Discovering the Fundamentals of Hard-Copy Graphics

and Innovation Management;

The HP 7580 (Big Bertha) Story and What Happened Later

, by Marvin Patterson

ForewordMr. Large Format Plotter-Marv PattersonThis is a story about motivational leadership and technology dissemination in a globally-dispersed enterprise. It is also about organizing creativity and innovation-sharing which seemed to exist in the infant HP, 6 decades before. By the 1980s, HP had some 40 divisions, with stovepiped R&D, meaning random sharing of technology. Marv thought a lot about these principles as he progressed in his career-but first he had to gain experience in the design trenches and project leadership. His observation: "If HP only knew what HP knows, we'd be a much greater company" says it all. And it pinpoints the focus of centralized HP Corporate Engineering of the 1990s. But first, Marv's story. As Hewlett-Packard emerged from WWII, and embarked on a decades-long dominance of the measurements marketplace, many other companies were building measurement-associated products. The measurement data resulting from a variety of instruments needed to be recorded-and this was long before the advent of computers. The Brush Company of Cleveland built strip chart recorders with ink-pen styluses that plotted voltage vs time, in the WWII period. There are early 1950s pictures of Packard testing one of his instruments with a Brush strip-chart plotter. Post-war aerospace companies needed multi-channel strip charts for flight testing of airframes, sometimes requiring dozens or even hundreds of channels for a given highly-expensive flight. Reliability was crucial since all those measurements sometimes recorded catastrophic failures, which enabled analysis for improvements. Consolidated Electrodynamics of Pasadena built tiny "string" galvanometers, which deflected light beams to expose 20 or more channels of voltage traces on photographic film. Once the magnetic tape technology got rolling for audio reproduction, companies like Ampex added instrumentation channels for data recording. The Sanborn Company of Waltham, MA, was known for medical electro-cardiographs, plotting the well-known heart pulse waveforms. Their multi-channel medical recorders were soon repurposed for aerospace applications, bringing them into the general measurements field. In laboratory applications, there was a need for recording the relation between two voltages. Enter a small company in Pasadena, founded by Francis Moseley, was producing X-Y plotters. The X-axis and Y-axis each responded to separate voltages, and plotted the result. Usually the engineer would manually change one of the voltages and observe the display of the resulting change in the other voltage. Moseley introduced a model with the X-axis being a time base, for time-oriented data. In the early 1960s, Moseley and Sanborn companies were both represented by many of the same Sales Representative companies as HP, so all the principals knew Packard and Hewlett. Which led to HP purchasing both of those companies. Moseley's technology advances were clever. Pen based recorders exhibited maddening shortcomings, with the marking pens drying out when unused, faulty line widths, and other traits which they overcame. Just a mundane factor like holding down the paper on the flat platen was sometimes agonizing. So those clever engineers invented a ceramic coating, with HV traces underneath, to firmly capture the paper with electrostatic effects.

HP 9100A and HP 7200 Plotter, circa 1969 With the success of the Moseley Division product line, they needed to expand out of their downtown Pasadena location, and bought property further east in Covina, CA. Unfortunately in those years, the gasoline-generated smog blew eastward out of the congested Los Angeles basin into the San Bernardino Valley, where it mostly stayed between mountain ranges. A newly-appointed Division Manager from Colorado, accustomed to clean air, flew in to inspect the building site, hit a bad smog day, and pronounced that he would not move. This led to abandoning LA for a beautiful building site in Rancho Bernardo, north of San Diego. The recorder product line moved there, and grew rapidly, later picking up the magnetic tape line from the Microwave Division and the acquired Datamec recorder products from Mountain View. As technical desktop computers were introduced, starting with the HP 9100A in 1968, you knew that engineers would immediately insist on coupling them to X-Y plotters, to aid their design analyses. These two pix show the HP 9100A and the San Diego HP 7200A plotter. Dramatic new desktops were introduced quickly in succession. These capabilities showed unfilled customer needs in paper plotting. One obvious example was to attack the huge demand for a way to automate large engineering drawings. I suppose most of us have seen pictures of the engineering departments of airplane companies like Douglas and Boeing. There, dozens if not hundreds of draftsmen are sprawled across drafting boards, manually drawing the fabrication and assembly drawings that will create an airplane. These are drawings that might be 3 feet high and 6 feet long. This period is long before the application software technology will permit making those drawings that can be electronically applied to the actual building of an airplane. Thousands of architectural firms across the world did ALL of their creation with manually produced large format drawings. The emerging semiconductor industry needed super-accurate overlaid drawings of the multiple processing layers of integrated circuits, to photographically define each diffusion or metallic layer. Marv Patterson came on the HP San Diego scene in 1973 after some creative US Navy missile test designs. As his fascinating story tells us, his management proposed the quest, to develop a plotter which could handle paper as wide as 36 inches, and as long as necessary. And suddenly, his design team was on its own, as was almost always the case at HP engineering. Several competitors did have large format plotters, exorbitantly expensive, and moving the paper with sprocket holes, which had awful repeatability. Then serendipity intervened. In 1972, HP introduced its HP-35 hand calculator, a scientific wonder which did exponential, trigonometric and transcendental functions with the click of the keys. As sales ran to hundreds of thousands, those fertile minds at HP Research Labs were trying to figure out how to design a tiny page plotter, to sit on a cluttered engineer desktop and plot HP-35 data on ordinary 8.5 x 11 paper. They had come up with an ingenious paper mover, using a new concept called a grit wheel. The idea was to grip the paper, on its 11-inch edge, between two wheels about 1.2 inch diameter, a rubber wheel on top and a bottom wheel with a sandpaper-like grit surface. Some bright engineer had figured that by embossing the surface of the piece of paper with the sand protuberances, that when the paper moved backward, it would fall back into those tiny embossments. The whole mechanism footprint was only about the size of a medium book. Word of that grit wheel technology got to the team in San Diego, immediately solving the repeatability of the sprocket drive technique. But the most impressive accomplishment of Marv's story is how they gained marketing insights. They visited many potential customers for large format plotting to understand the jobs their plotters were expected to do, and the product features that were essential to each task. The resulting large plotter was a true product breakthrough, fast, brilliant plot graphics, low cost, reliable, and a real winner with customers. You will find Marv's story rewarding, a tale of clever design and management excellence. Pen plotter technology served for several decades, until manufacturing automation forced the entire design-to-fabrication process to be handled strictly by computer systems across the factory. Bye-bye plotters and paper drawings. But Marv's HP Memoir is most impressive because he thought so analytically about management leadership and creativity. He moved from San Diego to what we used to call HP Intergalactic Headquarters in Palo Alto, and took part in management attempts to streamline HP product development efforts throughout the company. The vision was to stop redundant engineering, consolidate investigation into CAD systems, and discover and establish more effective practices in areas such as project management and software design. The bad news was that HP divisions grew up feeling self contained and self assured that they could sponsor new technologies and practices within their own organizations (stovepiping-not sharing). Marv noted that often engineers in one division would only learn of applicable work in another division when a particular product was introduced to the world with a seminal article in the HP Journal. This was a necessary but insufficient method for spreading the word on engineering excellence taking place within the company. John Minck |

Discovering the Fundamentals of Hard-Copy Graphics and Innovation Management;

The HP 7580 (Big Bertha) Story and What Happened Later

,

by Marvin Patterson

Update: Since leaving HP in 1993, Marv has continued working on improving the effectiveness of new product innovation in a business enterprise, a project which was first assigned to him by John Young in 1992. He applied his increasing expertise as a consultant until 2018 and, in retirement, has produced a video series called: Creating Breakthrough Innovations. This series of seven videos introduced in July of 2020 provides a clear and comprehensive answer to this very important question: What do innovation professionals in a business enterprise - at all levels, executive to individual contributor - need to know that will enable them to deliver an unending sequence of new products and services that consistently surprise and delight customers and users? These lectures can be viewed at the following link: Creating Breakthrough Innovations.

Discovering the Fundamentals of Hard-Copy Graphics and Innovation Management;

The HP 7580 (Big Bertha) Story and What Happened Later

,

by Marvin Patterson

1. Beginnings

I was born in Ontario, Oregon in 1940. My dad, a construction worker, was employed on the Owyhee Dam project. He met my mom when she, her mother and her sisters all traveled to the project from Nyssa, Idaho to provide hot meals for the workers. After they were married, his work at the dam site lasted quite awhile; long enough for my oldest brother, Dwight (born in 1931), my middle brother, Ron (Born in 1936) and me to all be born in Ontario. Soon after I was born my family moved to Washington and settled on a small farm half way between the towns of Kirkland and Bothell.

In 1945 my family moved perhaps 10 miles away to a house in Kenmore, Washington, located at the northern tip of Lake Washington, where I would live until I graduated from nearby Bothell High School in 1958. I started school there in kindergarten the year we moved to Kenmore, and formed a number of close friendships that were important all the way through to graduation, and still are to this very day. My school friends and I do not get together often, but when we do, our friendship continues on from exactly where it left off.

2. Novice

Growing up in Kenmore, I was always tinkering with or making something. And I developed an early fascination for electricity. In our basement one evening, I found a power cord from some appliance that just ended in two exposed wires. Of course I plugged it into the wall, and soon discovered that I could make really cool sparks. Before long I learned to hold one bare wire tight against the metal of a cooking pot with my left hand, while arcing craters in the bottom of the pot with the other hand to spell out my initials.

Before long I heard my dad stomp across the floor above my head and throw open the basement door. "Marvin, what are you doing down there?!!"

"Nothing," I replied.

Later, when I was in the 10th grade, my interest took a more sophisticated turn when I saved up and purchased a 10 in 1 Electronics Kit. It included three vacuum tubes plus a photocell along with the usual resistors, capacitors, transformer and such. Not knowing at all what I was doing, at least I could follow directions. And, once my mistakes were found and corrected, the circuits would work as advertised.

One particular circuit fascinated me the most - a radio transmitter that allowed you to broadcast your own voice to a nearby radio. I remember the directions were very adamant, "Do NOT, under any circumstance, attach an antenna wire any longer than five feet." So naturally I ran the antenna wire out of my bedroom window and all the way down to our aluminum-wire clothesline in the back yard. All in all, there was perhaps 150 to 200 feet of effective antenna. Next, I tuned the transmitter to KJR's frequency, tuned the radio by my bed to KOMO, taped down the "Talk" button and propped up the microphone next to the radio speaker. Then I borrowed my mom's car keys, tuned the car radio to KJR, and started driving. Sure enough, I was hearing KOMO over the KJR channel. By actual measurement, my rig managed to jam KJR's signal over an area about a half-mile in diameter, and replace it with KOMO's broadcast. I wonder what the neighbors thought about this if they were listening.

Not having a driver's license at the time, I wisely returned the car to the garage and disassembled my radio experiment.

After graduation in 1958, I enrolled in the University of Washington engineering school, and made the obvious choice of electrical engineering as my major. My parents were divorced by this time and there was no money for college, so I was on my own. Jobs were hard to find and it was nip and tuck there for quite awhile. I worked in a gas station for a short time, then a lumber mill. Next I learned to operate a pick and shovel as a laborer digging ditches. Things began to look up though when my brother got me a job at the building materials yard where he worked as a delivery truck driver. There I learned to drive a forklift, and actually worked up to delivering materials to job sites myself with a flatbed truck. These were all summer jobs, though, so I would usually be forced to borrow money from my dad for spring quarter tuition.

Paying him back the following summer would then put me behind in building my nest egg for the next academic year. In my junior year I finally landed a full-time job at the Boeing Company which provided the longed for year-round, steady income. l worked swing shift from 4:00 in the afternoon to midnight as a pyro-metrics technician measuring temperature accuracy and uniformity in heat-treating ovens and oil baths. Things improved even further a bit later when I got a job with IBM as a customer engineer. They assigned me to work right back at Boeing on their data collection system. Now working graveyard shift from midnight to 8:00 in the morning, I once again spent my time toiling in various shops on the factory floor, only this time wearing a freshly pressed suit and tie.

In those days the EE curriculum at the U of W was heavily influenced by the school's relationship with Puget Sound Power & Light Company. Thus I learned far more than I ever wanted to know about three-phase power distribution, large transformer design and heavy rotating machinery. In addition to basic circuit theory, though, there were some electronics courses. All of them except one, though, focused exclusively on design with vacuum tubes.

I took the one available transistor design course during the last quarter before I graduated. I think the professor was about one chapter ahead of us in the textbook. That book described transistor operation using only the r-parameter model. Consequently, when I started my engineer career with the Pacific Missile Range at Pt. Mugu, California in the spring of 1963, I found myself initially incapable of designing a transistor circuit. Transistor manufacturers preferred the h-parameter model and only included those values on their spec sheets. The numbers I needed to apply what I had learned in class were not readily available.

3. Competent

Pacific Missile Range, Pt. Mugu, CA

In their first year at the Pacific Missile Range, new engineers were rotated through three four-month-long assignments in different functional areas at the naval air station. My second assignment was with the Instrumentation & Flight Support Division. This group was responsible for designing and implementing the telemetry systems used on all of the weapons system flight tests. They also provided the data receiving and recording capability that was used during test operations, and then decoded and published the data that was gathered.

The engineers that developed these telemetry systems were extremely capable in all of the technologies involved; including ground and airborne antenna design, transmitters, data encoding, signal multiplexing and modulation, receivers, demodulation, and finally data recording and display. Furthermore, they seemed agreeable and even eager to pass what they knew on to a fledgling engineer. This was exactly the intellectual cornucopia that I sought. I thoroughly enjoyed my four months there, and left with their promise to accept me back when my three tours of duty were complete.

When I finished my third assignment, though, I was told that I would have to pick either my first or third assignments. This happened because Instrumentation & Flight Support was part of the Naval Missile Center, another tenant organization at the Pt. Mugu Naval Air Station, and not part of the Pacific Missile Range group that had hired me. When I refused, my case was move up the management chain to the next level. I kept refusing at each level to take one of these other assignments, and soon found myself in the office of the highest-ranking civilian executive at the Pacific Missile Range.

He reiterated the, by now, familiar rationale for this obvious necessity, and assured me that he was confident I would make the right decision. I agreed with him on that, but pointed out that the only decision criteria I was considering had to do with what would be best for my career development. Satisfying Pacific Missile Range policy was a much lower priority. I pointed out that, in tours #1 and #3, none of the engineers that I met seemed to have the depth and breadth of knowledge that was plentiful in Instrumentation & Flight Support. The right decision from my perspective was clearly to get into that organization, no matter the cost, and learn how to do electronic engineering.

At this point, I described the only two alternatives that were available to him and I, going forward. One, he could relent and let me gracefully transfer to Instrumentation & Flight Support. Or two, I would resign from the Pacific Missile Range. Once that complicated and expensive process was complete, and I was standing on the street out in front of the base, the folks at Instrument & Flight Support would then hire me on the spot, and go through the expensive and complicated process of bringing me back on board. He made the right choice, and thus my Civil Service career got off to a good start.

Once settled in my new position, I formed working relationships with several excellent engineering mentors. The four to whom I owe the greatest debt of gratitude were; Ted Waddell, Merle Beckman, the late Claude Gorevin, and Jack Martin. "Don't know how to design with transistors? No problem! Here's how you do it. Need to know how a VHF antenna works? No problem! Let's talk about it. Having trouble getting things done because of the Civil Service bureaucracy? No problem! Here's how you work around that." I soaked this all up like a sponge in a bucket of water.

Before long I was considered one of the "can do" engineers that attracted the toughest assignments. One day, for instance, my boss came to me saying, "We need a VHF range timing receiver for an airborne telemetry system really soon, like maybe yesterday. The folks in the other division who have been responsible for designing one are hopelessly behind schedule. Drop what you are doing and cobble something together that we can use."

Within a month I had a single channel breadboard receiver running that passed the operating temperature and sensitivity requirements, but had a few shortcomings. First of all the automatic gain control response was painfully slow and, secondly, the design needed to be implemented in printed circuit form and packaged. The first flight operation was the following week. What to do?

No problem! The shop foreman found a suitable aluminum enclosure and had the necessary connectors installed. Then he made a form shaped like a brick, placed my working breadboard carefully in the center and, poured liquid potting compound over the whole mess. I was horrified! Those radio frequency circuits will never work right encased in that stuff! But they did. Once that solidified brick was placed in its box and wired up, the end result looked really professional, and it was on time for the first flight test. More than that, it ran flawlessly throughout the next year and was retired only after the last flight test was completed.

While these flight tests were underway, I finished the design and packaged the receiver in an indestructible aluminum case that was watertight. Once it was assembled, this device could survive a parachute drop into the Pacific Ocean and be reused the next day. The unit manufacturing cost was only $50. Over the next several years, we made and used dozens of these receivers.

Things continued like this for the next couple of years with challenging new assignments that each taught me something new and important. Then one day that changed. The next assignment was to design a telemetry system very much like the one I had just put into service. A thorough review revealed absolutely nothing novel or interesting about this new project, and my enthusiasm for the job just plummeted. I could hardly force myself to go to work each day. Through this experience I discovered that the secret sauce that kept me engaged with my work was, in calculus terms, "d(Learning)/d(Time);" the rate of new knowledge gained per unit time. When that went to zero, so did my level of motivation. I clearly had become a "learning junkie."

Pursuing a Master's Degree

The scheme I came up with to rectify this issue was to apply for one of the graduate school scholarships that the Pt. Mugu Naval Air Station granted each year. When the winners were announced, though, I had been passed over. Really disappointed, I asked my boss why I had come up short. His response was completely unexpected, "On the contrary, Marv. As it turns out your application was too good. There is another program in which the US Navy issues a dozen or so Weapons Control System Engineering (WEPCOSE) scholarships each year nation-wide. The review committee felt that you might have a good chance to pick up one of these. Assuming that you would, they awarded your local scholarship to someone else. If, for some reason, you don't win a WEPCOSE scholarship they will send you back to school next year."

The winners of the WEPCOSE scholarships were determined by the results each applicant achieved on a rather amazing and intense daylong exam. By sheer luck, candidates from all over the US who were nominated for this scholarship traveled to Pt. Mugu the very next month to take that test. I must have done pretty well because, as it turned out, I did win one of the 13 scholarships that were granted that year.

In August of 1968, my wife and I leased our house in Camarillo, packed our belongings into a U-Haul trailer, loaded our two small boys into the car, and left for Seattle and the University of Washington.

Once we were settled in the Great Northwest, my level of d(Learning)/d(Time) really took off. I was enrolled in a three-quarter series of courses on graduate-level electro-magnetics that started in early October, and I had never taken one of the prerequisites for that first class. So I bought the text for the missing course and spent September preparing my brain for the upcoming intellectual marathon. Once fall quarter got underway I discovered, for the first time, the luxury of not having to budget my time between course work and income-producing work. For the year to come my salary was assured, and all I had to do for it was study. Under these new conditions I also discovered that I was a really good student, and able to pull in high grades.

While my main academic focus was electro-magnetics, another topic of interest caught my eye in spring quarter. I enrolled in a class entitled "Active Network Synthesis" and discovered that a number of Boeing engineers also had enough interest in this topic to take time off from work to attend. Our professor, probably the youngest person in the room, immediately established a highly theoretical line of study. It was a ten-week course and at week four we were still trying to wrap our minds around network realizability criteria. Along the way we had been exposed to hypothetical network components such as gyrators, mutators, voltage-controlled current sources, and current-controlled voltage sources. The Boeing engineers by this time were seething and ready to revolt. They wanted to learn things that would actually enable them to do better work for their employer. As one Boeing fellow put it to the professor, "When I go to the supply cabinet at work, I can't find the bin where "gyrators" are kept, nor can I find mutators in stock. How do you build these things?"

Our young professor was really caught at a loss and seemed to need help in the worst way, so I spoke up. "I recently got a patent on what I called a Synthetic Inductor circuit. Since starting this class, though, I know now that it should have been called a gyrator. If you would like, I would be happy to describe this circuit to the class next week, and also how to implement some of these other theoretical network elements with transistors and operational amplifiers." The professor, quite relieved, and the Boeing engineers were unanimous in their acceptance of this proposal.

So I taught the next two lectures, peace was restored, and I made some new friends at Boeing. Apparently the young professor was also appreciative because he must have told his superiors what I had done for him. At the end of my year at the U of W, the chairman of the EE department called me in and offered me a job teaching in the department. He observed, "Sometimes I think we have gone way too far in our theoretical work. Some of what we have done seems like it may not be needed for another 400 years. We need to balance our curriculum with more practical material." I appreciated his offer but told him I couldn't really consider it at the present time. I had agreed, as a condition of my scholarship, to work at least three more years for the Navy after my return.

4. Experienced

U of W Thesis Work

That summer was spent in the U of W EE department finishing the experimental work for my Masters thesis. My topic was acoustical holography applied to moving systems. To accomplish the experiments required, I designed and built a synthetic aperture, (side-looking), sonar system operating in water at 5.0 MHz that utilized a single transducer immersed in a fish tank. This transducer transmitted and received acoustic energy within a 30-degree beam. Moving acoustic targets were passed laterally through this field of sound and created holographic patterns on an oscilloscope screen. These holograms were then captured on film and converted to transparencies. Images of the moving acoustic targets were created from these transparencies by illuminating them with plane waves from a laser on an optical table. The output images were then recorded photographically. Before I left the U of W in August 1969, I successfully presented my results and defended my thesis.

After I returned to Pt. Mugu, I finalized and submitted my thesis to the U of W. The Navy also published and circulated it as an official Naval Missile Center document (TP-70-39 (U)). I received my MSEE degree in August 1970.

Final Years in Civil Service

After I returned to Pt. Mugu, my intellectual pursuits proceeded down two paths simultaneously; active network synthesis and microwave design. Use of frequency-selective circuitry was crucial in telemetry systems, and design techniques were emerging at the time for implementing these circuits using only resistors and capacitors along with active elements such as operation amplifiers or transistors. I wanted to understand and master these techniques.

At the same time the US was involved in the Vietnam War, and the Instrumentation & Flight Support group had become a quick response resource for technical solutions to issues that occasionally arose during that conflict. These solutions often required design at microwave frequencies of system elements such as antennas, multiplexers or special purpose receiving systems. I was occasionally asked to work with Navy personnel to understand these requirements, and then implement the solutions; with my technician and I either working as a team or in collaboration with various defense contractors.

|

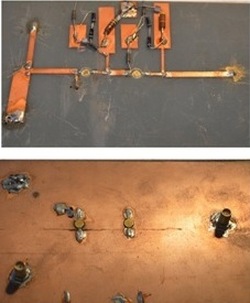

S-Band amplifier from 1972 class on microwave circuit design at HP. |

In 1972, I learned of a weeklong microwave circuit design class offered by Hewlett-Packard in Palo Alto, and convinced my manager to send me. That experience changed my life dramatically in several ways. First of all, I learned to do microwave design with s-parameters, which made far more sense that any other method. Secondly, I met and fell madly in love with the HP 8410S microwave network analyzer. During the course, we used one of these to great advantage in designing a two-stage S-band amplifier. And third, I fell in love with HP as a place to work. Everybody I met there was very friendly and so very knowledgeable. And everyone was enthusiastic and seemed to have fun at work; so different than civil service!

Immediately on my return to Pt. Mugu, I began maneuvering to acquire an HP 8410S and all of its associated accessories. I simply lusted to have that capability at my disposal! It finally got on the budget, ordered and shipped in the spring of 1973.

In the meantime, though, news of a reduction in force (RIF) at Pt. Mugu came down from our leaders in Washington D.C. According to civil service rules, certain jobs would be eliminated, and people in those jobs would be allowed to find other jobs for which they were qualified. They could then bump the people who currently held those jobs, so long as they had seniority over that person. Those folks, who were bumped, could then do the same to someone else. In this system, there was no way to predict who would actually end up leaving, but surely the number that left would eventually equal the original number of jobs eliminated. The obvious flaw in this bureaucratic process was that many projects would lose their continuity as new faces moved into unfamiliar jobs.

I had recently been promoted to a GS 13 level, and had less seniority at this grade than anyone else on the base. With these rules in force, I was certain to; 1) get bumped back to a GS 12, 2) lose my job, and 3) end up taking a job I didn't want from someone else.

Joining HP

I had finally had enough of civil service, and began looking for other work. I had two main regrets in leaving Pt. Mugu, though. First, I loved the people with whom I worked and would miss them. And secondly, I agonized over leaving that HP 8410S equipment behind. I had barely unpacked it and, besides, I wasn't aware of anyone else at Pt. Mugu who knew how to use it.

Soon after I started my job search, I saw an engineering job opening that the HP San Diego Division had posted in the Los Angeles Times. I applied and they invited me down for an interview. When I learned that they developed various data recorders, I made it clear that I really wanted to pursue microwave design. They interviewed me anyway and said that, if I passed, they would inform the Santa Rosa Division of my availability. I did pass the interview, but Santa Rosa's response was that they were not interested. I was too old (age 33)! Nonetheless, the folks at San Diego, and the working environment there, were even better than I had experienced during my Palo Alto visit, so I accepted their offer, and reported for work the first week in September, 1973. Later I would tease my San Diego colleagues that coming to HP reduced my bandwidth from perhaps 10 GHz to just a few kHz.

Wanting to leave my crew at Pt. Mugu some sort of legacy, I wrote a white paper describing what I had learned about active network synthesis, and left it with them. I also submitted it to the Electronic Design News (EDN) magazine for publication. They published it as a three-part series beginning in August 1974.

|

San Diego Division X-Y Plotter products |

San Diego Division's products at that time were reminiscent of those that were developed by the F L Moseley Company and, later, the HP Moseley Division acquired by HP in 1958. They included x-y and strip chart data recorders as well as instrumentation tape recorders. HP desktop digital calculators were just becoming available from other divisions, so San Diego had added a digital interface to one of their x-y recorder products to enable it to create plots directly from the output of a calculator program. These digital plots, though, were quite slow to generate, and not very precise.

HP's programmable calculator products were becoming increasingly popular resources for engineering laboratories everywhere, so demand was very strong for a more capable graphic plotter. The San Diego Division executive team recognized this and launched several new R&D projects in response to this need. Most were aimed at developing various desktop products that would work with the digital calculator. The one I was assigned, though, was different.

Opportunity Discovery Assignment

One day in 1974, Tom Tremble and I encountered each other pacing back and forth in the hallway outside of the closed door of the HP San Diego conference room where division executives were holding their monthly staff meeting. At the appointed time, we were ushered in where we received an unexpected assignment, "We want you two to figure out what it will take to get HP into the large format drafting plotter business. Work at this about half time, and report in with us every other month or so to let us know what you are learning. Spend whatever you need on travel."

In less than 15 minutes we were back out in the hallway looking at each other, puzzled. We hardly knew one another. Tom was a product-marketing manager and I was a project manager in the R&D lab. Over the rest of that year and part of the next, though, we became good friends and learned much together.

The Large Plotter Market

In the late 1970s two firms, Calcomp and XYnetics dominated the US market, while a French company, Benson, held sway in Europe. Calcomp offered innovative designs that held the record for acceleration and plotting speed. Their most recent offering, for instance, utilized a Mylar belt moved by sprocket rollers at top and bottom. The drawing medium was taped to this belt which then moved the drawing surface back and forth underneath a pen carriage moving right to left above the top roller. This machine sold for about $30,000.

XYnetics machines were the gold standard for accuracy and were built with a base made from a polished granite slab weighing about 1000 lbs. A waffled steel plate embedded under a smooth plastic layer was bonded to the top of the slab, and the drawing medium was taped to the smooth upper surface. An x-y motor carrying four pens was moved around by magnetic forces, and suspended above the drawing medium on an air bearing. The cost for such a machine was around $50,000 or more. Once this plotter was in place and temperature stabilized (a process that could take a couple of weeks), it delivered unparalleled accuracy.

These machines were used to create drawings of all kinds; mechanical, electronic schematics, architectural, and more. Really accurate plots were sometimes used as templates in fabricating finished goods such as clothing or large sheet metal parts.

Market Insights Discovered

In discussions with an architect in Bath, England we learned that a liquid ink pen failure could cost $1000. He had designed a strip mall that was being replicated again and again in Saudi Arabia. Local regulations demanded that each drawing be plotted on Mylar with India ink. His days were spent cleaning liquid ink pens, and keeping his half-dozen large format plotters constantly running. "When you break it down," he said, "Each of these drawings is worth about $1000. When a pen clogs or dries up in mid-drawing, I have to throw the whole thing away and start over."

As almost an after-thought, he added, "Oh, by the way, if you plan to sell me plotters, you had also better be able to supply me with pens, inks and drawing media. My nearest drafting supply store is in London. It costs me a whole day to get there, buy what I need, and get back here."

Back in the US we visited an integrated circuit design company in the Boston area. There we saw several big XYnetics plotters in action turning out plots that depicted individual layers of a chip design. When I asked, "Can you show us how these drawing are used?" we were ushered into a huge room filled with large light tables about two feet high. Each had several large and carefully aligned drawings taped to its top surface. Engineers in white lab coats and booties were crawling around on top of each light table sighting down through the drawings to ensure that each layer was correct, and well aligned with layers above and below. I know that computer software does this job now but back then that's how it was done.

Our host pointed out, "You can see now why we need such accurate plots. Each individual drawing needs to line up perfectly with the other layers." I observed that they weren't really depending on accuracy. They were using repeatability. Each long line could be short by perhaps a half-inch and, as long as all plots were in error by the same amounts, the drawings would still line up, and their process would work just as well. He grudgingly admitted that this might be true. As long as all plots for a given chip were made on the same machine, high repeatability with lower accuracy would work just as well. This could be accomplished with a much less expensive plotter.

Finally, during a visit to a construction site in the desert about 20 miles out of Phoenix, Arizona, a civil engineer told me, "If you want to sell me a plotter it needs to fit in this little temporary office here. Also know that I'll either buy your plotter that year, or a new pickup truck. So your plotter had better be more valuable to me than that new pickup truck."

Discovering the Essentials of "Drafting Quality"

Knowing that the unit manufacturing cost (UMC) of our eventual product would be driven by various product specifications, e.g. accuracy, repeatability, pen acceleration, and pen handling, we launched a technical investigation into this concept of "drafting quality" and the plotter performance constraints that would be essential in achieving it. Hundreds of archived drawings created by humans were studied in minute detail to develop a performance baseline.

They proved to be a tough act to follow. Lines were always impeccably straight, and the smallest details were nearly perfect. India ink drawing pens, for instance, leave a little, round blob at the end of a line where their motion has come to rest. The diameter of this blob is about 1.5 times the width of the line. Many draftspersons will follow up by trimming these blobs even with the line edges with an X-Acto knife. In our investigation we learned that this blob takes time to form so, if the pen is lifted or the next line segment leaves from that point within a few milliseconds, it doesn't occur at all.

Knowing that designing our product to perform as well as a person would increase its UMC prohibitively, we decided to explore the human observer's ability to visually detect flaws in a finished drawing. The test bed for our work was a breadboard consisting of a large, 36-inch-wide flatbed plotter along with the external computers, motor drive electronics, and power supplies that were required. We learned that deviations from a straight line that occur repetitively over short distances, an inch or less, will be noticeable if they are more than about 0.001 inches in magnitude. On the other hand, a long line of 36 inches can smoothly deviate by as much as 1/2 inch in the middle, and still look straight to the unaided eye. This study provided essential design guidelines for our product.

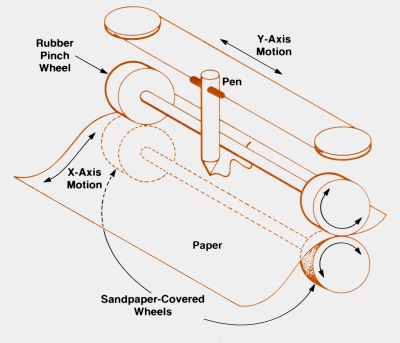

Bill Hewlett Starts a Side Project

During the time we were working with this large flatbed, HP's San Diego division had its annual review with the company's executives. These reviews always included a tour of key projects in the R&D lab. When Bill Hewlett saw our big flatbed, with its huge 1 hp servomotors and massive external power supplies he wondered why all that hardware was required to move around a teensy 1/2 oz pen. This was a good question, and Bill later discussed it with his friend, Larry LaBarre, at HP Labs (HPL) up in Palo Alto. "Why don't you invent a better way to move a pen around on paper?" Bill asked.

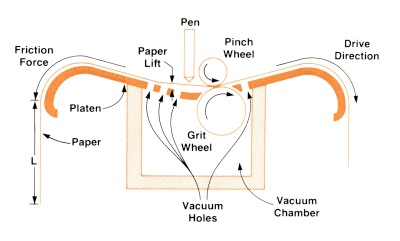

Thus the "Sweetheart" project was born, and a small breadboard plotter was eventually created that moved a letter-sized sheet of paper forward and back between sandpaper-covered rollers and rubber pinch wheels gripping the left and right edges of the paper. A pen moved left and right above the paper along a horizontal track. Compared to our big flatbed configuration, the inertial loads that had to be accelerated were miniscule.

BS-ing Barney, And Living to Tell About It

Four of the five people working on the Bertha project were, for a time, pulled away to work on line quality issues that the HP 9872A project was having with its lab prototype unit. The design fundamentals we had discovered that underpin a machine's ability to move a pen along a perfectly straight path between two arbitrary points needed to be applied. In addition, we needed to correct the nonlinear performance of the stepper motors that drove the x and y mechanisms.

Regarding stepper motor linearity, we developed a way of empirically deriving the complex current waveform that would cause a given stepper motor move in a perfectly smooth and linear fashion. The thought was that, if we could get the manufacturer to build sufficiently uniform motors, we could create a waveform generator that would cause corrected, linear motion. We then engaged a stepper motor manufacturer who believed that they could develop special motors for us that were sufficiently uniform in their characteristics.

During the time we were doing this work, we were visited once again by HP's corporate leaders for our annual division review. One of the projects reviewed was our stepper motor work and, of course, Barney Oliver was there and asked the most questions.

About an hour after our demonstration Barney came by my desk to discuss this motor problem. He began, "You know, Marv, I think what you need to do is have them fabricate motors with sinusoidal rotor and stator teeth." I agreed that sinusoidal magnetic forces would do the trick, but that magnetic torque was a highly nonlinear function of the air gap between the stator and rotor. While the stator and rotor teeth should be rounded, not square, the actual shapes should be adjusted to create a purely sinusoidal magnetic force.

Then I said, "I think I might be able to calculate these corrected shapes using circular harmonic expansion techniques." This was a methodology that I had seen applied in calculating the radiation patterns for antennas mounted on a conducting cylinder. The words "circular harmonic expansion" actually caused Barney's eyes to glaze over a bit.

Recovering quickly, he nodded and said, "Yeah, that might work," and then he walked away.

The next morning it took me only about 20 minutes to realize that there was absolutely no merit at all to my idea. I was, most certainly, the newest member of a very small population who had ever slipped such a huge error past Barney.

The HP 9872A Third Harmonic Stepper Motor Drive

When we got a batch of six "uniform" motors from our stepper motor manufacturer, we quickly characterized the ideal waveform for each motor. They were all similar in shape but not exactly the same. To compensate, we calculated the average waveform that best represented the group, programmed it into our HP 9872A motor drive electronics, and performed a line quality test. At the critical angles, both the x and y drive systems created noticeably wavy lines. {Sigh!} We swapped out the first pair of motors for the other two pairs, and got essentially the same result each time. Our whole approach to corrected stepper motor control was apparently unworkable.

Those of us who had worked up this scheme over the past several months were stunned; just speechless. After a short time, though, I felt a kind of rush of excitement and said to the others, "What we need here is an adjustable waveform. I'm going to go invent how to do that."

The rest of that day I reviewed the harmonic structure of the corrected waveform for every stepper motor we had ever tested. They, in general, were made of a fundamental sine wave and its odd harmonics. In an ideal motor the current waveform that created linear motion would be a simple sine wave. The corrected waveforms had these higher harmonics to create linear performance. The striking thing I eventually noticed was that, in each case, the energy in the third harmonic was always at least ten times higher that of any other harmonic. The epiphany: Why don't we just throw out these wimpy higher harmonics, and add an adjustable third harmonic correction?

The next morning I designed a circuit that used several analog multipliers to implement and combine trigonometry relationships in a way that converted a sine wave into its own third harmonic. This output was then combined with the original sine wave so that it could be added or subtracted in variable amounts. The output waveform proved to be so adjustable it could be made to look much like the correction waveform for any motor we had analyzed.

Two of these analog circuits, one for each axis, were added to our test set up, and our waveform generator was altered to put out a pure sine wave. With everybody gathered around holding their breath, we began to install motors and test their line quality. In every case, we could adjust the wavy line problem down to absolute zero. The disaster of the day before had been transformed into triumph. Not only did we not need the expensive special stepper motors, we could make any available stepper motor behave smoothly.

In the final product the analog correction circuitry was replaced with a much more effective and less expensive digital solution. When it was introduced, the line quality produced by the HP 9872A was unrivaled.

Big Bertha Becomes the First Grit Wheel Plotter

|

Two grit wheel drives move the paper. |

Once the HP 9872A line quality issue was resolved the Bertha team was reunited. Soon after, we learned of the Sweetheart project up at HPL and the little plotter they had invented. I traveled north to have a look and was very impressed. Ever the skeptic and probably suffering from a touch of Not-Invented-Here (NIH) syndrome, I concluded, "It works great for a piece of notebook paper, but it would never work for a D-size (24" x 36") sheet of drafting medium." And I returned to San Diego.

One week later I received a call from Chuck Tyler, the HPL Sweetheart project leader, "Marv, would you like to come back up and take a look at our D-size drafting plotter?" They had run one of their letter-sized machines through a band saw and cut it in two, right down the middle. Extensions were welded in place to move the left and right halves far enough apart to handle a 24" wide sheet of paper. This was clearly one of the most dramatic and creative R&D short cuts I've ever seen.

George Lynch and I flew up see what they had achieved, and were convinced that this approach was the way to go. Upon our return, though, we ran into resistance from division management. They had more confidence in the step motor drive we had invented to run the HP 9872A plotter, and depending on sand paper for our product success apparently made them nervous. We were told to shelve the grit wheel drive idea, and revisit it sometime in the future.

Over the next week our small project team was in the doldrums. However, a few days into it George Lynch, our mechanical engineering lead, took a stand. "Marv, I'm the ME lead on this effort. Why can't I decide on the best mechanical approach to achieving our product performance goals?"

"I don't know, George." I responded. "You should be able to make that call. I'll ask Larry (our Section Manager). Larry couldn't give me a good answer, so he said, "I'll ask Tom (our R&D Manager)." Tom was traveling, so the next morning (a Saturday) Larry met with the Division General Manager over the coffee table in his home. He couldn't come up with a good answer to George's question either.

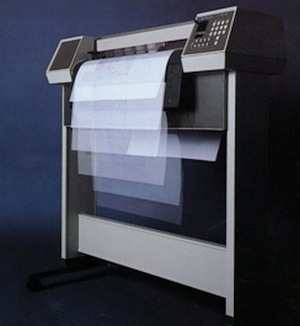

|

HP 7580A plotter, "Big Bertha" |

Early the following Monday morning, the General Manager confronted me, nose to nose, at my desk in the lab. We agreed that, if the grit-wheel mechanism turned out to be the wrong choice, then I would be guilty of slipping my project one week per week until I realized this, and got back on the right track. When George came in a little later, I said, "George, The GM was just here. We are doing a grit-wheel drive."

George's response was a classic, "Great! Can I have the model shop run our big flat bed through the band saw before anyone has second thoughts?"

And that is exactly what we did. Before morning coffee break that big machine had been reduced to scrap.

Development Engineering Begins

Development of the first HP grit-wheel drive plotter thus began in earnest. In some ways, this was like every other plotter project we had done in the past. The major development engineering efforts included:

- An X-Y plotting mechanism.

- A pen handling system.

- X- and Y-axis control systems.

- Electronics and a microprocessor for turning incoming data into X-Y motion.

- An effective industrial design for the product.

|

The only serious inertia to moving the paper is the paper itself. |

One important thing was different here though. The HPL team had given us a terrific idea and a demonstration of an operating breadboard, but they had not provided design rules, critical success factors, or decision trade-off criteria for the all-important grit-wheel drive technology. If we were to develop a product with HP-class performance and reliability across all operating environments, we needed to develop this essential knowledge ourselves. A small team of engineers was given the assignment to; 1) establish the physics underpinning a successful grit-wheel-to-plotting-medium interface, 2) determine the failure mechanisms and performance limits of this interface, and then 3) implement physical tests that demonstrate that their theory really describes the reality of grit wheel performance.

|

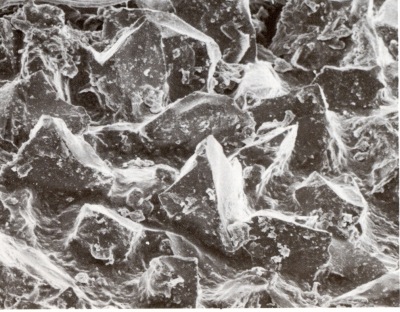

The gritwheel surface looks like this under 132X magnification. It embosses the paper passing through for unique repeatability. |

Once this work was done, the design of a reliable grit wheel mechanism became feasible. Key elements of this design involved sifting aluminum oxide grit to select out the ideally sized grit particles. Then aluminum rollers were sprayed with adhesive to just the right depth, and the selected grit particles were sand-blasted onto the still wet adhesive with enough force to embed them to a depth that left, on average, 1/3 of each grit particle exposed above the adhesive. These grit wheels, when working against a pinch roller with just the right hardness and pinch pressure, would then deliver without fail the performance needed over the full life of the plotter.

Dinner with Barney

On the night before our division review, in the fall of 1979, I was working late in the R&D lab at HP's San Diego division. Around 5:30 or 6:00 p.m. someone came through the lab, in a bit of a panic, calling out "Does anyone here know what Barney Oliver looks like? I responded that I did, and was immediately assigned the responsibility of meeting Barney's flight at the San Diego airport, and delivering him to his hotel in Rancho Bernardo, which was roughly a mile from our site.

I called home to let my wife know I would be late, grabbed some food from the vending machines and headed for the airport. The timing was good and I was there waiting when Barney emerged from his airplane. We had met only briefly before at earlier reviews, and I had talked to him on the phone once or twice seeking advice on various R&D issues. Not only were we barely acquainted, I was a lowly R&D section manager with the ink barely dry on my recent promotion, and he was the most famous technologist in the World's greatest technology company. To a techy nerd like me, this was like a normal person being asked to gather up a rock star, and escort him to his hotel.

We made small talk on the way to his hotel, the Rancho Bernardo Inn, and I told him a little about my work in the R&D lab. Near the end of our ride, he asked if I'd had dinner, and I told him that I'd grabbed a bite to eat before I headed south to pick him up. Sensing that he might like company, though, I offered to sip a glass of wine and keep him company during dinner. "I'd like that," he said.

"Oh boy, now I've committed to spend an hour or so with this guy!" I thought. "What on Earth will we find in common to talk about?!!"

That turned out to not be a problem at all. Once he had ordered dinner and had a couple of sips of his drink, Barney launched into one story after another, each one better than the last. He began by telling me how he and his friend, Louie Alvarez, liked to walk out to a favorite meadow, near Grass Valley I believe, sit and sip whiskey, and talk about science. "Have you ever noticed how the Tree of Life looks like it has been trimmed periodically by a Japanese gardener?" he asked me. "Well, er, no." I responded truthfully.

So he fills me in on the great extinctions that have occurred over the past 570 million or so years, the greatest of which is the demise of the great dinosaurs. "The other day Louie told me that he and his son, Walter, have figured out what wiped out the dinosaurs." What followed was a very interesting and convincing description of the meteorite impact theory that would not even be published until perhaps six months later. I learned about the iridium-laced clay layer that is found precisely at the K-T boundary all over the planet, and how this is the smoking gun that proves that an extraterrestrial event must have caused that extinction.

While I was still trying to wrap my head around this intellectual blockbuster, Barney launched into the next tale. I believe I must have been an OK audience, because his level of enthusiasm was definitely a notch or two higher by now. In this one, the scenario moved to Brazil. Barney was there on a business trip, apparently alone. While having a drink in the hotel bar, he struck up a conversation with the bartender. Somehow the conversation touched on petrochemicals and fuel shortages, and the bartender informed Barney, "That's not a problem here. The farmers just tap the local trees and burn the sap in their diesel tractors." He had a bottle of this liquid behind the bar that he showed to Barney. Barney asked how he might talk to a local farmer and see some of these trees, and the bartender gave him directions.

The next day Barney drove out to the local farm and met the owner. This fellow showed Barney how he tapped the trees, removed a bucket full of the sap, carried it over to his tractor and poured it into the fuel tank. The sap is called copaiba (coh-pah-eeba) oil and the tree is commonly referred to as the Diesel Tree (officially Copaifera Langsdorffi).

Next Barney described the research he had done on these trees, the conditions required for their growth, and the yields of oil per acre. His calculations indicated that this resource had the potential to replace the current oil industry, as we know it, with a carbon friendly and sustainable alternative.

I wish I could remember the third tall science tale that Barney spun for me that evening, but that one remains buried under the 35 years of stuff that overlays it now in my brain. All I can remember is that it was just as far afield and outlandish as these other two. So much so, that I got a little suspicious. "Barney, these all sound like the scientific equivalent of 'shaggy dog' stories. Have you just been pulling my leg all evening to see how much wool you can pull over my eyes?"

"Oh no!" says Barney, with a look of innocent and sincere concern on his face. "I swear, these are all true stories." I was convinced then but, when the Alvarez discovery was published several months later, I had to smile. Barney had indeed been telling me the absolute truth.

A Breakthrough in the Lab Prototype Phase

From here, development of the HP 7580A proceeded fairly smoothly throughout the lab prototype phase. By now the prototypes looked very much like the final product depicted here. The elegant industrial design, created by Bart Davis, took full advantage of the unique paper drive mechanism and resulted in a large format plotter that took minimal floor space, and was easily rolled from place to place on castors.

For readers who would like more detail on individual development team efforts, it can be found in the November, 1981 issue of the HP Journal.

As is typical on an R&D project in the development phase, one engineer or another would come forward about once a week with an idea for a new feature that we could include in the final product. Usually I would appreciate their idea but suggest that we put it on the shelf until the "B" model entered development. By then we would have some market feedback that would help us decide which new features would best address unmet customer needs.

One day, though, George Lynch, now the project manager, came into my office with Dave Perach, one of our mechanical engineers, in tow. "Dave has invented a way to cap liquid ink pens and keep them wet and ready to write for up to three weeks." George announced. Dave was famous among our engineering staff as being the guy who never sent a rough sketch to the model shop. Everything he designed was delivered as a flawless India ink drawing. Hating to waste time unclogging and cleaning liquid ink pens, he had launched his own side project to find a way to effectively cap these pens. After trying many different kinds of rubber, he had found one that effectively sealed in the solvents in liquid ink, and kept the pens from drying up.

Remembering the plight of the architect in Bath, England, I enthusiastically gave a green light to including this invention in our first release.

Disaster Strikes in Environmental Testing

Once the lab prototype design stabilized and the machine proved capable of creating visually flawless drawings, we moved into production prototype phase and built several machines that were used for various purposes; environmental tests, manual writing, and marketing efforts, to name a few. Work progressed smoothly and according to schedule until disaster struck during environmental testing. A machine had been set up to run continuously overnight in low temperature and humidity conditions. When the technician arrived the next morning, the plotter was sitting there motionless with a completely destroyed D-size drawing wadded up and jammed in the paper-moving mechanism. No cause of this event could be discerned. When cleared of the jam, the plotter once again worked perfectly.

Further tests were done under similar conditions, this time using several prototype plotters in the chamber, and a technician watched through the window with orders to never take his eyes off of those machines. Sure enough the jam happened again, but the observer claimed that it happened so fast he couldn't even begin to explain the cause.

For a time we were in a quandary as to how to diagnose this failure mode. Then someone discovered a new, high-speed video camera that could run a 30 second tape loop over and over until triggered to stop. We rented one of these instruments, and eventually were able to record the failure in slow motion. The paper moved freely back and forth through the mechanism, until one cycle where the paper extended normally out in front of the plotter and then, in a few milliseconds, swung down and plastered itself tightly to the metal platen and the legs of the plotter. The grit wheels couldn't pull it loose and simply tore holes in the paper. Then after a short while the paper freed itself, and began to move again. By this time, though, it was no longer properly aligned with the paper path so, as it passed through, it simply wadded up and jammed. Static electricity build-up was the culprit.

A redesign of the platen surface on which the plotting medium moved solved the problem. A textured coating of carbon impregnated Teflon reduced contact area and friction, and it bled away surface charge before it could build up. In addition, the surfaces of the platen skirts hanging down in front and in back of the platter were dimpled outward to ensure that the area of any contact with the plotting medium would be minimal.

The good news is that we found this problem during product verification testing on a few prototype machines, instead of letting the customer discover it for us. Had this been the case, not only would we have created some very dissatisfied customers, we would have had to retrofit several hundred machines out in the field.

A Spectacular Success at Introduction

In January 1981, San Diego Division introduced not only the HP 7580A plotter for $15,450, but also a complete line of drafting supplies that HP was prepared to ship. This happy event, though, quickly became a good news-bad news story. The good news was that plotter sales took off like a rocket. They were at a rate that was five times greater than our marketing people had forecast. The bad news was that some of our key vendors were not prepared for such volume, and struggled to ramp up their capacity to meet the demand. Order delivery times extended out to 4 and 5 months before our supply chain finally caught up with the order rate.

Shortly after the product was introduced, the HP sales people in Phoenix approached Frank Lloyd Wright's operation at Taliesin West in Scottsdale. Having never been able to get a foot in the door of this place before, folks there were very receptive to HP this time when promised a demonstration of this new plotter, and a presentation by some of the people who developed it.

We removed the legs from the one of our prototype plotters and loaded it into the back of my airplane. Then Bart Davis and I, along with a couple of engineers from the project flew to the Phoenix Sky Harbor airport where a cadre of very appreciative HP sales people met us.

The show at Taliesin West was a great success, and we all enjoyed a guided tour of the place before we departed. The HP sales team insisted on treating us to an early dinner before our departure and, while at table, the sales manager mentioned, "Boy, I sure wish I could get my hands on that prototype for a few days. I could sell a pot full of those things."

|

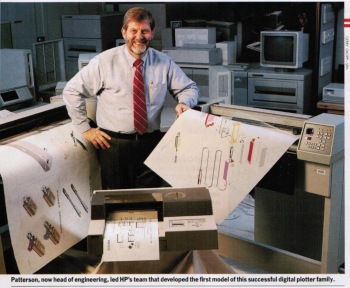

Not many HP products get special coverage in Fortune Magazine. Photo courtesy of Fortune Magazine. |

I said, "Well, it's Wednesday and I don't need this prototype back at work until next Tuesday. Would you be willing to drive it back to San Diego for me, and maybe make a few stops along the way?"

"That's a deal!" he said.

When he dropped our plotter off in San Diego the next week, he said that literally everyone he showed it to bought at least one. I asked him if, by any chance, he had stopped by that construction site we had visited a couple of years before. "I sure did," he responded, "and that guy we talked to bought one on the spot."

"I guess it must be worth more than that new pickup truck." I observed.

An Unexpected Bonus

In spring of 1981 I received a call from a UCLA mechanical engineering student we had employed the previous summer to help with product verification tests on the HP 7580A. His request: Would we be able and willing to bring one of our plotters up to UCLA, show off its performance, and give a talk about its development? Seeing this as a great opportunity to get budding young engineers interested in HP, we jumped at the chance. Once again we loaded the plotter in the back of my airplane and headed out, this time up to Santa Monica.

The talk went well and, before we all went off to lunch, our graduate student introduced me to his advisor, Professor Ross Allen. He then gave Dr. Allen a demonstration of the plotter he had worked with in his summer job. These demonstrations were easy to do by; 1) loading a piece of paper in the plotter, and then 2) holding a button down on the back of the plotter while turning the power switch on. A line quality test program then would play automatically for several minutes, filling the paper with a series of difficult line quality exercises designed to reveal any flaws in performance.

When we got back from lunch an hour or so later Dr. Allen was still there, standing by the plotter, watching it perform. The little office was filled with test plots he had run again and again.

A couple of weeks later I received a call from Dr. Allen. He was going to be in San Diego and wondered if we could have lunch together. When we met for lunch he informed me that he really wanted to come to work for HP. He wanted to invest his career in a company that could create such beautiful machines as that plotter. I informed him that we were not hiring at the time, but I would be very happy to meet with him again when that changed.

To make a long story short, we had several lunches over a period of several months. At one he gave me a stack of journal articles about 6 inches high that he had published. After I read them I went to Tom Vos, our R&D manager. "Tom, this guy is really brilliant, and he won't go away. We have a hiring freeze on. What should I do?"

"Bring him in for an interview," said Tom. We did, and everyone who spoke with him both liked him a lot, and found that, technically speaking, he walked on water. Tom's response to this outcome; "Make him an offer. Forgiveness is a lot easier to get than permission."

Ross thus started his long HP career in San Diego working on almost every aspect of HP Thermal Inkjet. In '89, he moved to HP Labs and expanded his work into digital imaging. Ross and his team invented the technology used in the optical mouse and the optical media advance sensor. This technology makes high output quality possible in HP's large format inkjet printers, whose heritage traces directly back to the HP 7580A. This sensor closes the loop between a servomotor, which drives the paper with grit wheels, and actual motion of the paper surface. He retired from HP in 2002 and has been a contract employee ever since. He is known as "the Voice of HP inkjet", and travels the world explaining the technology inside new HP printing products.

In an important way, the good work of the HP 7580A development team was instrumental in bringing in key talent that made HP's success in inkjet products possible.

Epilogue on the HP 7580A Development

In the spring of 2013 I was doing booth duty at our Los Altos Rotary Club "Fine Art in the Park" event when an old couple (about my age) walked by. The fellow struck up a conversation that eventually turned to careers from which we each had retired. When he learned that I had spent 20 years in HP R&D he immediately asked, "What products did you do?"

|

The HP 7580A development team celebrating the first unit off of the assembly line in 1981 |

When I mentioned the HP 7580A, his wife spoke up, "Oh, he has two of those in our basement, and he's down there running them all day long, every day! He LOVES those things!"

He bought them for his company in the mid-1980s, and then took them home when he retired. Those machines have worked hard and flawlessly for more than 20 years, and are still delighting the customer.

To the HP 7580A development team: My hat's off to you. You did damn fine work!

5. Master

Once the Big Bertha project was finished I was poised to immediately get going on the HP 7585A, a 36" wide version of the HP 7580A. Tom Vos, though, surprised me and assigned that project to another section manager. His assignment for me was, "Marv, you spend some time figuring out what's next in graphics." This gave me an opportunity to think about visual information from a more global perspective and, once I did, the future of plotters drawing lines on a plotting surface began to seem pretty limited. The digital world was moving ever faster toward raster graphics, and away from line drawings. The future seemed to belong to toner and inkjet printing and imaging products.

I investigated the complete range of printing technologies; all the way from the most elegant color lithography techniques, all the way down to the grubby color images printed in the Comics section of the Sunday newspaper. My goal was to identify the fundamentals that defined image quality. The result that I derived was that image quality is determined by the amount of discernible information per unit area. This, in turn, depends on; 1) the density of pixels in the image, 2) the level of quantization applied in the imaging process, 3) the number of colors used to create each pixel, 4) the acuity of the human visual system to each of these colors, and 5) the signal-to-noise ratio inherent to the imaging medium. I wrote an article describing these findings, "An Analysis of Visual Communication Based on Electrical Signal Theory," in 1985 and circulated it widely to relevant R&D labs in within HP. In 1986, it was published the Proceeding of the Society for Information Display (SID).

HP Corporate Engineering

In the summer of 1985, I relocated to the San Francisco Bay area and joined the Corporate Engineering (CE) department. My first noteworthy accomplishment was an article published in the Feb/Mar/Apr 1986 issue of the R&D Network magazine that questioned whether or not MBWA (Managing by Wandering Around) was still part of the HP Way. HP's CEO, John Young, didn't like it at all, and sent our director, Chuck House, a note to that effect. I did, though, get some positive feedback from the rank and file from around the company so I guess there was some merit to the article. Once again, though, my inclination toward political incorrectness had reared its ugly head.

In those days CE was trying to get its arms around the idea of R&D productivity, what that might mean, and how CE might have a positive impact on it. At an early division review, probably 1986, Chuck was on stage presenting our programs. When he mentioned "R&D Productivity" someone in the audience immediately asked, "What does that mean anyway?" Someone else spoke up, "Yeah, how do you measure that? In fact, who in your group is in charge of R&D metrics?" Chuck didn't even take time to blink. He said very matter-of-factly, "Marv Patterson." And that was exactly when and how I became responsible for R&D metrics.

After that review I scrambled to put something sensible together, but mostly I just thought about everything that moved versus time in an R&D department, and then made up a way to measure it. In those days we had relationships with a couple of productivity consultants, W. B. Werther and W. M. Ruch, who had written a book, Productivity Through People. When I showed them my list of metrics, their one question highlighted my shortcomings for this assignment, "Good grief! What kind of behavior are you trying to create with these?" Bill Hewlett himself once said, "Tell me how I'm going to be measured, and I'll tell you how I'm going to behave." So I went back to square one, and began to think about desired R&D behaviors.

A de facto team formed to help answer this question that included Charlie Elman, Tony Fanning, Steve Joseph and myself. We soon realized that the work going on in the many HP R&D labs around the world was so diverse that no single set of desired behaviors would work. What did emerge out of this work, though, was a unifying role that Corporate Engineering could play to help HP get a greater return on its worldwide investment in R&D efforts. Stated in simple terms our mission relative to HP's engineering community was to: Review, Connect, and Improve.

Review

HP's R&D labs tended to be both geographically and organizationally isolated from one another. A common complaint one heard among our corporate leaders was that, "If HP only knew what HP knows, we'd be a much greater company." The solutions to sticky engineering problems were often invented multiple times around HP. The one channel that worked well in spreading the word about good engineering going on around the company was the HP Journal that was published monthly. In general, most engineers would read it cover-to-cover when it arrived. But only a small fraction of the excellent engineering happening in HP ever got published in the Journal.

Corporate Engineering personnel were well positioned to be familiar with the bigger picture of what engineering teams were working on throughout the company. We routinely visited each R&D lab on other business several times a year. If these visits were properly executed and managed we could compile a broader understanding of common issues and obstacles, training requirements, and computer-aided engineering needs around the company. The opportunity for highly leveraged, company-wide solutions was substantial.

Connect

Information gathered during these reviews would also provide a broader understanding of what challenges each engineering team was addressing in each R&D lab. If managed effectively we could be instrumental in connecting people with tough problems to solve with others in the company who possessed relevant experience and knowledge. In effect we would be helping engineers around the company "know what HP knows."

Improve

Finally, the information gathered through our ongoing contact with HP's diverse engineering community would, in essence, serve as a continuous stream of incoming knowledge that would allow us to discern the most important opportunities to improve HP's overall engineering effectiveness, and then develop and deliver the training and services required to realize these advances.

A Change in Leadership

About the time we formulated this vision for Corporate Engineering, the company decided to create a new division focused on creating solutions specifically aimed at software development issues, particularly those that HP faced. They chose our director, Chuck House, to lead this new effort, and gave him license to include in this new organization roughly half of the people in Corporate Engineering. Chuck and those of us on his staff met to discuss this reorganization, and collectively decided on those parts of CE that would go with Chuck and those which should remain in place.

Those of us who were to remain in Corporate Engineering operated without a leader for a short time. Then one day we learned that somehow our Software Quality and Productivity Assessment (SQPA) group had left to join Chuck's organization. They were certainly fine people, and I could see how they would do that effort a lot of good. We had, however, clearly identified them as belonging solidly within CE's charter.

In response to this news I penned a memo to Lew Platt, who was responsible for CE at that time, and requested that he assign an acting CE director soon who could protect the organization's remaining resources. This was in December 1987 and, at a Christmas party at Chuck's house we both attended, Lew asked me to take on that role until he could find a suitable replacement for Chuck.

He and I met again in early January; the first of what would become weekly meetings. I described for him our Review, Connect and Improve strategy, and he thought it made a lot of sense. Then I asked him to consider me as a candidate for the position of director. He was very clear on my possibilities, "Marv, you are doing me a terrific favor by stepping up when I need the help, but I don't want you to be rewarded with certain disappointment. You are only an R&D section manager, and don't have the clout or stature in the company necessary to be considered for this appointment."

I thanked him for being straight with me, and then I made a prediction. I told him that, in my view, anyone who had that level of stature would view this job as a step downward. It was a "Corporate" job and that carried a stigma in HP. Furthermore, when the reorganization was completed, the group would only employ about 60 people. For the level of person he was seeking, this would also seem like a step down. And finally, CE's reputation in recent history had not been the greatest in the company. That would make the directorship position even less desirable. I predicted that he would go all the way through his list of candidates and come up empty-handed.

Then I asked him if I could proceed with reorganizing the department around this new charter. I told him that I believed this was what HP needed Corporate Engineering to be, and anything I could accomplish before my new boss arrived would put us that much ahead of the game. He gave me free reign to go forward with this plan.

I closed with, "And please remember, I want this job. I think it's really important work."

Building a new Corporate Engineering