into production was more than a paperwork exercise! There was a tolerance buildup problem on the 382's. This was largely because the width tolerance on the torque tube bearings used at either end of their center sections almost consumed the total allowed end clearance variation! What to do? Well somehow (sure could have used "Google"!) I found an obscure product called "peal washers" that would be fabricated in accordance with your drawing from a stack of lightly bonded (e.g., together) 0.002 inch thick layers of shim stock. So I utilized such washers of two different sizes in each attenuator with each washer peeled selectively in order to get the required axially oriented clearances. The problem then became formalizing the whole assembly process in an organized fashion so that ordinary mortals could assemble the instruments efficiently.

Well the gods were with us that summer - because in much the same way I had during the previous year, in the front door walked a Detroit trained tool engineer named Norm Bowers! Norm had worked at GM since WWII (when he was in the Navy) - much of that time on tooling design and processing parts for their Hydra-Matic transmissions. Fortunately, Norm was hired and immediately assigned to my 532 and 382 projects. I learned more about the practical side of my trade from Norm than from everybody else combined! With his help and direction I redesigned many of the parts on both of the 532's and 382's, as well as working out a specific assembly procedure for the 382's - particularly with regard to selection of the "peal washers".

The assembly procedure involved use of a twice-sized combined assembly and stack drawing (drawn on "D" size paper yet) the like of which no one in the company had ever seen. Except for Ralph Lee of course, who claimed to have done something similar on the 476A Universal Bolometer Mount - yikes! (By that time I had long since learned that with Ralph, it was better to let "sleeping dogs lie" - so I let that one pass!) In any case, both lines of instruments went through their pilot runs without issue and were in the catalog for many years.

Before going on, I should mention the fact that I was fortunate to learn from a lot from others as well - from both inside and outside the company. For instance, at that time we couldn't make the fixed sun gear in the 382's in house because it was located next to a larger diameter shoulder, so I learned about gear shapers from a gear guy up in Belmont. We also didn't do our thread grinding and lapping (which was required for the 532's), so I learned a lot about that as well as about some special machine tools and lathe tracers from Sam Campana at Tydeman Machine works in Redwood City (who said to me "anything you want son, as long as I get my $7 per shop hour!"). We did do our own die casting (as well as plastic molding) but didn't have other kinds of in-house casting capability (or quite frankly, real casting design capability either), so I really learned a lot from Wayne Masingil at Reliable Pattern & Foundry down in San Jose. And finally, since the G, J and H 532's would have broached waveguide sections, I later learned something about broaching from Pioneer Broach in Mountain View.

Incidents Involving either Mr. Hewlett or Mr. Packard:

When you acquired a drafting table (e.g., equipped with a 24 inch K & E drafting arm) you also got a production chair, hole template, compass, mechanical drafting pencil, eraser and an erasing shield. But a new motorized electric eraser had recently come on the market (e.g., priced at about $15), and we all wanted one. In fact, one of the other ME's named Larry Renihan decided to build one using a shaded-pole fan motor. He had an eraser holding tube assembly for it fabricated in the tool/model shop. The assembled eraser was controlled by a taped-on micro switch. I thought that to be ridiculous and simply ordered a real one through purchasing. When it came it became the talk of the department.

The trigger for everyone getting one occurred one day when a couple of folks including Ralph Lee congregated around Carl Clement's area to kibitz on the industrial design group's concepts for the first EKG machine that wasn't in a roll-around wooden box (a future product of the Sanborn Division). A latecomer to the seemingly ad-hoc meeting was Bill Hewlett who finally came into the lab and was walking up the isle - just when I happened to reach for my eraser and turn it on for use in the intended fashion. Ralph heard the eraser running and immediately yelled out to Bill (who was still easily 40 feet away) "Come here Bill, you've got to see this!". He repeated this at least twice more before Bill got there - and then he said "You've got to see what Phillips has!". Both of them came over and looked - to which sight, Mr. Hewlett simply grunted. Anyway, soon everybody acquired an electric eraser.

Its no secret that hp hadn't exactly set the world on fire in 1956 with the introduction of the 130 and 150 Oscilloscopes (especially the 150), although as my friend Dick Reynolds often said later, "I did the one (e.g., the 130) that worked!". But the biggest problem was that both weren't profitable and something had to be done to take cost out. They both featured an elegant, but costly, bayonet type scope bezel that mounted hp 's 196A scope camera. So Carl Clement's group was given the task of designing a simpler and less costly bezel that would still enable mounting of the 196A scope camera.

Amongst the three of them they came up with three alternate designs and Al Inhelder prepared a four-quadrant display panel that had a physical model of the bayonet type scope bezel along with each of the three competing potential replacement designs - plus a bullet listing of their features and their cost structures. Al set the display up on the unoccupied drafting table (e.g., the one that you ran into at the end of the main isle) and they called a meeting of the then newly minted Vice Presidents to have them make a decision on which version to produce.

Actually the choice was obvious because the most functional and esthetically pleasing potential replacement design was also the least expensive. But what ensued was a demonstration of the uselessness of trying to decide anything by committee! Everyone was trying to be diplomatic and objective - and as a result indecisive. This went on for what seemed like about 30 minutes or so until Mr. Packard arrived on the scene. It seemed that he had been looking for Noel Eldred and was told that he was back in Carl Clement's area for a meeting. Dave asked what they were doing. Of course he could see the display and ignoring the blather being presented to him, commenced reading the information presented in each quadrant. After about 30 seconds he simply said, "We'll do this." pointing to the obvious choice - after which the meeting immediately broke up and everybody went back to work! The result was the familiar scope bezel that was used by hp for as long as I can remember.

Everyone seems to know about Packard's dramatic visits to many of hp 's plants during the economic troubles of the early 70's. Well during early 1957 there was a "warmup episode"! One of the nice things about suddenly being part of the lab was going to the monthly lab luncheons that were held down at The Old Plantation Inn on the Northwest corner of El Camino and San Antonio Road (which eatery was torn down a few years later and replaced by an elegant strip mall).

The "fan was hit" during my second (and the last such) lab luncheon. Pete Lacy and Dan Wheeler received an award of $25 from Bruce Wholey for having an article published on the (then hopefully) soon to be released 680 series of Electronic Sweep Oscillators. Then Bruce told us that Mr. Packard had asked to be invited so that he could address us. That address and the events that followed went something like the following:

He began with "Well, I'm sure glad that you got that article published. Now where the hell are the instruments!" That was followed by a sternly presented laundry list of various other projects that were behind schedule and/or over budget that lasted for perhaps 10 minutes - after which he simply turned around and left!

We all sat there in stunned silence for perhaps five minutes after which Bruce got up and said "Well, we better go back to work.". No one was in any great hurry to do that so Mr. Packard probably had about a 10 minute head start on us. But during that 10 minutes he had gone through the lab leaving a few choice notes here and there as he went - the most notable one of which said "We'll have no more of this! P ", which note was placed on some poor soul's workbench next to a prototype 120A oscilloscope "space frame" (e.g., borrowed from the existing 130A) that Dave had twisted into a pretzel! It seems that that "space frame" involved expensive fabrication of a significant number of sheet metal pieces and complex welding that required time consuming assembly and welding operations in a special welding jig. That's why the 120A had a completely different set of sheet metal parts than the earlier 130A!

But unfortunately, the events of that day didn't really seem to make any difference in the speed and efficiency with which very many projects moved through the lab!

Moving Day!

We all came in one Saturday in February 1958 to actively participate in "moving day". Engineering moved from the old plant at 275 Page Mill Road up the hill to the Upper Floor of Building 1, 1501 Page Mill Road. Now after 53 years my memory of the detail of that day is admittedly a little hazy, but I do remember that we engineers did a lot of the actual work! I remember moving a lot of desks and work benches with an electric fork-lift truck (e.g., involving driving on and off the freight elevator in order to get them to the upper floor). The really neat thing however, was that we ME's finally got real functional work benches!

Those workbenches were 8 feet long by 30 inches deep and were fabricated in welding and wood working shops located down the hill behind the old plant at 275 Page Mill Road (e.g., next to the Olive Avenue fence in an area that would later become part of the parking lot behind the Agilent building). As it had been down the hill at the old plant, a typical setup for a pair of EE's consisted of two workbenches separated from the next column thereof by 4-foot wide isles with about 5 feet separating the workbenches from a pair of standard 30 inch by 60 inch steel desks that had in house fabricated bookcases and a shared telephone between them. The desks often had a file cabinet between them with the shared telephone placed on top. Sometimes however, there would be a 5 foot wide drafting table there instead. EE workbenches had two sets of three drawers, multiple power strips and a Variac.

A typical setup for ME's differed in that there would be two drafting tables at either end of the shared space with a desk (and shared telephone) in between. The drafting tables were usually set orthogonally such that the drafting arms wouldn't hit the back of the workbench in the next row. An ME's workbench differed in that it had two large flat drawing file drawers at one end, and a Variac and single three drawer set at the other instead of the two sets of three drawers.

I may be biased, but I still think that some version of that type of working environment is the most desirable one possible. I realize that old fashioned steel desks just will not work in the age of computers and printers, but those workbenches were simply marvelous! I know that because we ME's didn't get them until moving day. Our workbenches down at 275 Page Mill Road had the drawing file drawers but were only 6 feet long. They had no back stop or shelf, minimal power strips, and no Variacs. But even after the move Ralph Lee's group of production and tool engineers (unfortunately including my new friend Norm Bowers) were still stuck with them! In any case, we suddenly became formally divisionalized with the Upper Floor being laid out as follows:

Ralph Lee's production and tooling groups occupied the Northeast corner of the floor (next to the freight elevator) and were separated from the Microwave Group (which Microwave Group was by then formally managed by Bruce Wholey who sat nearest the center isle) by a row of "armpit-to-armpit" workbenches. There was room for three two-person setups and three isles between the window and the center isle. They were arranged in columns that at first were just long enough (maybe only three rows) to accommodate perhaps only about 18 engineers. Then there was quite a gap from us to a similarly sized and laid out group of setups of the Frequency and Time Group (under Al Bagley) that was located in the Northwestern corner of the floor.

Barney Oliver had his office at the Eastern end of the South side of the floor. Then moving westward from there (and separated physically by about a 7 foot tall wall) was Carl Clement's group, which was separated from the then Audio-Video Instrumentation Group by another wall. Then there was another huge gap to the Oscilloscope Group and finally the newly enlarged library in the very Southwest corner of the floor. All-in-all, we couldn't figure out how in the world all of the remaining space could ever be filled up. Well as it turned out, it was only a little over two years before our Microwave Group had to be moved to the Lower Floor of a newly constructed Building 3!

Soon thereafter, the tool and model shops were moved up the hill to the Lower Floor of Building 1 with the model shop located pretty much directly below Ralph Lee's group in the Northeast corner, while the tool shop was located generally from the Southwest corner and on into the center area of the South side of the floor. The rest of the Lower Floor had some labs on the north side that would soon be taken over by Larry Hubby while a small auditorium occupied the remaining Southwest corner.

1958 Through 1960 - a Busy Time for Me:

As I remember it, the first thing Norm Bowers and I got involved in following our move up on to the hill was a "clean-up" partial redesign of the X532A per Ralph Lee's dictum. We spent a lot of time cleaning up details, and in particular, getting rid of an over-constraining shoulder that compromised lead screw/nut function. I also remember a lot of paperwork involved in making such a significant change in an existing in-production instrument because we had to obsolete a number of parts and straighten out inventory in the midst of releasing a production run of 100 of the modified X532A's. In fact, the paperwork burden was probably something like an order of magnitude more than that involved in the short time later replacement of the X532A with the X532B! In any case, Norm seemed to be crushed when he found out that after all of that effort it really didn't work much if any better than the previous version (one could still change the resonant frequency by pushing sideways on the knob). Anyway, after the success of the P, K & R 532A's, Ralph was finally convinced and so we released the X532B into production!

Now I'm probably going to get the chronological order of things screwed up from here, but please humor an old man! Perhaps the physically larger G, J and H 532's were next. In any case, the functional nature of those designs was similar to the higher frequency instruments but they differed considerably in physical design. It was deemed that the complexities and tooling costs involved (e.g., relative to the expected sales volumes) ruled out larger versions of Doug Wright's plastic parts, so the resulting structural design involved aluminum castings with the above mentioned shell molded and then broached waveguide sections on either end. The top side of the castings had a bored out area in the middle that accepted the resonant cavity portions of the instruments.

The 434A Calorimetric Power Meter:

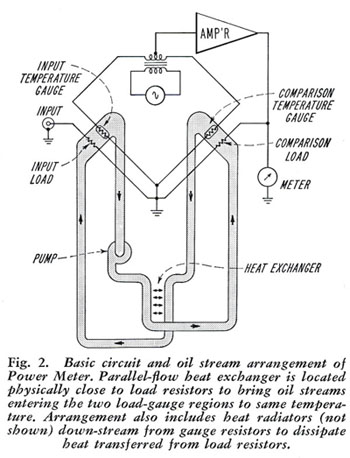

I'm going to guess that the next thing to come along was the 434A Calorimetric Power Meter. The general nature of the instrument was quite unusual. It was hp 's only instrument that had to have its oil level checked before it was turned on - and its oil flow rate checked before applying an unknown input power to its input coax terminal! In fact, the instrument's front panel had windows that revealed an oil reservoir and an oil flow indicator, which windows are respectively labeled "OIL LEVEL" and "OIL FLOW". A simplified diagram depicting the 434A's operation is shown below to the left, while the following quoted "Circuit Description" from the hp 1959 catalog provides a pretty good explanation of its operating principle:

|

"The Model 434A consists of a self-balancing bridge which has identical temperature-sensitive resistor (gauges) in two legs, an indicating meter and two load resistors, one for the unknown input power and one for the comparison power. The input load resistor and (a first) gauge are in close thermal proximity so that heat generated in the input load resistor heats the gauge and unbalances the bridge. The unbalance signal is amplified and applied to the comparison load resistor which is in close thermal proximity to the second gauge so that the heat generated in the comparison load resistor is transferred to that gauge and (substantially) rebalances the bridge."

"The meter measures the power supplied to the comparison load to rebalance the bridge. The characteristics of the gauges are the same and the heat transfer characteristics from each load are the same, so the power dissipated in each load is the same, and the meter may be calibrated directly in input power."

"The power measurement is accurate, because flow rates through the two heads are the same and the oil enters the heads at (virtually) the same temperature. To insure constant temperature and to bring the streams to (substantially) the same temperature, they are passed through a parallel-flow heat exchanger just prior to entering the heads. Identical flow rates are obtained by placing all elements of the oil system in series.".

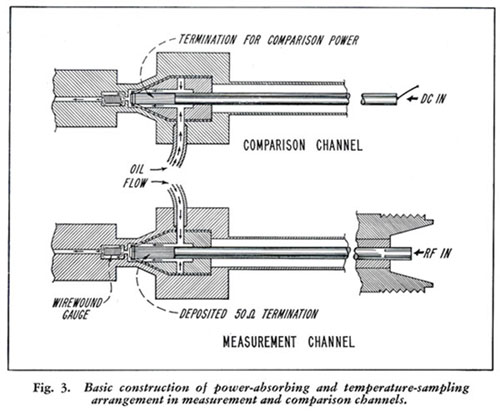

The "heads" are shown in considerable detail in the view below:

Please notice the thin electro-formed shells that terminate the co-ax line id's. They were hp 's first electro-formed parts - 0.005 inch thick Nickel with an etched-out aluminum mandrel.

OK fine - but all of that had been so for many years of development time. The problem was that the 434A still didn't work because of noise, which noise had a magnitude of more than half-scale whenever the 10 mW range was selected! The problem was explained very simply by Bruce Wholey as: "The gauge wire is at least as good a strain gauge as it is as a temperature gauge.". Clearly the problem was that the gauge wire was exposed to turbulent flow, so my task, and ultimately my principle contribution to the by then more-or-less 5-year old project, was to find a way to smooth the fluid flow and shield those wires from it as much as possible - while still maintaining the functionality of the instrument. I also contributed a more efficient radiator that was only about one fifth the size of the previous one - all of this in time for the 434A to be released into production in time to make the 1959 catalog.

|

That more efficient radiator is shown in the picture at the left. As you can see, it is located next to the instrument's fan motor right behind the fan. It has two short cylindrically shaped finned (e.g., roll formed) tubes. Previously, the radiator had six such tubes each almost twice as long - all set in front of the fan. The secret was that I bored the inside of the tubes such that they had a more-or-less cylindrical bore and then inserted copper rods configured such that the oil had to flow through a radially thin film proximate to the more-or-less cylindrical bore of the tubes. I made an attempt to obtain what would have been my first patent on that idea, but the examiner dug out an old (e.g., from the early 1900's) patent relating to something used on steam engines. So John Chognard ( hp 's first, and still at that time only, in house patent attorney) thought that relating an hp instrument to 50 plus year old railroad steam engine technology was a big joke and didn't argue the case further!

But then a little later came the USAF with its Ballistic Missile Early Warning System ("BMEWS"). Three installations thereof were to be pointed north from remote regions of Canada and England for the purpose of looking for inbound missiles coming over the North Pole. The Air Force had a requirement for measuring the power applied to their RADAR antennas and chose the 434A for that task - except it had to be packaged differently in order to be compatible with their other rack mount instrumentation. Basically (e.g., from my perspective) it was a matter of providing a 5/16 inch thick by 26 inch wide panel and gold alodyned sheet metal - including that odd-ball panel.

However, John Minck swears that they wouldn't accept the instruments without the pump/motor combination conforming to "military specifications". I never knew anything about that problem - because when the instruments were released for production, everything in them including the pump/motor combination, was the regular production stuff (except of course for that alodyned panel and other sheet metal).

The 938A and 940A Frequency Doubler Sets and the DY-5636 RF Test Set:

Anyway, somewhere along in there came the 938A and 940A Frequency Doubler Sets. They were enabled by really clever conceptual EE design work by Russ Riley who became my "cell" mate for the duration of that project. His contribution was to use a broadband crystal-harmonic generator element for coupling energy from an M-band waveguide 9-to-13.25 GHz source to an 18-to-26.5 GHz output issuing via K-band waveguide (e.g., in the 938A), and from an N-band waveguide 13.25-to-20 GHz source to a 26.5-to-40 GHz output issuing via R-band waveguide (e.g., in the 940A). That miracle was accomplished in a soldered assembly that comprised an elaborate orthogonally disposed soldered assemblage of the respective waveguide sections - except that in each case the larger waveguides were tapered into a ridged waveguide section having the nominal dimensions of either of the smaller waveguides (e.g., made possible because of the extended frequency range of ridged waveguide). We would later make use of such tapered and ridged waveguide in the 11518A, 11519A and 11520A waveguide adapter accessories for the 8551A Spectrum Analyzer, which later work was to be made a whole lot easier as a result of the enhanced electro-forming capability we gained later in the early 1960's higher frequency microwave work.

|

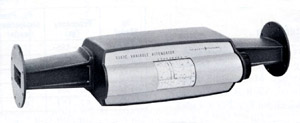

In any case, the 938A and 940A Frequency Doubler Sets were functionally configured in a similar manner to the 626A/628A Signal Generators with a directional coupler connected power meter and a 100 db precision rotary vane attenuator. The 100 db precision rotary vane attenuators used in the 626A, 628A, 938A and 940A as well as later in the DY-5636 RF Test Set comprised two serially ganged rotary vane attenuators having a 180 degree bend interconnecting section (e.g., with its own unique resistive film coated mica card) coupling their two center sections, as well as normal input and output end sections.

The two center sections were simultaneously driven by an elongated double worm shaft driving worm gears formed on each with their orientations controlled by a knob and three-turn dial as can be seen in the picture of a 940A shown in the upper picture. As noted above, Larry LaBarre had designed the original M and N band versions of the 100 db attenuators respectively used in the 626A and 628A, so I merely duplicated that basic design for the other instruments. The interesting thing about them however, was that they couldn't be tested because we could only detect power levels through about 50 db of their 100 db ranges!

The strange looking cabinet shown in the picture came about because the 938A/940A's were required to physically support any of the 626A/628A Signal Generators, 686C/867C Sweep Generators or the later 694A/B Sweep Generators (e.g., while they were stacked on top thereof) and thus had to be strong enough to support any of them. One complicating factor was that the 626A/628A Signal Generators were narrower than the 686C/867C Sweep Generators that were packaged in the old 10.5 inch Ralph Lee designed cabinet, or the 694A/B Sweep Generators that were packaged in one of the Clement series of cabinets.

But then a strange thing happened. I was approached by a newly hired ME from the Oscilloscope lab who had the problem of packaging what would become the 1100A Delay Line - which instrument would have to similarly support heavy oscilloscopes. He thought that the packaging concept used in the 938A/940A was just the ticket. So after he explained all of this to me, I gave him prints of the sheet metal parts whereupon he went off happy as a lark.

His boss apparently didn't like the homely appearance of the 938A/940A however, and didn't want anything that resembled them in his lineup of instruments, so the project apparently died - except that it didn't stay dead. Some time later, a more seasoned ME came over and repeated the whole process. This time it stuck, as you can see in the lower picture - where that ME did me one better by providing foot receptacles.

|

The last thing to come along (e.g.,before we moved down to the Lower Floor of the then new Building 3 in 1960) was the news that I was being "loaned" to Dymec to design something that was to be called a DY-5636 RF Test Set, a resulting 1963 catalog picture of which is shown to the left. Other than the above mentioned design of an H-band 100 db precision waveguide attenuator, it was essentially a packaging job wherein I packaged a lot of stuff into a 14 inch high transit case.

A Taxi Ride with Mr. Packard:

Dymec was located down in the old plant complex (up until the big move they had been located in the even older "Redwood Building" at 375 Page Mill Road). This meant that I had to make a few trips down the hill. I wasn't the only person that had to do that of course so hp had a "bus" (e.g., a Chevy sedan) service that ran back and forth between the front entrances at 275 Page Mill Road and the Southwest corner of the then new Building 3.

Now Mr. Packard had his own parking places right outside of private entrances to his offices at each plant whereby you would think that he would just drive between the plants. None-the-less, on one of those trips back up the hill my seat mate in the back seat of the Chevy sedan - was Mr. Packard! And as we pulled up to the new main Building 3 entrance he exclaimed in a manner that betrayed his small town Colorado upbringing, "Sure is fancy isn't it!".

1958 - An Introduction to Interviewing:

As suggested above, I came to be included in the ME interviewing cadre in 1958. I was informed of this by Ralph Lee who admonished me as follows: "Remember, these kids have only been to school, they don't know anything!" Now while I basically agreed with that sentiment, I certainly wouldn't have been so blunt - but Ralph went right on next saying "I just ask them something simple like 'does Young's Modulus in a piece of steel change when it is hardened?' If they answer no, I figure that they were at least paying attention in school so they must be all right!" I frankly thought that was ridiculous because it seemed to me that what we ought to be primarily interested in how a candidate might go about attacking a difficult design problem (plus of course, we primarily dealt with aluminum, brass and copper).

So I adopted a procedure of presenting either of the 532 or 382 design problems to interviewees in order to see how their thought processes would work when confronted by a tough thought provoking design problem. I have continued to use that method to this day, and up until the 1990's it always worked well. Sometime during the early 1990's however, I was abruptly stopped during such an interview by a candidate who was about to graduate with honors from the University of Michigan. After less than five minutes he stuck his hand out right in my face - and said "You're doing this all wrong! You don't understand, you're asking the wrong questions. They are too difficult for me to answer! They didn't do that at Ford.". And with that, he immediately turned around and marched out the door! Otherwise (and maybe even then), it has never failed to give a good idea about the suitability of a candidate.

Strangely, we found that candidates from the smaller mountain state schools were generally the most likely to be acceptable. In fact, Brigham Young University became our favorite school. I went through four candidates from my own school (e.g., UC Berkeley) before I was able to recommend one (i.e., he had been a Southern California hot-rodder while growing up).

While I escorted the first one into our area (at 1501 Page Mill Road) he had a troubled look on his face. When I asked him what was wrong, he replied "Where are the engineers?" Then the conversation went on something like this: "They're all around you." "No, I mean that all I see are people working at desks, drafting tables and work benches." "What do you think engineers do?" "Oh, I thought that you would have technicians and draftsmen doing that sort of work and the engineers would be in offices." To which I replied "If we could hire technicians and draftsmen to the kind of work we are doing here, we wouldn't need you right!", end of interview.

Mr. Hewlett had an idea that he would like to see a plant in India. So the next thought was that we should interview a mechanical engineering student from India with the idea of bringing him into the plant for a long enough time for him to be "inoculated" with "the hp way" - after which he would return to India and open a new hp plant. That led to my assignment to interview such a student from UC Berkeley (who as it turned out, lived up there at The International House).

The appointment time came and went - and no interviewee. But then suddenly at least an hour and a half later came a phone call from the personnel department saying he's been here all along! It turned out that he had parked in the lot outside Building 1 and walked into the inter-building passageway through the side door - and just stood there for well over an hour! Art Fong was the person who finally asked him if he needed help (e.g., after Art had walked back and forth to Building 3 through that passageway and still saw him standing there). So when I went to get him, I asked "Why didn't you ask someone for help?" He replied, "Well, I had no way of knowing the 'cast' of any of the various people I saw. After all, if it turned out that a person was of a higher cast than myself, I couldn't talk to him - and if such a person were of a lower cast than myself, I wouldn't talk to him!". It is my understanding that that episode cancelled any early plans for establishing a plant in India!

Then there was the graduate student who was being mentored by a professor who was a specialist in "four bar linkages". First he wanted to configure a 532 with a four bar linkage drive instead of a lead screw. Then when I gave up on that, I tried him on the 382 with its multiple turn knob/dial controlling the position of the center section that only went through a quarter turn. Same result, he wouldn't have it any other way than trying to figure out how to fashion a four bar linkage that would do that! End of interview.

And then there was the young man that Bill Girdner wanted to hire for his tool engineering group. My opinion was that he couldn't think in the abstract. That is to say he didn't seem able to grasp concepts and plot any sort of path toward solving a problem. So my recommendation was "do not hire".

But a few weeks later, there he was in the tool engineering department. That was the first (and I think the only time) that a prospective ME that I had turned down was hired. But then again, Bill Girdner came over to see me about six months later and said "We just had to fire that young man. So I looked back through his interview reports to see what we had missed. You were the only one that said 'do not hire'. How did you know?"

hp's Relationship with Stanford University:

In his book entitled The HP Way - How Bill Hewlett and I Built Our Company , Mr. Packard records their long collaboration with Fred Terman of Stanford University relating to getting them (as well as Ed Porter and Barney Oliver) interested in forming the company, and then his meaningful help in actually getting hp off the ground. Over the years both Dave and Bill were significantly involved with and made very significant donations to Stanford. But the specific action that affected me as well as a number of other hp engineers was Packard and Terman's particular collaboration in 1954 that established the Honors Cooperative Program, which program allowed qualified hp (and others from other companies as well) to pursue advanced degrees at Stanford. We hp employees still received our full hp salary while going (part time) to Stanford on company time. In fact, during the period of 1958 through 1962 when I was a participant in the program, hp also paid half of your tuition and book expenses. Plus - since I also had the GI Bill, things pretty much broke even financially for me!

Then a couple of unique things happened as the Spring 1960 Quarter at Stanford was coming to a close. The ME Department at Stanford had decided to institute a Mechanical Design Engineering course during that school year. The entire spring quarter involved the students being given the same fairly difficult mechanical design problem and then being required to execute their design concepts to the point of layout and assembly drawings. The problem the ME Department faced as the end of the quarter approached however, was that none of the department's professors felt qualified to judge and grade the results! So they came to a really creative solution to that new problem. They asked hp and a few other local firms (including IBM, Food Machinery and Ames Lab as I remember) to each select and send an appropriate mechanical design engineer to participate in a two day judging panel that would score each student's design. I was chosen to represent hp on that panel.

There was a wide range of quality in the students' work as you might expect. What you might not expect is that generally speaking (e.g., as the lead instructor told me privately), the most disappointing work had been done by their "best" students (e.g., the ones having the highest grade point averages), while the best work was done by the "worst" students (e.g., the ones having the lowest grade point averages). In point of fact, there was one really outstanding design that had been done by the student having the lowest grade point average of all - a young man named Tony Badger. I was so impressed by his work, that after the judging was over I asked Tony to interview at hp . At first he was doubtful saying "They'll never accept me because if I'm lucky, I'm going to graduate with a D- grade point average.". I assured Tony that I would sponsor him and that I was sure that I could influence the powers to be to recommend hiring him.

Well, as it turned out that promise was pretty hard to keep. But in the end Tony was hired (e.g., by the Microwave Division), and on a Saturday in June we both graduated - Tony with his Bachelor of Science degree, and me with an MS! At that time, we had a pair of projects that were in trouble from a mechanical design perspective - the 8614A and 8616A Signal Generators to be. Fortunately, when Tony came to work he was assigned to those projects, and with a minimal amount of mentoring did a great job designing those instruments.

But this story has to give one pause. Do our universities have the faintest clue about how to go about properly educating our young prospective ME's?

1960 Through 1963 - Management Philosophy Changes:

Besides the 8614A and 8616A Signal Generators, there was another, and even more important, project on the horizon, the 8551A Spectrum Analyzer. It was to be one of the most complex (mechanically as well as electronically) and expensive instruments in the company's history at the time of its introduction. Frankly, I couldn't understand why Bruce Wholey hadn't just previously asked me to be responsible for the mechanical design of all three, as he had a year before with the DY-5636 RF Test Set. If that had happened, they would all have gotten into production earlier - probably about a year earlier in the case of the 8551A. But it was the new era of establishing "proper organization, personnel development and reporting". The practical result of that was that each project had its own management and staff of engineers - with no cross fertilization. As far as the 8614A/8616A project went, it seemed early on that the most important thing was introducing the use of PERT Charts for managing a project.

Now as I saw it, PERT Charts had earlier been invented over at Lockheed as part of their effort to convince the government that they really needed their many thousands of "desk jockey" engineers (who would largely find themselves unemployable during the Nixon recession of the early 70's) - when the real design work on the Polaris and Poseidon rockets had been, and was still being done by relatively small groups of real engineers.

The point of creating a PERT Chart was that it highlighted the critical path to project completion. But the main task with the 8614A and 8616A Signal Generators was to efficiently repackage much of the old stuff from the 614A and 616A into 5-1/2 inch high Clement cabinets (along with a novel linearizing cam gear drive and perhaps some new solid state components). So obviously, the critical path involved ME design. I guess that that had something to do with Tony Badger being assigned that task as soon as he came on board. Fortunately, Tony had inborn and/or pre-trained capability and was able to contribute effectively with minimal mentoring as opposed to the training periods described above.

In any case, this change in management philosophy resulted in me being confined to designing even higher frequency waveguide test apparatus (e.g., to 90 GHz). The big problem was that tolerances were getting much tighter (e.g., as tight as +/- 50 millionths of an inch in many cases) so entirely new manufacturing processes were required. We spent a lot of time developing the enhanced electro-forming capability alluded to above. This was mostly an in-house effort although I got some help from the machine and plating shops over at Stanford where they were developing electro-formed sections that were candidates for use in the mile-long linear accelerator (SLAC) (e.g., to be built out behind the Stanford golf course and more-or-less parallel to Sand Hill Road).

We had two major problems: Heavy electro-formed copper tended to form "Popeye Elbows" on male corners - along with voids at anything that resembled a female corner. And of course, the mandrels used for the electro-forming process had to conform to the tighter tolerances. Thus a lot of the work involved new methods of machining. I especially remember that Bud Kincaid in the tool shop and Thurlow Murray in the model shop contributed significantly in that effort. One especially difficult problem was in making the highly accurate and yet highly polished small stainless steel mandrels required for electro-forming the rectangular-to-round end sections for miniature versions of the precision variable attenuators described above (the lower frequency and therefore larger ones were all die cast). But some of the mandrels were relatively simple shapes such as rectangular ones for short sections of straight waveguide, or round ones for the frequency meter cavities - for which relatively simple mandrels could be machined from 1100 series aluminum and then later etched out of a finished electro-formed part. More of that below, but meanwhile please consider the following:

A Superheterodyne Receiver at 90 GHz!

One thing of note that was accomplished fairly early on in this program was the implementation of a superheterodyne receiver that for the first time could actually measure the performance of a 100 db attenuator - that is if we had had one at 90 GHz! Keith Hunton suggested using a motorized phase shifter having its center section turning at 500 revolutions per second (e.g., 30,000 RPM!) in order to generate the frequency shift of 1,000 Hz that was required in order to enable Keith's concept.

|

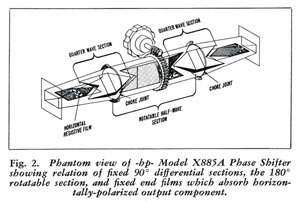

Frank Barnett's 885 phase shifter design involved structurally similar (e.g., to the 382 series) rectangular-to-round end sections coupled to a round center section. But instead of the full length resistively coated mica cards, they had dielectric blocks (hereinafter "blocks") of a selected short length positioned in the end sections that were physically set at an angle of 45 degrees to the incoming and outgoing rectangular waveguide - along with a single block of a selected longer length positioned in the rotatable center section as can all be seen in the view to the left. They also had short resistively coated mica cards positioned near the waveguide flanged ends of the end sections in order to absorb any residual horizontally-polarized E-field.

|

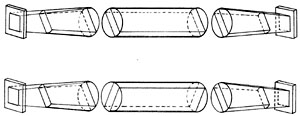

Now please take a look at the descriptive schematic drawings shown on the left in order to get an idea of how the frequency shift of 1,000 Hz might be possible. An incoming signal forms two polarized signals that are orthogonal to one another as it passes through the first end section, with the length and characteristics of its block having been chosen such that the signal that is parallel to the block is relatively delayed by a quarter wavelength - so let's call it a quarter-wave section. Then when that combination of signals passes through the center section, those portions of each signal that are parallel to the center section's block are delayed by a half wavelength relative to the other portions of either orthogonal signal - so let's call the center section a half-wave section. Finally, as all of that passes through the other end section (e.g., whose block is identical and set parallel to the block in the first end section), the outgoing signal is put back together in a coherent manner - but with its relative phase shifted by twice the number of degrees that the center section is rotated from a base position (i.e., perhaps as depicted in the view on the top - whereat all three blocks are parallel).

OK, so let's test the above starting with the top drawing. With all of the blocks parallel to one another, the wave front that is parallel to the blocks is actually delayed by a full wavelength but exits in a basically indistinguishable manner from the one that preceded it, whereby we can use that as a base zero phase shifted reference. Then with the half-wave section rotated by 90 degrees as shown in the bottom drawing, all of the wave fronts are delayed by a half wavelength or 180 degrees. You can test this further with other center section rotation values, but trust me - it works! Thus you can see that if one could rotate the center section at 500 revolutions per second, a frequency shift of 1,000 Hz would be generated.

In any case, Keith's suggested waveguide circuit comprised two branches of waveguide as implemented by directional couplers such as shown in the above schematic drawings - where the drawing on the right illustrates the method by which such directional couplers are in fact, directional. As you can see, the holes are spaced at nominal quarter wave intervals, whereby wavelets progressing in the forward direction simply pass through but wavelets in the reverse direction are spaced a half wave apart and cancel one another. In Keith's suggested circuit a first one of the two directional couplers was used to create the second branch, while the other was used to eventually bring the two branches back together again. And of course, both branches were powered by a single source so they were frequency wise coherent (e.g., except for the 1,000 Hz frequency shift of course).

The motorized phase shifter was disposed in one branch and an attenuator to be tested in the other. Then with the center section of the phase shifter turning at 500 revolutions per second, the frequency in its branch was either increased or decreased by 1,000 Hz depending upon which direction the center section was turning - whereby a crystal detector placed at the output of the second directional coupler sent a 1,000 Hz signal (e.g., to a receiver) whose amplitude was proportional to the strength of the RF signal coming from the attenuator on test.

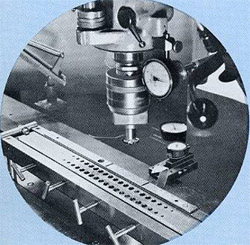

Of course, the above shown directional coupler schematic drawings are simplistic in nature. This is because the hole arrays are finite in length and have a beginning and an end. Thus Frank Barnett's directional coupler design included a graduation of hole diameters at each end of the arrays. Why there were two rows of holes instead of one row down the center I don't pretend to know, but assume that Frank was after a selected mix of electric field and current coupling.

|

In any case, those holes had to be precise in both diameter and location so forming them was definitely a non-trivial task, as you can appreciate by studying the Bridgeport milling machine set up shown to the left.