HP Memories

Here is an interesting question. If Microwave Engineer Art Fong had decided to turn down Bill Hewlett's job offer back in 1945, how would the Hewlett Packard product line of microwave signal generators, bridges, and a long line of spectrum analyzers be different today? We think those resulting product lines of today would be substantially different, because Art Fong brought a creativity and completeness to his vision of his products that really did affect those product lines decades into the future. Certainly Art's actual products themselves meant several hundred million dollars of revenues in their lifetimes, but the generations of ongoing products which he conceived, put HP into a sales pre-eminence they would never had if Art told Bill, sorry, no. This is his story.

My Life and Times

Art Fong

ForewordMr. Microwave, Art Fong

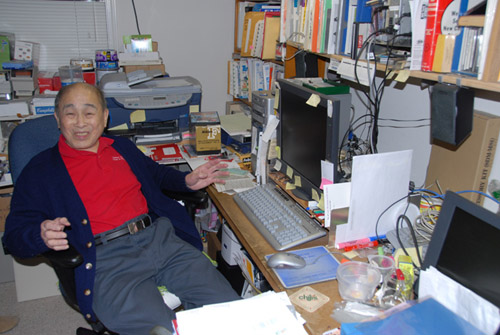

This title rests comfortably on the shoulders of a determined man, with the sparkling eyes of youth, a healthy humor, a self-effacing demeanor, and a long record of accomplishments. What else can you say about a man who has dominated the engineering of microwave test equipment for more than 65 years? An amazing, creative, and successful career, which first helped us win the technology battles of WWII and then at HP has produced a long line of better microwave products for our technology and communication world. Art Fong was one of the pre-eminent Asian Americans to find his calling in WWII high tech, at a time when the world was at war, and every element of the American scientific community was in an all-out effort to exploit our best technologies for military systems. His creative output at the renowned MIT Radiation Lab is not so well known, although his career in his decades at Hewlett Packard gave HP significant revenues which helped enormously in their stellar growth in the mid-20 th Century. You can't design and manufacture a radar system, or anything else electronic, without test equipment. So as those intrepid Rad Lab radar design teams raced time to roll out new radar systems to our military, the men in Frank Gaffney's Group 55 test equipment organization also had their racing shoes on. It was a little like the well-discussed HP "Next Bench" syndrome, where one instrument project would feed off another, at the next bench. For example, at the Rad Lab, Art used the small klystron tube, intended as a single-frequency radar local oscillator, to build a general purpose signal generator that could tune almost an octave. Or they would share the fast pulse circuits of the radar timing system to build better test equipment, like oscilloscopes, to test those very same fast pulse circuits in the radar. Art's career at HP is legendary. From a long list of signal generators across the microwave spectrum to the blockbuster HP 8551A spectrum analyzer, Art's project leadership was unparalleled in microwave test equipment annals. He was a mentor to several generations of brand new EEs, much like he joined MIT as a newly minted EE in 1943. His engineering style was always helpful, his vision, clear and concise. I still remember Art, when asked a typical uninformed marketing question by me, would pull out pencil and paper and in a VERY small script and diagrams, lead me to the right answer for a customer. At 92, he still exudes the confidence of a very successful engineer, knowing that his career meant something to humanity. He has every right to savor that feeling. (Sadly, Art Fong died on May 17, 2012. Some remarks from his memorial service at the Agilent auditorium on June 8, are filed in this archive.) His HP Memory is the stuff of fun reading. How about having your honeymoon trip be the railroad trip back to Boston to start his first big time job at the Rad Lab? After Art’s Memoir was published, Chuck House expanded on some contributions Art made at YHP, which had global implications to the semiconductor industry. They are included at the end of this work.

John Minck

|

|

My Early Years

I was born in Sacramento, CA, the son of Chinese immigrants. My father owned a grocery-store, and expected me to follow in his footsteps and to enlarge the family business. But my personality had other plans, which should have given my parents some clue to my ambitions and life-long stubbornness. But I should also observe that it's no surprise that I turned out an inventor. After all, I was born on Feb. 11, 1920, and Feb 11 was Thomas Edison's birthday too.

I recall that my love affair with engineering began in childhood with a block of wood, a sail, and an insatiable curiosity. I remember playing in the rainwater, and experimenting with handmade sailboats. But they kept tipping over, leading me to wonder why. After consulting library books and learning about a keel, I put a nail in the ship's bottom. It sailed beautifully.

That fascination with a toy boat launched me into a lifetime of inquisitiveness, as an innovator at Hewlett-Packard Company whose inventions generated nearly 30 percent of the company's revenues at one point; a participant in some of the world's most historic events; and a community-minded philanthropist.

But engineering was my natural talent, although in high school, inexplicably, I had no plans to attend college. My family had moved to Los Angeles in 1935 and all of us kids were expected to work in the family store. I thought that I could help expand the small store into a supermarket size. I was a serious student and studied hard. Although I didn't have many hobbies, I picked up some interest in Ham radio from the owner of a radio repair shop. I also had some interest in astronomy. Fortunately, a high-school teacher applied to UCLA for me, I guess because he was pretty convinced of my college potential.

Recall that this was still Depression time, and UCLA had just opened in 1934, at that time it was more of a 2-year Junior College, with a full degree in only a Liberal Arts field. I entered UCLA in 1937. At the conclusion of those two years, my family was not able to support my transfer to UC Berkeley, so I found a job at the Los Angeles Power and Light Company.

Los Angeles Power & Light, 1937 to 1939

In those years, LAPL was busy acquiring other local power companies. But inexplicably some of those generation and distribution facilities were running on 50 Hertz power. Completely incompatible with the standard 60 Hertz standard. So they were desperately in need of many technicians to convert equipment such as the home power metering installation, and to perform calibrations to bring it to legal status. I worked there for 2-3 years, making as I recall $100 dollars a month. I carefully saved as much as I could to allow me to then enter UC Berkeley, where tuition was just $54 per year and about $50 for books and fees.

UCLA and UC Berkeley

I started my college years at the University of California at Los Angeles, UCLA in 1939. I don't recall a very large minority percentage at Berkeley, there was no serious discrimination, but there were several professors who only had MS degrees. There were no minority professors that I can remember. But this was the time that the country was beginning to face the possibilities of world war. In the 1941 period, military recruiters were visiting campuses to look for technical candidates to fill the expanding research laboratories of the country. Quite a few men could see the future conflict coming and decided to sign up for duty, which resulted in a serious reduction of the percentage of men on campus.

I knew of Mary Ong, and had seen her about campus, but she was a very popular girl, and nothing came of my interest for some time. But then as more men left school, I began to see her informally, and a romance developed around 1942. Meantime I was taking up to 23 units to accelerate my graduation. In 1942, my junior year at UC, Dr. Lawrence Marshall came to Berkeley to recruit for the Rad Lab. Marshall was then working for the National Defense Research Committee. He was going around the country to top colleges looking for the top students to come to work for MIT Rad Lab. He couldn't tell us very much about the Lab, except that I would of course need a security clearance, it was a government laboratory run by MIT, and after that I would be able to go to work.

Dr. Fred Terman had also come by UCB to interview. He had been selected by President Roosevelt to manage the Harvard Radio Research Lab (RRL), for work on Electronic Countermeasures. He also talked to me. When he found out that Larry Marshall had already talked to me, he said, "I guess Larry Marshall has first dibs on you." Then it turned out later in life I got to know Dr. Terman much better while at HP, than I did Dr. Marshall.

I graduated from the University of California at Berkeley in February of 1943 and came to the MIT Rad Lab almost immediately. Mary and I decided to get married before we travelled to Boston. We didn't stay around for the graduation ceremony. I took my new bride across country on a train trip "honeymoon," and ended up in Boston. We stayed at the Gardiner Hotel and I walked across the Charles River Bridge to MIT and saw Dr. Loomis.

In our interview, he asked what experience I had? Luckily, I had done some work on high-speed oscilloscopes while I was at Cal-Berkeley. I also worked for three years at the Los Angeles Power & Light in their test labs. He noted that they didn't have many people in the test area, and that he would like to have me join his test equipment group. That was Group 55, headed by Frank Gaffney. It was a fairly new group actually. As it often happens in life, it turned out that that decision put me on a life path of designing test equipment for the rest of my 50-year career.

Meantime I was having problems with my draft board. The war was on, and they were after me all the time. The solution was that each time the draft notice came, I needed to send the draft notice to the NDRC (National Defense Research Committee) office in Washington to get it reclassified into 3-F, which was a kind of miscellaneous classification. I also had an ace in the hole, which was if I had been in real trouble with the draft board (some of them were pretty tough), the Rad Lab would arrange to get me a temporary commission in the Navy as an ensign in the Navy Reserve to keep me at the Rad Lab. But we never had to go that route. It turns out that each time I was reclassified 1-A, the 3F notice came right back. That continued while I was at Rad Lab too.

While I was in school, I would send my draft notices to the NDRC, and they would take care of it. In fact, one time while I was at Rad Lab, I'd gotten the notice in and somehow or other it was delayed and I did have to report for induction and take the physical at the US Armory down on Commonwealth Avenue. But before they could do anything else, the deferment papers came through, and I was all set again. That in itself is another story, but I don't think I want to go into the grim details of that Army Induction Center.

Those were perilous times. No one could tell just how our war effort would go. We had sustained some serious setbacks militarily, and people worried. Students worried, should I enlist, or get my degree so I will be more useful to the war effort? In those days of course it was an entirely different environment. We had been attacked by Japan, and the U.S. was very close to France and England, which were being beaten for the time by the Germans. I think most citizens supported the war effort, because of the Japanese vicious attack on Pearl Harbor. There was no question about it. There were very few protests if any at all. In fact, you didn't even hear about it at all. The mood was completely different.

Well, here I was, a brand new graduate engineer, I was personally very excited about my new work, because I did learn that we'd be working with very high frequencies. In those days, the curriculum at UC-Berkeley did not include very high frequency work; which was true of most colleges. The word "microwave" was kind of a hush-hush word in those days. It definitely wasn't being taught at most universities. The term "radar" had been mentioned in the newspapers, there was some reference to it, but that was about all. No one ever gave a description as to what kind of things that it would be used for.

I went to work at the Rad Lab in March of 1943, to begin a VERY challenging and interesting part of my young life.

|

This SCR-584 fire control radar for artillery was deployed in vast quantities |

As World War II was beginning in Europe, even before Pearl Harbor, President Roosevelt and his scientific advisor, Vannevar Bush, decided that the U.S. must organize quickly to concentrate our nation's science resources to prepare for a technology war. This was not a trivial decision because the nation was still rather strongly isolationist. They decided to locate one of the radar laboratories at one of the country's preeminent technology universities, MIT, at Cambridge, MA. Dr. Lee DuBridge was selected as Rad Lab Director. Since its objectives were to deal with radar the name "Radiation" became a descriptive title but for the general public the word tended to hide what was really going on there. It was opened in Oct, 1940 and operated until Dec, 1945. The output of scientific development there was just stunning in those few short years of maximum war effort. We developed most of the radars of WWII.

There was a complementary scientific lab established at Harvard, to research and develop Electronic Countermeasures, and our Fred Terman from Stanford was appointed to head that Lab. I got to know Fred really well in the years after I joined HP, when he was a member of our HP Board of Directors. The RRL used the deceptive title of Radio Research Lab, and operated from 1941 to 1945. Many of the country's scientific communities and most universities were enlisted to perform wartime research. We all know of the massive Manhattan Project which developed the atom bomb in 3 short years. The University of Chicago and the University of California at Berkeley were directly involved, along with Los Alamos and the huge uranium enrichment plant at Oakridge, Tennessee and the government operation at Hanford, WA.

One of the most vital developments of the entire war was the artillery proximity fuse which was created at the Johns Hopkins Applied Physics Lab in Baltimore. Other organizations like the Airborne Instruments Lab on Long Island were also active on military radios, radar and countermeasures projects, and were dismantled after the end of the war, or converted to civilian companies or Research Institutes.

|

Curator Note Around the time we were assisting Art Fong with his HP memoir, we became aware of a new book about a remarkable scientist in the 1920-40s. The book was called Tuxedo Park, a fascinating story about Alfred Loomis, born into privilege in New York, who made his fortune on Wall Street. He founded a private scientific lab 50 miles north of New York because science was his avocation. Loomis was a key organizer of the MIT Radiation Lab at the beginning of WWII. When we asked Art if he knew Loomis, Art recalled that on the day he arrived at MIT, Loomis was there to welcome him to the new job. Loomis suggested that Art work in Frank Gaffney’s Group 55, for test instrumentation. Imagine if Art had instead gone to work in a Radar System Design Group? He might well have later gone to work at Bell Labs, Whippany, GE or Westinghouse, and not HP. Such are the coincidences of life. When the decision was made to create the Rad Lab at MIT, Loomis put up some of his private funding to bridge the construction gap until government funding could be authorized. Click here to read the Tuxedo Park book report, by John Minck. It describes more details on the crucial role that Loomis played in WWII radar and also the Manhattan Project for the atom bomb. |

My work at the Rad Lab

Looking back now, I remember with fondness those challenging years, when I was a young engineer right out of college and joining MIT Rad Lab. What a remarkable transition to work among all the brains that were there (although I was selected as the top student in my class). But you can imagine what it was like being there with the best people in engineering and science in the USA and the world. That's really quite an environment. Anyone would feel a little intimidated, and I certainly was.

When I arrived at MIT, I reported to Frank Gaffney, who was supervisor at Group 55, whose lab worked on test and measurements, located in building 20/22. His lab did research and development on oscilloscopes, signal generators, spectrum analyzers, network analyzers, power detectors mounts and other wave-guide components.

The organizing message at the Labs was to "get the job done fast." We had a keen sense of urgency because our men were fighting and dying on all fronts, and our system technologies were critically needed to provide the important edge in surveillance and fire control radars from airborne to Sea Search to Army artillery.

The overall Rad Lab radar mission was to exploit the invention of the high power transmitting tube called a Magnetron, which was invented in England at the beginning of the war. The U.S. was able to improve that important invention significantly and make it highly manufacturable. The magnetron gave us the microwave illumination power we needed for any radar.

For the opposite side of radar, the Labs needed to invent a microwave receiver capable of detecting those extremely tiny reflections from the targets. While similar to your regular AM radio receiver, which tunes to 1 MHz, this one had to operate at 10,000 MHz. So we needed another significant invention of what we called a local oscillator. In your radio it is just a normal vacuum tube. Fortunately just a few years before, the Varian brothers at Stanford had invented a microwave tube they called a klystron.

The very first thing they had me work on was a high-speed oscilloscope. At the time such scopes were called a synchroscope. It tested the circuits that were designed for the pulsing of the transmitter and synchronizing the receiver. There were no commercial oscilloscopes. The idea was to perfect a highly stable triggered sweep. The typical pulse widths of that day were half of a microsecond to a microsecond long. That wasn't short by today's standards. But the techniques were such that test equipment wasn't very available. They did have an oscilloscope that was already partially designed, meaning it did not work as intended. Since I was low man on the totem pole, I was told to fix it, so I started to work.

I took over the whole project, just me plus a technician. I have forgotten the nomenclature of that box now, but I do remember that we used the name Q-scope; Q not meaning anything. It was a code word for that oscilloscope. It was capable of looking at modulated pulses, looking at a detected radar pulse to see what the pulse looked like. Being new, I had to learn about circuits and had to go to other people outside the group. I knew maybe ten of the people in that area in our group. In fact, they had come late in 1941 and '43, at just about the time when the Lab realized that they were going to need some pretty sophisticated test equipment, probably just as sophisticated as the radar itself.

I remember I had to redesign the sweep circuit, which was the very fast part of a circuit. I learned that a Dr. Britton Chance had quite a bit of know-how in that area, so I went down to see him. My first meeting with him was quite an experience because I was just a young engineer out of college, and here was a famous man, Dr. Chance, who was a group leader. He welcomed me into his office, which was only a bench with all the wires hanging all over. It was intimidating in a way to walk in there. There were Ph.D.s all over the Lab, and I was one of the few who was not a Ph.D. I did realize they were really looking for people with engineering backgrounds who could make things work, and that's the reason why they hired me. Dr. Chance was a real nice person. He put me at ease, and we spoke about some of his advanced circuits.

I went back and worked on the scope. I designed the circuit which gave it a very, very linear sweep in a very short time interval. It consisted of an RLC network. There were little complications in optimizing the linearity to near 100 percent. In fact, that was my first patent. That was quite exciting for a young engineer. I gave a lot of credit to Dr. Chance for steering me along. In fact, I just saw him in recent years. I talked about our Rad Lab conversation but he didn't recall it. But he appreciated my thoughts. He said so many things happened during the war that he couldn't remember all the conversations.

At the Rad Lab, communications were very informal. You could walk into anybody's office and start talking with them. There was no such thing as making an appointment with somebody. No one ever thought about that. It seems that most everybody was at work all the time, except when they were traveling. Most people were willing to stop for a moment and chat with you. So it made for a very informal atmosphere.

Considering the speed that we were developing our technologies, it is surprising that very little communications were going on between groups, in the form of seminars or briefings. We did have our own group reviews, which had to do with the projects, and they did talk about projects with the rest of the group. For instance, I would talk about the Q-oscilloscope.

We were talking to Freddie Jones, who was our group recorder. One of things we avoided was mentioning transmitted frequency or pulse rates. I guess this was for security reasons. I guess that was one of the problems that we had trying to communicate with everybody, because everything we did was classified. We never had a chance to talk to anyone. It was certainly unknown to talk to outsiders or vendors on anything that dealt with frequency or time.

Prototypes to Production

Our basic strategy was for the Labs to do the designing and proof testing for a new test equipment item, and then turn the design package over to an outside manufacturer for quantity production. Those manufacturers would use our drawings and take our specs and essentially just make copies of it. We really couldn't tell them anything about how the circuitries were developed and what it was going to be used for. So they were all in the dark. I don't recall the manufacturer for the Q-scope. It was somebody down in the New York area. One of my instruments was called TS-146, which was a signal generator and test set for X-band, and was built by a company called Air Radio down in Stamford, Connecticut. They made many MIT Rad Lab designs for military use.

Our normal process was to manufacture a prototype, maybe five or six or seven. Sometimes we might make as many as ten. These were given field trials, by the Army or Navy. They'd take them out and actually try them. NRL (Navy Research Lab) tested many. Then they would make suggestions for modifications and improvements. I guess they were our best sounding board as to how the stuff worked. After that was done, we called in a manufacturer. I don't know how the process was in the selection of a manufacturer, but we were told to work with such and such a company, and then we'd work with them. They'd come into the Lab, and we would go through the drawings. Then we would go down to the manufacturers themselves. Normally we go to them after they'd gone a little ways so that we could test their first ones off the production line and see how well they worked compared to the original prototype. First they'd always get a prototype so they could compare and see how things work and respond to each other.

Our design criteria was to produce test equipment that would stand the rigors of a military environment. Although my first signal generator was strictly for laboratory use, it would never be able to be used out in the field. My second version was in a dunk-proof box, and it had waterproof seals around it so it could, in effect, survive a dunk if it were taken out to sea and somehow got into salt water. All the transformers had to be covered so that moisture doesn't ruin it. They might tell us that the equipment must work at let's say, at 15,000 feet altitude. Of course, we would conclude it was going to be flown. But they wouldn't come out directly and tell us those things were going to be flown in a bomber.

Although our designs were almost always transferred to a commercial manufacturer, at the time there was no industrial effort in developing high-speed scopes. But in some other area, say, in microwave generation, where industry was conducting a parallel effort, there was more interaction, more cooperation in terms of design.

I would have thought that some of the other instruments would have more cooperation. But in the signal generator area we didn't have that kind of interaction. The components we chose were normally off-the-shelf components. For instance, the signal sources that we used were normally sources like local oscillators, and klystrons of the so-called Pierce-Shepherd tubes. The two of them developed the 723 klystron, which was used extensively throughout the war. John Pierce later went to Bell Labs, and then retired Stanford. I saw him there a few years ago and saw recently where he had died.

Our priorities were set for us by the project speed of the radar systems. As we were getting close to the time when it became operational, somebody would decide that it would have to have an oscilloscope or it would had to have a signal generator to maintain it, and we would be scurrying around trying to build something to test it.

Another instance, we needed a signal generator to test the radar receivers. The klystrons, which are used in every X-band radar for the local oscillator, seem like a likely choice. However these klystrons run over a fairly narrow range, and they offset from the radar frequencies by the IF frequency, which is 60 MHz or 30 MHz. We tried to operate those klystrons at the operational frequency of the radar. What I mean is we were trying to get a signal source that is at a radar frequency. But there really wasn't any particular klystron designed for that particular frequency. Now they're all fairly narrow band. We would go through a series of klystrons to find ones that might work at that particular offset frequency. This is considered dangerous practice, because tube manufacturers know that they don't have to pay ANY ATTENTION to performance of their tubes outside their specified use. Except, we were talking about getting something out in the field inside of six months.

Regarding the inputs for new projects. What generally happened was that the other system groups would come to Gaffney and request certain test gear. Then Gaffney would call us in and we'd sit down in a meeting with this particular group. Then we would decide what kind of a thing we needed. For instance, for a particular X-band radar, they wanted to be able to test BOTH the transmitter and the receiver with just one box. So we developed what we called a Test Set. It was ideal for field use because you only needed one piece of test equipment.

It had means for measuring transmit power, usually through a directional coupler that reduced the real output power. This power measuring device was the thermistor mount in a waveguide. Then you'd switch to the internal signal generator mode, to calibrate the sensitivity of the receiver. These are two different levels here. The sensitivity measurement may be down to -120 dBm, but the power sensing of the transmitter through a coupler may be 0 dBm. There's a huge difference in power. Normally, we would come out of this by means of a directional coupler, which gives a lot of attenuation. Of course we had the problem, too, at times, of somebody pushing the transmit button, and it would burn out the components the test set signal generators.

Our equipment was never intended for large scale production. They were intended mostly for field test for installation and maintenance. The first production run of the TS-147 was something like 500, and there were a few thousand of those made after the war. In fact, that one was made continuously after the war. There must be 10,000 of those out in the field. After going to Hewlett Packard, there were still calls for this type of a signal generator, but one with much more precision. At Hewlett Packard I designed a second-generation one, which did the same job with greater precision and a wider frequency range. See HP 624 below.

Quite a few other commercial manufacturers transitioned into post-war test equipment. Sperry Gyroscope did go into the microwave instrument business, and they manufactured waveguide components, signal generators, spectrum analyzers. Unfortunately, Sperry did not invest to stay in the business for a long time. From their viewpoint, this made sense because their main business was big Navy systems. They sold the waveguide line to Varian, who later sold it to HP.

HP on the West Coast didn't participate in any of these contracts during the war. Most of the microwave contracts were with Sperry. HP at the time did really low frequency oscillator type of equipment. So their expertise was at lower frequencies. That was why Bill Hewlett, who spent time in the US Army Signal Corps, recognized the opportunities in the microwave area. He came to MIT and asked me to join HP and do microwave design for them. That's how HP got launched into the microwave business.

During the war, we still obtained patents, but there was never much consideration about the legal aspects of them. In those days there were a lot of instances where people were using other people's patents, and no one really thought of suing the other person for using it. It was the same as a friendly handshake. Okay, fine. If you want to use this, it's okay. Let's have a little royalty or an exchange of patents. There wasn't really that adversarial environment. Nowadays, look at the software business. They sue each other just because it's something that looks like theirs. But I think things were a lot freer in those days, and nobody really cared too much if the patent was being used. It's just that you feel I'm going to have something better coming out pretty soon anyway, and so go ahead and use it. I think things were a lot friendlier.

After the war we were developing these technologies, but during the war there were some things which we couldn't really talk about. For instance, the high linearity circuit that I was talking about, that's really not classified information anyway. It's a technique for RLC circuitry. It's patentable, but the patent wasn't really issued until after I left the Lab. As a matter of fact, we didn't want to let anybody know about the applications during that time. How to do that is a little different story. It involves how one gets this super linearity.

My only HP Contact

At my Rad Lab job, I became acquainted with HP through their local sales representative. His name was Rube Ryerson, and he was selling Hewlett Packard oscillators at the time. We purchased one of the audio oscillators. But I didn't get my HP job through Ryerson. But there was a Dr. Wyatt from Aircraft Radio in New Jersey. I forget exactly what projects we did with him, but they manufactured some items that we had developed in Group 55. When the Rad Lab was closing up, he offered me a job in New Jersey. New Jersey wasn't one place I really wanted to be. So I told him I'd really like to go back to California. I thought if I can't find a job out there, I'll go back to school.

Wyatt told me that if he couldn't convince me to move to New Jersey, he knew of a friend in California who would be very interested in me. The friend he knew was Bill Hewlett. Hewlett was an MIT graduate. He'd gone to Stanford but did graduate work at MIT. And Hewlett was in the Army Signal Corps. Which led to my HP interview and job offer. I was just so happy to go back there that I didn't even ask what my salary might be. I just thought it was a young company; HP would be a great opportunity, so I joined them.

Bill had told me that they thought about going into the signal generator business. They had already done that in the audio-video area. They wanted to go into the high frequency and up to microwave area. So they hired me, and they also hired another fellow from Harvard, from the Radio Research Lab whose name was Bruce Wholey. He was a Canadian engineer who went to school at Stanford and was recruited by Fred Terman to RRL. After WWII, Terman became Dean of Engineering at Stanford. I did not know Bruce until I went to Hewlett Packard. He arrived there just before me, and so the two of us were the microwave persons at Hewlett Packard's microwave division. Later, Bruce became the Manager of the microwave projects.

We would have to work directly with them. It turns out that there was a real shortage of engineers in industry at that time. Most of the people went off to war, and the few people left were older persons. Although in those days if you were over 30, they really didn't want you in the Army. Most of those people had been educated many years ago, and their technology was really not up-to-date. So we had to lead them along, and we were telling them as much as we could without divulging what its usage was. We'd have to tell them what frequencies they had to work at. We had to tell them about the pulse width. But you couldn't tell them really what applications this equipment was being used for. We worked directly with the manufacturers; there was no production engineering as now. We did our best to fill the gaps. The projects that I had inherited were not engineered properly for manufacturing. That is where I had to redesign to the best I know. I did learn a lot.

My Other Microwave Projects

My work was so interesting because it ended up involving so many different applications of microwave. Although my first project was a high-speed oscilloscope, called a "synchroscope," I designed various signal generators; thermistor power sensor; attenuators; and a significantly-improved spectrum analyzers. I also designed a number of microwave components as needed, loads, detectors, etc.

On the thermistor project, when I arrived at Rad Lab, they did have X-band power meters, which had to be tuned individually for the frequency range of their operation. You would have a sensing element like a thermistor that absorbed the microwave energy coming down a waveguide. But it had to tuned for maximum accuracy, and that frequency range is fairly narrow, something in the area of maybe 100 MHz to 300 MHz wide in the X-band.

I saw the need for a wide-band thermistor mount that would cover, let's say, the 600 MHz range without the user making adjustments. So I took time out to develop that. In fact, that thermistor mount is featured in the Rad Lab series book, and the drawings in it were my original hand drawings. I'm a little disappointed that my name was never even mentioned in that book. But I guess that happened a lot. Contributions just never get reported on individual items. After Rad Lab, while at HP, I did design several similar thermistor sensors, which covered the entire X-band, 8-11 GHz, and a coaxial sensor. These are both described in later pages under Miscellaneous Components.

Training and Seminars

Although there was serious secrecy in our work, and logically so, there was still considered to be advantages to be had if we had some cross-communications on some of the technologies. These took the form of "Monday Night Seminars." They were on fairly selected topics, which were useful to the staff members in general. There were certain specific areas. For instance, if a new magnetron came along, then they would talk about it. Everything was pretty confidential.

I was clearly interested in what the other groups were doing, just from a professional standpoint, but also to gain the knowledge of the newest technologies. I remember one seminar. There was this guy behind me. My coat hung on the back of my chair like this, and he was smoking a smelly cigar. Every once in a while the ashes would drop off on the top of my coat. I was a little annoyed at the time. I turned around and gave him a couple of nasty looks, but it didn't seem to bother him at all. I found out later that he was Dr. Rabi. Someone else who attended mentioned his smelly cigar last night. When I found out he won the Nobel Prize, I forgave him.

At that time almost no colleges taught microwaves. MIT recognized that, and the first thing they did was send us up to a radar school that was given by the Navy, at downtown Boston in the Harvard Building. It was for seven weeks, 8 to 9 hours a day. It was held at The Harvard Building downtown in Boston, near the Winter Subway Station.

Classes were very intensive. They went all through microwaves and pulse formula techniques. They described to us what radar was, how it can be used for detecting, resolution and pulse width, how far it can go, timing, and things like that. In fact, everyone who came to Rad Lab attended that school. I often thought these all day classes were like getting a MS degree from MIT Radiation Lab on microwave technology and I got paid for the learning.

One other aspect of my first technology job was the engineering culture (EE's) versus the science culture (physicists). A fellow who sat next to me was a physicist, a very fast learner. His name was John Severinghaus, and he majored in physics. But he was a very practical person to begin with. Not the very, very highly theoretical person like some of them. But immediately after the war was over he contacted the University of Wisconsin and got an M.D. degree. He ended up at the UC San Francisco med center. He's doing research in bioelectronics. I'm sure that his work with electronics at MIT steered him into the field of bioelectronics. They're doing the same type of work right now, studying the human brain, trying to study how the human brain lives and why it dies so rapidly when it loses oxygen. It doesn't take very long. 20 minutes after it's deprived of oxygen, it's gone. So they're trying to study the effect so they can come up with something to protect the human brain.

Moonlighting at Browning Labs

After D-Day and Nagasaki, I did some work for part of the year for a company called Browning Labs. Browning Labs was another vendor that built a K-band test set for Rad Lab. I was not on that design team to start. Part way through I took over the project and brought it into production. These were signal generators in the 25 GHz range. That was the first attempt by Rad Lab to get into the millimeter area. We were just starting to get radars in that frequency, so we didn't get into full production in that particular area. While visiting Browning, I discovered that they made amateur radios. They made a commercial tuner for FM reception.

Experimental bands for FM broadcast in the range of 40 to 50 MHz were in use at the time. But during the war the commercialization of that band was stopped completely. The FCC decided to change the frequency of the FM band to 88 to 108 MHz, which remains today. Browning Labs saw the opportunity to do a lot of business in that area. So they asked me if I would "moonlight" to design the AM/FM tuner for them. So, during the last few months when I was writing reports and things like that at Rad Lab I was putting in time there. On weekends and evenings I was working on the AM/FM tuners, which turned out to be the first commercial AM/FM tuner and receiver of that era.

Personal Radiation

One of my most impressionable memories of The Labs was some immense commotion one day, when several scientists discovered how to operate high power magnetrons without filament power. Their new tube used the primary bombardment of electrons to liberate secondary emissions, which then heated the cathode. Everyone came to see this brightly lit object in the middle of a room. It was very warm even at distances of several meters, because of the thermal and microwave radiation.

Every person who viewed this miracle must have been thoroughly radiated and yet survived all this radiation. My lab was located a floor above all this radiation. Many people, including me, in those immediate space were totally exposed. Who started all this hysteria, blaming microwave or r-f radiation for many of today's ills? We didn't see a rush of premature exits of former MIT Rad Lab staff members.

The HP Interview

In 1946, with the war over, many Rad Lab personnel left immediately to resume their normal lives. Some of the staff remained to document the remarkable technologies that we had achieved during those several years of all-out efforts. By the way, the Rad Lab decision was to publish a bookshelf full of the WWII microwave technologies, from transmission tubes to the servo mechanisms which directed the radar antennas towards the threat airplanes. As the war was over, I assisted in writing some of the technical content of the Rad Lab book on instrumentation. I thought it was strange that the publishers decided NOT to include any names of the inventors and designers of these many technology breakthroughs. No credit for all that hard work.

It was interesting that contrarily, the RRL lab at Harvard made the decision NOT to publish their wartime work, and I am assuming that was because their Electronic Warfare technology was far too critical for the emerging Cold War with the Russians. (There was one report that I am aware of, which turned out to be one of three oral histories of Fred Terman, who, with his second in command, Oscar Villard, ran the RRL. The report is at the Green Library at Stanford.)

During Christmas 1945 we decided to fly home to LA and Pittsburg, CA, to show off our new baby. Airplane travel was very slow back in those days. In an old DC-2, I remember that it took 26 hours, and the flight must have stopped at 10 different airports. That gives some idea of the status of air transportation in the middle 1940s.

|

Bill Hewlett during WWII |

I was engaged in writing up specific information that I knew. My life took a new direction when I received a visit from William Hewlett, who was then in the Army Signal Corps and knew of my radar work. Bill's work at the Ft. Monmouth, NJ headquarters was closely connected to both the Rad Lab at MIT and Terman's RRL lab at Harvard. It was Bill's responsibility at the Signal Corps to pro-actively determine the technical needs of the military, which new radar capabilities were needed to defeat the enemy systems. So many of our country's military technology advances were due in a very high degree to the capabilities of Bill and his boss, James Macrae, to analyze those needs and feed them back to the scientists who would create the new systems. So Bill was a frequent traveler to Boston.

Bill had come to Boston and wanted to talk to me. He came over my house, Mary made a spaghetti dinner that night and Bill bounced my daughter Sheryl on his knees - he loved kids. We talked about microwaves and electronics all night. His work in the Signal Corps had involved some of my equipment. We talked back and forth, and at the end of the evening he offered me a job and asked how soon I could get to Palo Alto. Mary and I were delighted because we were both California natives and were serious about returning home - and I never had to look for a job!

It was interesting that in our long discussion that evening, it was mostly technical and we never talked about my salary. I was making $350 per month at MIT and I guess I just assumed that HP would match that. HP paid for the move of our household furnishings.

For our 1946 trip cross-country to my job at HP, I bought an old 1942 Buick and headed straight for "Highway 66" (remember that song?) to Los Angeles to visit my family. Then we soon arrived at HP on Dec 1, 1946. Once I got started at HP, salary was still never discussed until about 3 days before the first paycheck date. Then Frank Cavier, the finance manager came over to ask what my salary was going to be? I told him that Bill never stated it, so he went back to talk with Bill, and I was pleased that a few days later, my check was delivered, and it was $425 per month. A nice raise. A new job. Things were really looking good for me and my family.

I was the 6th R&D lab employee in the new post-war engineering dept at HP. Bill had also hired several other engineers from the Rad Lab and Terman's RRL, Bruce Wholey, and a few others. In any engineer's career, the life generally revolves around the instrument project being worked on for a period of 1-2 years, some as you will see are so large, like the spectrum analyzer, that more years are necessarily committed. So I will segment my remembrances by lab project.

Racial Palo Alto

In my long career in Silicon Valley, I had always hoped that it would be my skill in science and computers that drew attention, not my race. And yet, I was often reminded of my Asian heritage. It's a very strange thing, because in those early years, Asians seemed to have a difficult time everyplace. Other minorities like Jews, African-Americans, and Hispanics had similar problems. When we came to Palo Alto in 1946, we couldn't find a place to live because all of Palo Alto had restrictive covenants written in the land deeds, for Caucasians only. It was illegal for me - a Chinese American - to buy or rent a house in the desirable parts of Palo Alto. But I determined that wouldn't stop me from trying. About that time in the post-war politics, local and national anti-discrimination activities were brewing. Soon there was US law passed which legally removed those covenants on the land deeds, all at once.

I found an empty lot on Parkinson Avenue near the city limits of Palo Alto, which also happened to be part of a small development which didn't actually have any race restrictions. I did take some time to go around and interview the close neighbors to find out their feelings about diversity. In those years, Stanford was enrolling increasing numbers of International students who were seeking housing in the city. Interestingly, at that time, the well-known developer, Joe Eichler, was very active in South Palo Alto, and was busy getting those racial discriminatory clauses eliminated as unconstitutional.

I did build a 4 bedroom house at that site, and raised my four kids there. This area now has become a desirable area with the best schools, near the Main Library, Children's Library & Theater, the Community Center, Rinconada Park with tennis courts, swimming pools & playground and the Children's Museum.

My present home, built in 1992, is next door to the first; my garage workshop was made large enough to hold a large accumulation of instruments and life artifacts.

Working in the HP work culture

The early HP was quite similar to the well-known HP Way of dealing with employees and associates. It was a great environment. Both Bill and Dave were in the Lab several times a week. They were thoroughly involved in the projects. They suggested answers to problems and offered who to go to for help. In one instance, I was working late one evening testing a prototype for a trade show. Dave came in, sat down, and helped write data in my lab book. Have you ever found a boss like that?

One of my most memorable moments was with the company car, a Mercury station wagon. We were driving to an IEEE meeting up in San Francisco, with Bill driving, and we were all in the station wagon. We came up to Canada Road in the foothills, which was just being re-built, and they had not put the pavement in yet. There were all sorts of holes and ruts. And Bill says, "Let's see now, there must be a speed where I can just hit the tops of the bumps and it would be a smooth ride." We went all the way from 50 to 100mph. Bill was a reckless driver! We never did find that critical speed.

The Police Radar Project, circa 1947

Before talking about my regular instrument projects, I will describe one of my more interesting innovations, which was my contribution to police radar technology. While we were at MIT Labs we had talked about a police radar with various people, but nobody had built one. I got to HP and one day I was up in San Francisco in one of those surplus stores. I saw all that surplus X-band gear up there, and for fun I bought a parabola and other supplies to build the radar concept on a bench.

One coffee break we all went outside and I wanted to show the radar. Hewlett even joined us for a bit and said, "That's real nice, Art... but we don't want to make something like that... we're in the instrument business." It was about twenty years later before the commercial police radar came out... of course they're a lot smaller. The one I made just helped prove that the idea was there.

|

Parking lot demo of the vehicle radar, Bill Hewlett on my left, with coffee |

Bill was asking questions and fiddling with the adjustments to understand how it worked. He had Ed Porter drive up and down Pepper Ave , while he was watching the meters. Pepper Ave in those days was unpaved, it was the street that ran from El Camino and dead ended at the HP Quonset building. The photographer was head of the sheet metal shop.

And, speaking of the Quonset building, I arrived at HP in 1946, the small engineering group was located in the back of the Redwood building. We soon moved to the Quonset building just behind. It was a pretty miserable place to work, I remember that Al Bagley had just been hired from Stanford. It was very HOT in summer and VERY COLD in winter, not much insulation on the metal construction.

I remember seeing Brunton Bauer, our lab manager, many times, trying to get warm, he had put his chair on top of his work bench, reading a magazine, etc., with his back toward the overhead vent. I had to pass by other people's office to get to mine on the end of the Quonset. It was next to the east end sliding doors; which made it even colder. In the summer it was too hot, but being near the outer door, I got more breeze.

|

The HP 650A Test Oscillator |

My first assignment at HP was the HP 650A Test Oscillator. I remember casually mentioning to Bill Hewlett that I had been hired to work on microwave instruments. But Bill just told me that HP needed this oscillator at this time, so I went ahead with it.

By this year, 12 years after its founding, HP boasted a line of test oscillators spawned by the original HP 200A which included, 200A/B/C/D/ H/I in addition to 201B, 202A/B/D, 204A, and 230/31A/32A/33A. Whew. Most of these were variations for audio, sub audio and supersonic.

But with the coming of TV in that decade, there was an increasing demand for a test oscillator covering the "video" range up to 10 MHz. We all remember the historical fact that Bill's original Wein bridge technology ran out of steam in the 50 kHz area. In those years, Bill Hewlett would visit Barney Oliver at Bell Labs, always trying to convince Barney to move to HP and Palo Alto. In those discussions, Barney pronounced that the simple technique of using a balanced circuit would yield a nice increase in top frequency of the HP 200CD to 600 kHz.

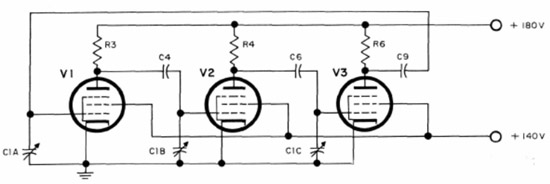

So when I set out to design the HP 650A, I determined right away that the simplest way to cover the entire 10 Hz to 10 MHz was to include two different oscillators. The low frequency one to 100 kHz was the traditional Hewlett Wein bridge. For the high frequency oscillator, I chose this block diagram as shown, which was suggested by Barney.

|

The high frequency oscillator used three stages of R-C phase shift |

It consisted of three phase-shift R-C stages in series, with tuning capacitors C1A/B/C and each stage contributing 60 degrees to the 180 needed for oscillation. The oscillator improved on the previous 200-series by building in power monitoring functions and a calibrated output attenuator in a 600 ohm environment. The HP 650A was an extremely popular instrument, filling a real need in circuit labs around the country.

It's not obvious from the diagrams, but since there were two different oscillators inside, and they needed to use the same tuning dial, this meant that we needed to spend quite a bit of time correlating the tuning curves of the Wein Bridge oscillator and the 3-stage oscillator. Since the parasitic capacitance of the 3-stage version factored into the tuning, it took us quite a bit of tweaking to make the tuning dial work for all ranges.

|

The HP 803A Impedance bridge, and HP 417A Tuned Receiver |

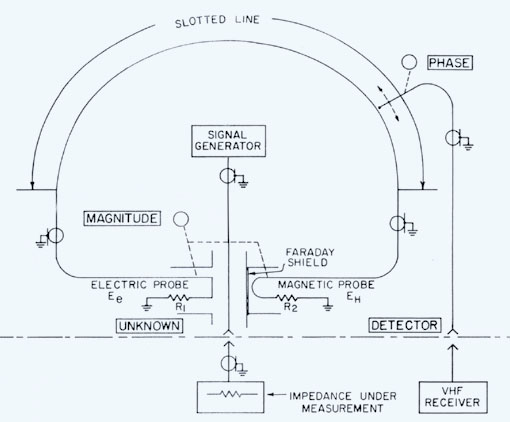

My second project at HP was the HP 803A Impedance bridge. This time was several decades before modern vector network analyzers, and circuit designers were always trying to characterize components which had to operate at RF frequencies from 10 to 500 MHz and above. Slotted lines were well known but didn't operate below 500 MHz, because they had to be too long. Regular resistance and capacitance bridges only went up to 10 MHz, in general.

So we decided to exploit a concept suggested by John F. Byrne of Airborne Instrument Lab, which could give us a very accurate measurement of impedance from 10 to 500 MHz, and extend with less accuracy to 5 to 700 MHz. It was a very clever idea to use a long slotted line which was curled into a circle to save space. The basic idea was to launch two signals into the two ends of the circular slotted line. One of the signals was picked off the reflection of the unknown component, using a magnetic loop. The other signal was picked off the reflection using an electrostatic probe (launching signals that are 90 degrees apart).

By clever mechanical adjustments, the magnetic and electric probes are moved in and out until the voltages they generate are equal, resulting in the ratio being equal to the amplitude of the unknown impedance. Likewise, the moving probe on the slotted line is adjusted around the circle until the two phase-signals are equal and the position of the probe then gives the phase of the unknown. The detector is a super-regenerative receiver, the HP 417A which tunes from 10 to 500 MHz with 5 µV sensitivity. Thanks to Norm Schrock for the help putting the receiver into production.

|

The HP 803A Impedance Bridge used the Byrne Bridge principle |

|

HP 809B Universal Probe Carriage, and 806B Coaxial Slotted Section |

Throughout my career at HP, most of my work was directed toward instrument products. But along the way, I often took time to design microwave measurement components which I found necessary to characterize some of the instruments I was working on. In this case, I needed a more precise way to measure SWR, so I took a little time to design the HP 806B coax slotted line.

The HP 809B carriage along with a number of waveguide slotted lines, which were all interchangeable, had been introduced a year or so before, as part of the HP purchase of some microwave technology from Varian Associates. But that did not include a coaxial line. Our main contribution for the coax line was to improve on the Type N connector specs. The Type N had been standardized during WWII, but the military dimensional specifications were too loose for a measurement piece of equipment. So we established tighter tolerances to minimize the allowable spacing on the interface of the center conductor.

|

The HP 624C Microwave test set |

As Hewlett Packard moved its product strategy into microwave products, in the post WWII period, we had some relatively good connections to the DOD Research community. Bill Hewlett although he was himself an Army officer, his job responsibilities also brought him in contact with U.S. Navy research programs.

As a result of this, plus the WWII experience of other research engineers who Bill hired from MIT and the Harvard RRL, such as Bruce Wholey and others, we were already positioned to create a line of signal generators which we could be quite sure would meet new military system requirements. In fact, the U.S. Naval Research Lab was one DOD Agency which would soon begin writing contracts to design new signal generators for higher and higher frequency bands, as their systems, both seaborne and airborne were rolled out to the military services.

Meantime, there were requirements to continue the production of a military-oriented test set, which I had already worked on at the Rad Lab. These model HP 623 and 624 Test Sets were quite easy to design because I had done much the same before. The requirement was to provide a signal generator function, with output from 0 to -100 dBm, utilizing narrow band but tunable klystrons made by Varian. These were also klystrons designed for radar system local oscillator service.

An input connector led to the radar system antenna port. With the transmitter off, the front panel selector switch sent the Test Set signal generator signal into the system receiver where it could check sensitivity and also provide a pulsed test signal to check out the pulse circuitry of the radar, even the displays.

Next the internal signal generator would be selectively switched into the Test Set's own power meter, which was a thermistor sensor, and detection circuitry, to set its power point accurately. Finally, the selector switch would open the power meter to the radar transmitter, which could measure average power up to the 2 mW point. Of course, it was critical that the really high power of the system transmitter be attenuated properly usually with a directional coupler, so it would not burn out the sensor. A tunable cavity wavemeter was inserted in the power sensor signal path, and it could be used with the power indicator to tune to a dip in power to provide 0.03% accuracy on frequency.

So, these completely self contained test sets were ideal for field calibrations and maintenance of radar systems. Later, as the ATT Bell Labs moved to install their 3.7 to 4.2 GHz TD-2 microwave links to cross the country for multiplex telephone trans-continent communications, the same test sets were adapted to somewhat different frequencies and for FM modulations instead of the radar type pulsing.

More Information |

The HP 616A Microwave Generator. Its front panel is

virtually identical to the HP 614A. |

The HP 614A and 616A were similar construction and circuitry. For a new Navy contract for 616A's, Bill Myers picked up a US Navy generator design, and commercialized it. I was designer of the HP 614A, which required considerable new design work because we used the same Klystron tube, but the oscillation modes were completely different for the lower frequency range.

When it came to designing signal generators for HP, that was my specialty, since I had designed several at the Rad Lab. HP's move into microwave test equipment came from a continuing demand for those frequency bands because our Defense Dept was continuing to develop new radars and countermeasures for new aerospace and defense systems. The Korean War had intervened and created new applications for advanced fighters and Navy systems.

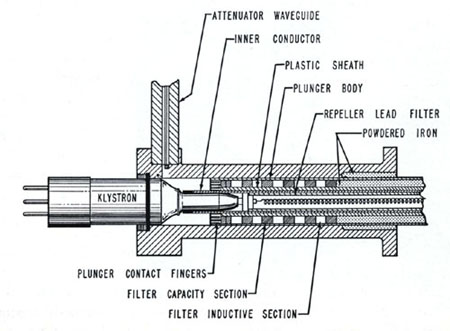

The signal generator technology had not advanced all that much by the early 1950s when Bill modified the Navy design on an S-band generator, which was to become the HP 616A. We still counted on using a reflex klystron for the signal source. A reflex klystron depends on the simple principle of accelerating a beam of electrons from a cathode, through two grids, and then as they approach a tube element called a reflector (repeller), the high negative charge there “reflects” the beam. Then they head back through those same two grids. When the entire assembly is encased in a frequency-dependent tuning cavity, the microwave resonance of the cavity concentrates energy as a resonant field, which tends to bunch the electron beam, taking energy out of the electron beam and converting it to microwave energy.

The cavity of the HP 614A was a coaxial configuration, easy to manufacture, and capable of metal finishing processes which are able to fabricate a moving short down the opposite end of the cavity from the klystron. HP manufacturing shops were able over time to really perfect the sliding fingers to provide a good short but still have long life for thousands of mechanical tuning cycles. So the main tuning function was to move the cavity short. But also recall that the oscillation process called for the repeller to bunch the electron beam, so as the frequency changed, it was necessary to change the amount of negative voltage on the repeller. Our generators all did this simply by ganging a potentiometer with the tuning shaft. The only complication to that was that often the repeller characteristic of a particular klystron model was not exactly linear, so we simply used warped tapers on the potentiometer. It meant that the technicians tweaking the arrangement for the first time had to know what they were doing.

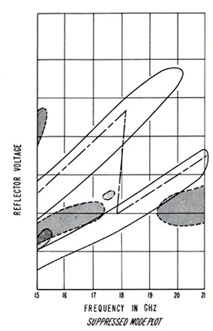

In the HP 614A cavity, there were many oscillation modes (see the example HP 620A mode diagram below), even with the same short setting. I came up with the idea of using a band pass coax filter arrangement, which was placed at the shorting end, which suppressed much of the troubling spurious modes.

After the cavity is up and resonating, we needed to get the microwave power to the outside world. This involved another “magical” quality of microwave transmission theory, which was called the waveguide-beyond-cutoff principle. Whenever a microwave signal is sent down a tiny hole, say 3 mm, although the number is more precise, that hole diameter is MUCH smaller than the signal’s half wavelength, which is 50 cm, at say 3000 MHz, the middle of our tuning range. In that case, there is a strict mathematical law which states that for every diameter that the signal moves down that cutoff guide, the signal attenuates at a rate of:

For this example, the radius would be 2.5 mm, so the attenuation would be 6.36 dB per mm, meaning that to achieve 127 dB power range, the probe would move 20 mm, about an inch. To extract power from this magical circular waveguide, we provide a sliding probe with a tiny loop on the end, which also contains a 50 ohm resistor. The gearing for the probe is very precise and has non-backlash gearing, connecting to the front panel control for output power. For a given generator we would design our attenuator control on the front panel to be geared for distance, but calibrated in -dB. The beauty of this kind of attenuator was that it provided extremely accurate signals down to -127 dBm, which was important for some receiver designs.

Now, all that remains in the power train is to measure and set the output power. The reason is that as the frequency changes, the klystron output power changes, so we arrange another moveable pickoff probe in an identical cutoff guide, which runs at high level and drives a thermistor detector for a typical 0 dBm reference level. We used interconnected gearing, so as the power output, say drops, in order to get back to the 0 dBm, the probe needs to be set closer to the cavity opening, and in doing so, out of the front panel, the cursor over the attenuator readout moves the amount to correct for dropping cavity power. Simple in concept, but a very tricky mechanical engineering project.

We also need to design pulse driving circuitry which can drive the klystron on for pulse widths like 1 microsecond, with a wide control of pulse rate, pulse width and pulse delay from a synchronizing pulse. These numbers all match the common radar system parameters. We can also design in FM modulation because if you apply an AC voltage to the negative repeller, you get relatively good linearity of FM signals, over perhaps 50 - 100 MHz.

At certain times we also signed military supply contracts to ruggedize the components and mechanical elements, supplied the signal generators in environmental transit cases for field use for very large quantities.

HP 620A Signal Generator, 7 - 11 GHz, circa 1954

Hewlett Packard Journal, Jan-Feb 1954

When you look at an HP/Agilent catalog, and page after page of klystron signal generators, you might logically think, "If you've designed one klystron generator, you've designed them all." They all look alike and the block diagrams are much the same. Not true. While I was able to leverage this X-band generator from work I did on the HP 616A, above, we had to deal with dimensions in the cavity design which were 3 times more difficult because the frequency band was 3 times higher.

There were some spurious modes to be contended with, but we were able to design a rather sophisticated mode suppression fix. It consisted of a cascade of high and low impedance filters inside the cavity, to prevent out of band oscillation, such as 6500 MHz which sucks out power even if it could be filtered out at the output. We also found that by using higher repeller modes, we could get better performance, but for this exceptional range we had to use two different repeller modes. This necessitated triggering a microswitch in mid-band to jump the repeller negative voltage to the next repeller mode at the proper point.

|

More Information |

Graph Showing Klystron |

Simplified cross-sectional view of resonator used in Model 620A |

|

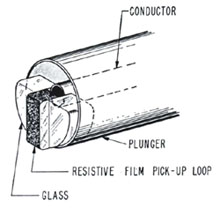

The HP 620A Attenuator Plunger Pick-up Loop

was less than 1/8-inch dia. |

Another mechanical challenge came up with the waveguide-beyond-cutoff attenuator. At these X-band frequencies, our usual calculations for the diameter of the attenuator probe would have to be only 1.6 mm, which would be only about 1/16th inch. Building such a miniscule structure with a coaxial line and pickup loop with 50 ohm resistor at the tip would be virtually impossible. So instead we went with a larger probe, about 1/8 th inch, still tiny but with care could be produced. The 50 ohm loop was made with thin film deposition on a glass bead, with machining to create a loop. Clever indeed.

I recall once long after the generator was selling, that a large military contract for the same generator was won by a low bidder, who got the manufacturing drawings from the procurement office of the service. What they didn't realize when they bid low was that inside that mechanical cavity assembly was some truly sophisticated fabrication. They called HP and asked for help on the processes they needed. I guess I have to say that we didn't feel all that bad in turning them down. Let them work it out with the procurement office, which would be no help of course.

More Information |

HP 606A |

The all-time winner in signal generator production is probably the HP 608-family. The A-model was introduced in 1950, and other models up to HP 608E/F shipped until replaced by the HP 8640 in 1972, a remarkable lifespan for a technology product. One reason was that its frequency range of 10 to 500 MHz covered a very large number of different AM communications applications from Police radio to military communications in many bands.

And yet, the HP 608 didn't do a very good job of covering the bottom part of its frequency range, so we made a decision to create the HP 606A. We were still in the vacuum tube technology era. But more important, a vacuum tube oscillator sustained larger voltages in the tuning circuits, so that the spectral purity of the output, ie., the ratio of carrier signal to single-sideband spurious signals was very high, on the order of 70 dB.

Over the years we had learned a lot about feedback control of generator output amplitudes, for customer convenience. We accomplished this, such that a user could merely tune for his desired frequency, and the output remained solidly and conveniently constant. But we carried the feedback stabilization onward to the amplitude modulation too. By using super linear detection, we were able to compare the input modulation signal (or internal modulation source) with the detected envelope signal and make them equal, so the modulation fidelity was outstanding.

Finally, we needed something other than a waveguide beyond cutoff attenuator, to set output power down to 0.1 µV, so we designed a novel switched resistive pad arrangement using pairs of common commercial micro-switches for each attenuator stage. Surprisingly, these worked just fine up to 65 MHz of the top tuning frequency. The microswitches were arranged in pairs and were activated by a cam-operated shaft, from the front panel.

More Information |

4 pairs of commercial micro-switches cut resistive pi-pads in and out of the through path |

|

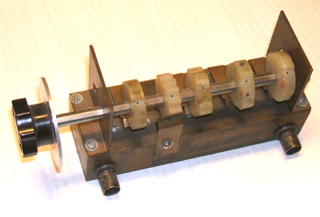

The 355 prototype was hogged out of solid brass |

The prototype had the components inside a brass cavity, machined for space. One of our mechanical engineers saw it and strongly suggested making the housing out of an aluminum die casting, which over the shipping life saved an enormous amount of machining. I still have the prototype in my shop at home.

Another interesting story. I had designed the coax attenuator for the 65 MHz signal generator and I knew it would work at higher frequencies. I didn't know how high though. We had this summer intern from Stanford, Harley Halverson, so I asked him to measure the frequency range. It went to over 200 MHz, and with one tweak it worked to 500 MHz! That got Harley going, and by using the new HP 185A sampling oscilloscope, he arranged a time-domain reflectometer to individually adjust some capacitance blades to get it working to 1000 MHz. Which we packaged and sold by the thousands as a separate component. Harley was an exceptional engineer.

I showed the attenuator to Noel Eldred, the first VP of Marketing and he looked at me and said, "We are not in the components business, you can't sell this." I sneaked it into a catalog and soon it was selling for more monetary volume than some other sig gens. Afterwards, Noel saw the sales revenue and profit and came to the lab to find me. He grabbed me by the shoulder from behind and said, "I'm glad you didn't listen to me!" The results were fantastic. The factory costs were about $25 and the selling price was $125. It's still in the 2005 Agilent catalog, selling for $1000.

More Information |

HP 851/8551 |

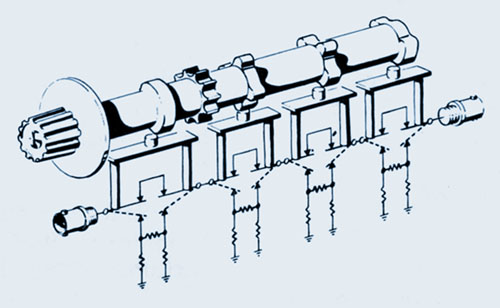

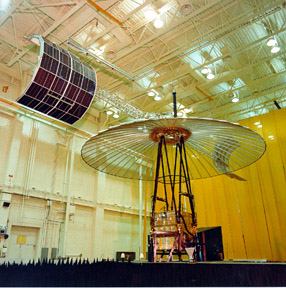

There is no doubt whatever that the most important project in my life -and the most successful- was the HP 8551A/851A microwave spectrum analyzer. Much has been written about this first entry for HP to get into the spectrum analyzer sector. We launched HP into Spectrum Analyzer market in 1964. This market was owned by Polarad and Panoramic Corp.

Both companies produced Analyzers which were mostly single-octave-band, hand-tunable receiver using klystrons as the first Local Oscillator. The second LO was the sweeping one, providing a 100 MHz sweep-width in the best case. But we took a big technology step by totally revolutionized this concept by assigning the sweeping function to the first LO. By designing a sweeping FIRST Local Oscillator, using a backward-wave-oscillator (BWO) for the source, it was possible to provide a remarkable 2000 MHz of sweep width.

The HP 8551A was presented for the first time in the August, 1964 issue of the Hewlett Packard Journal, and in the 1965 catalog under the following subtitle: "A Totally New Concept in Microwave Spectrum Analysis." It would be the first of a five decade, permanently growing leadership, which is still today a leading product line of the Agilent Technologies Company.

I "borrowed" the following content description of the 8551 project from John Minck's HP Narrative since it presents all the appropriate facts about this remarkable microwave tool. I should also note that early on we decided to split the instrument into a microwave section (8551A) and a display section (851A) because of packaging considerations. I also acknowledge the two groups, George Jung, led the display section and Harley Halverson was leader for the microwave section. They did a magnificent job.

The frequency-domain oscilloscope

As mentioned earlier, this product put HP into a brand new microwave market area. We had been known for signal generators, power meters and swept-frequency testing before that. But the market for spectrum analyzers was owned by Polarad with about $5 million annual revenue and Panoramic Corp., at about $2 million. Spectrum analyzers had been designed for use with radars during WWII, and Polarad, located in New York City, had been a contractor for the government. Basically, a spectrum analyzer is a tuned super-heterodyne radio, with a swept-frequency or "panoramic" display, signal power plotted vertically against a horizontal scale of frequency.

HP launched into spectrum analyzers, partly driven by pressure from our Field Sales Engineers, who were looking for a new market area. The Polarad analyzers were mostly single-octave-band, hand-tunable klystrons, used as the first local oscillator. The sweeping 2nd local oscillator (LO) provided the 100 MHz sweep width (dispersion, in the jargon of the day). The Panoramic Company, also on Long Island, was soon building a multi-band unit, capable of 2 to 12 GHz, which down-converted using harmonics of the 1 st LO.

The project engineer assigned to the HP analyzer was Art Fong, who had been recruited from the WWII MIT Radiation Lab. His experience there had involved building signal generators and specialized spectrum analyzers, including waveguide components. By designing a sweeping FIRST local oscillator, using a backward-wave-oscillator (BWO) for the source, it was possible to provide a remarkable 2000 MHz of sweep width. The key technology, needed in the use of the BWO, was the breakthrough use of a tracking, phase-locked, low-noise-VHF sweeping oscillator. The ability to track while phase-locked, quieted the phase-noise of the BWO tube, when in the narrow band sweep mode.

The HP unit was conceived to have a number of significantly higher-performance features, far wider sweeps, an honest and calibrated 60 dB of amplitude range. Yet, it was thus destined to cost much more. In my original market research, I had found that most customers would have been happy to have the same performance as Polarad, but just have a product brand from HP, with HP workmanship, features and reliability. But when we plotted the price-volume curves, the tail of the curve, as usual with most HP products, stretched flat, far to the right. Which simply meant that there would be considerable demand, even with prices that might be twice the available products, or in this case, some real demand even at $15,000.

The HP 8551A Spectrum Analyzer was first demonstrated, privately, to customers during the 1963 IEEE show in New York. Project Engineers Art Fong, George Jung (HP851 display), Harley Halverson (HP 8551 RF section), and others, had finished a prototype, to bring to a hotel room, for showing to VIP customers. The unit was mounted on a draped table, but under the drape was a massive fan, blowing air up through a laundry dryer hose umbilical, to keep the parts cool. It took a lot of air to cool the high-voltage power supply, needed to run the backward-wave-oscillator, requiring 2400 volts.

A lesson in pricing strategy

Actually, the price was approved in a hotel room, too, a year later, just prior to the 1964 New York IEEE show. Marketing V.P. Noel Eldred, Division Manager Bruce Wholey and I met to agree on the price. I presented a price-volume plot to guide us on the product price. Largely an estimate, it showed that at prices of $5K, where there were competitive offerings of less performance, the volume might be 50-100 per month. At $10K price, the volume had dropped to 20 per month, but the volume line went almost flat from that point out to $20-30K price, confirming that customers would pay a lot for our unique features.

Reflecting on Dave Packard's philosophy to price for value, Eldred didn't hesitate, and approved a price of $9500. Imagine our surprise when, within the first year of production, the volume went past 75 a month. It soon became HP's first $1 million-a-month product. An early lesson, I learned at that meeting, was that we continuously under-estimated the amount of money our engineer-customers were willing to pay for HP products, that have unique performance features.

It was Paul Ely's idea to position this product as a "Frequency-Domain-Oscilloscope." And it truly was just that, because it could sweep a baseband of 10 to 2000 MHz in a single display. This single instrument became the $10 million grandfather to HP's entire Signal Analysis Division, and taught many fledgling engineers and marketeers some powerful lessons on product strategy, positioning, and marketing.

The rest of the story

Here are my sales forecasts for the Spectrum Analyzer, from the 1965 MWD market plan binder, which I recently found in some old boxes at home. I think I made the forecast in late 1963.

| Year | ------ | Annual Sales ($M) |

| 1964 | 1.05 | |

| 1965 | 2.85 | |

| 1966 | 3.09 | |

| 1967 | 2.85 | |

| 1968 | 2.61 | |

| 1969 | 2.38 |

Realizing that the annual revenue in 1965, generated from 75-100 units per month, was between $8.5 and 11.4 million, the above sales forecast was woefully conservative. But, since the Microwave Division had been enduring a recession from 1962-64, with flat revenues of about $20 million, we were extra cautious. Yet, the HP 8551A was one good reason we emerged from that recession faster than normal in 1965.

We all knew that it would be a success, but it was one tough project. We were trying to design the first spectrum analyzer that would cover whole octaves - I think there was one experimental system which occupied a whole rack which did some of that function. The critical element was the local oscillator. We chose to use the Watkins Johnson BWO and it had spurious signals, which added those spurious to the display. Our engineers and theirs had a tough time finding a solution, because it had to be a smooth magnetic field. After thinking about it, I suggested placing small magnets over the outside of the cylindrical main magnet, to straighten the magnetic fields, and it worked! So all we needed was to find small magnets and glue them to the main magnet, while watching the spurious effects on the spectrum screen.

Market effects of the HP8551A