One of our main objectives in starting this website five years ago was (and still is today) to get in touch with people who have worked at HP from the birth of the company up to today. We are interested in hearing your memories no matter what division or country you worked in, or whether you were in engineering, marketing, finance, administration, or worked in a factory. This is because all of you have contributed to the story of this unique and successful enterprise.

Your memories are a treasure for this website. While product and technology are our main concern, other writings related to the company life are highly welcome, as far as they stay inside the HP Way guidelines.

The contributions made by David S. Cochran during his career at HP are illustrated in this chapter. This chapter is a good example of the type of memories we would like to present on this website.

Many thanks Dave for this highly valuable contribution.

Anybody Else ? Please get in touch using the Contact US form.

A Quarter Century at HPDavid S. Cochran ForewordAs evolution has developed, it seems that human talents are distributed in a manner that is uneven and perhaps even unfair. Some seem predestined to be good, better or best athletes. In the Arts, some brains are wired for sound and music, patterns, color, style and form. And for Math and Science, many are attracted to the numbers, complexity, correlations, equations, and the challenging functions of our physical universe. Dave Cochran is one of those Math and Science talents who SEES THROUGH algorithms. He THINKS in algorithms. And we should all be grateful that he ended up in Barney Oliver's R&D Lab at HP. Looking back, it was logical that he should end up at HP; born in Palo Alto, with service in the U.S. Navy just 30 miles north at Treasure Island, and with a brother already enrolled at Stanford, leading to his own schooling there. Dave's early projects were the typical stuff of HP engineers, starting as a part-time test technician while at Stanford, then designing an audio oscillator and a couple of digital voltmeters. I first met Dave when he was assigned to adapt the tunable HP 204B audio oscillator for a special push-button version for Western Electric. WECO had determined that their test technicians could save considerable time by not having to tweak a dial setting thousands of times during their tests. But Dave's lasting contributions to Hewlett-Packard really started with the first scientific desktop calculator, the HP 9100A. Barney's lab was the only place to center the development of this revolutionary new product since all of the divisions of the time were instruments only. The story of how HP married several outside suggestions into a coherent project strategy, all the time working on computer functions such as ROMs (read-only-memory) which weren't developed yet, no integrated circuits, etc, were impressive and challenging. A unique 16-layer printed circuit board was just one of the innovations, which of course would later be done easily on a small silicon chip. The HP 9100A became the stuff of history. But Bill Hewlett kept nagging Barney and Dave to shrink the functions of the 9100A so it would fit in his shirt pocket, unlikely as that seemed. But those technology days of the late 1960s/early 1970s were fermenting with integrated circuits, light emitting diode digits only 1/10 inch high, and the personal visions of that HP Labs team of geniuses. The HP-35 scientific pocket calculator is well recorded as a unique product of science and technology history. But Dave was there, on the inside of the project, and his HP Memory here is full of interesting stories of the various challenges that they faced and conquered.

John Minck

|

Editor Note:Looking backward from 2015, at some creative diversity recruiting practices of the 1970's Many of us lab engineers were privileged to serve on recruiting teams, whose objective was to supply the hundreds of new engineers that HP needed each year to maintain its typical average growth of 15% per year. It was well organized, and offered the recruiters the chance to return to college campuses, motivate those engineering students, acquaint them with HP products (even if we didn't hire a particular engineer, he or she was bound to become a good HP customer when he joined other companies.) This was not a trivial matter, imagine getting turned down by HP, and a year later, working for an aerospace company, responsible for large equipment purchases, the local HP field engineer being told that the new buyer was once turned down for a job at HP! Click here for the story of our recruiting adventures |

Editor Note:Dave Cochran died Oct 7, 2022 ---One of HP's most creative engineers died in Medford, Oregon at age 91. Dave's career of invention is probably best symbolized with the HP-35, the 1972 electronic slide rule blockbuster, which was made to fit in Bill Hewlett's pocket. Dave was one of those Math and Science talents who SEES THROUGH algorithms. Looking back, it was logical that he should end up at HP; born in Palo Alto, with service in the U.S. Navy just 30 miles north at Treasure Island, and with a brother already enrolled at Stanford, leading to his own schooling there. Dave's early projects were the typical stuff of HP engineers, starting as a part-time test technician while at Stanford, then designing a transistorized audio oscillator and a couple of digital voltmeters. But Dave's lasting contributions to Hewlett-Packard really started with the first scientific desktop calculator, the HP 9100A. The story of how HP married several outside suggestions into a coherent project strategy, all the time working on computer functions such as ROMs (read-only-memory) which weren't developed yet, no integrated circuits, etc, were impressive and challenging. The HP-35 scientific pocket calculator is well recorded as a unique product of science and technology history. Dave was there, on the inside of the project, and his HPMemior here is full of interesting stories of the various challenges that they faced and conquered. When the Bay Area Rapid Transit (BART) system started construction in 1964, in one of their early rolling tests, one of the test trains didn't stop on command at the end of the line, plowing into a pile of sand at 25 mph, with no passengers. HP's Jack Beckett, was Chairman of the Metropolitan Transit Commission, with oversight responsibility for BART. Jack's Board determined that an outside technical review was needed, and assigned that job to Barney's R&D lab, which put Dave on that team. Out of the Oliver commission came a "Logic Back-up Train Detection System" based on the fact that trains cannot appear or disappear from the track. This HP-2116 computer system monitored the BART control computer and in all its decades, no two trains have ever collided. With HP's massive college recruitment strategy, Dave pioneered the emerging policy of increasing diversity in hiring. He was assigned to recruit at the University of New Mexico to seek Native American and Hispanic candidates. He soon added New Mexico State in Las Cruces, New Mexico Institute of Mining and Technology in Socorro, and the University of West Texas in El Paso. Not surprisingly he was asked to join several of their Boards, to bring his technology knowledge to their classrooms. He went on, after leaving HP, to work at several hard disk manufacturers, as they pushed the physical limits of laying down microscopic 0's and 1's on a spinning shiny disk and store Terabytes. These tidbits hopefully illustrate Dave's inventive genius, which wasn't constrained to any one discipline. He solved thermal issues, electronic issues, mechanical contrivances, solid-state physics problems, and more-before moving on in other pursuits, including serving on many university advisory teams. The world was all the better for this man's pursuits and accomplishments. His personal story which follows will reveal his unique technical skills as well as his enjoyable personality. |

Excerpted in part from an interview of November 19, 2010.

CHM Reference number: X5992.2011

© 2010 Computer History Museum

|

The Mountain View Computer History Museum, CA features an extensive hardware collection and a comprehensive historical archive |

This HP Memory has been adapted from material I furnished to the Computer History Museum in Mountain View, CA, as an interview. The CHM owns the copyright, and it is used with their permission.

The Computer History Museum has put together a computing timeline, 2,000 years of history starting with the abacus. The HP-35 has been suggested to be one of the seminal products of American ingenuity, perhaps, in all of computing history. And since I was a central figure in the development of the HP-35, I offer this HP Memoir as a record of my career time at HP, a Quarter Century of interesting challenges.

This memoir will cover how did I get into engineering, particularly electronics, why I joined HP, and a couple of the projects that led up to starting the HP-35 development?

I'd known about Hewlett Packard Company for some time, moved to Palo Alto from San Francisco in the second grade. I had actually driven David Packard's car. I don't know if he knew it at the time, but he had donated his car to get out the school board vote and loaned it to my father who said, "Hey, do you want to drive?" At 15? "Hey, yeah, sure." So my father was on the loudspeaker and I drove. And then about a year or so later, I was working during the summer, on a construction crew as a laborer and spent a couple of days assigned to work on David Packard's house. It was his first move, I think, from Addison Avenue and moving up to Los Altos Hills to the Taaffe Address .

Hewlett Packard Company was pretty well known and so I thought, "Well, gee, if I needed a job, maybe work part time there while going to Stanford or something like that." In 1950 I had been accepted at Stanford but then the Korean War started. I said, "Hey, this is my chance. I missed the big one." So I joined the Navy. When I took the exam at the recruiting station, they said, "Oh, you did pretty good in electronics. Do you want to go into electronics? Do you want to go to electronics school? You want to be an ET?" And I said, "No, what's that?" They said, "Well, that's where you fix radios and stuff like that." And I said, "Well, gee, I had difficulty getting my crystal set working when I was a boy scout." But they said, "Well, it's nine months' duty here at Treasure Island, 30 miles from your home." I said, "Okay, I'm in."

And up till that time, I had been very interested in mechanical things, particularly cars. I had rebuilt a '29 Chevy, my first car, and I learned a lot. But I really enjoyed working on mechanical [things]. And then after going to the naval school, then I got very interested in electromechanical [things] and then when I got out of the Navy and started Stanford again in 1955. I started from scratch, but I already had a leg up in electronics, so I said "electrical engineering." They gave me some advanced credit and I combined my mechanical interests with the electronics and what I'd learned in the Navy and four years of training and actual practice. But at the end of the first year, I'd run out of money. I already had a family by then, and so my hat in my hand, I went over to Hewlett Packard Company. It was down on lower Page Mill Road, 395 Page Mill Road, right across from the railroad tracks as I remember. The old saw-tooth building, I applied there for a summer job, got hired. It was then about a couple of hundred employees, maybe 300 or 400.

|

The HP 300A |

I started out on a production line, testing wave analyzers, the 300A. Hewlett Packard, at that time, they were the most ethical company, already had a tremendous reputation, and we were doing hand-calibrated dials. They didn't just stamp them out and put them on and try to tune them up. You hand calibrated all of the fiduciary marks for each of the frequency settings. We would tune a frequency, do a pencil line, tune another and do a pencil line, tune another. We'd put the serial number of the equipment on the backside, and then send those dials to the engraving shop, which would then put on the straight lines. Every dial on that 300A wave analyzer was independently calibrated.

The wave analyzer actually had Hewlett's oscillator design in it. The impact didn't really hit me at the time, but it did later when I tried to transistorize his oscillator in the 204B.

I was in the right place at the right time. I worked that first summer, but then I was going to go back to school. I asked my boss, "Is there a way that you can let me work half-time?" And Hewlett Packard, even in the early days, it was kind of a mom and pop shop. I forget who I asked, Ray Demere I think, but they said, "Oh yeah. We can schedule the work so that you just work and do this type of production; the rate of that production seems to fit a half-time schedule." And I'd draw half-time pay, so that was fine. So they accommodated the individual. The value of the individual at Hewlett Packard was important to them personally.

My younger brother had already been at Stanford for a couple of years, helped me plan out my program so that I took all of my labs my first year. Actually, my third quarter, I took sophomore courses in my prerequisites for engineering, so at the end of my first year, I had more than 60 units of credit. I only needed 180 to graduate. I averaged 20 units per quarter. I had to get special permission, but from then on, I only had to go to school in the mornings, so now I had the afternoons free and I would work from 1:00 to 5:00 PM. So four hours just fit, and it was perfect. Then after three or four months, somebody in the lab --and it was just one laboratory at the time-- had recognized my work, or walked into production and seen me, knew I was working towards my degree in electrical engineering, and asked if I wanted to be a lab technician, kind of a junior engineer in the lab. Boy yeah, sure. Why not?

Bruce Wholey and Ralph Lee were involved, and so was Jack Petrak. I was assigned to Ted Anderson but that's another story. Actually, there was a new fellow also, joined the lab about the same time I did as a junior engineer to, and that was Len Cutler. I think by that time he was getting his advanced degree, but he could only work part-time. I was assigned to a digital voltmeter project; the 405 digital voltmeter. It didn't sell very well; looking back I believe the design architecture was probably antiquated-- there wasn't a "gotcha." There wasn't a step forward in that project. But it did train me for later, doing the 3440, which was the fastest seller in the west, or world-wide for that matter.

Because I learned on that first project how to, or how not to design? There is an easy way to design. You just take what's done and make it better, the easy way, and whatever fits. Or there's stretching, and if you reach out, which I will discuss later with the HP-35, on every aspect we reached out. What was the hardest thing on the HP-35? Everything!

So my first project, at that time we were just feeling our way, and I really didn't understand the concept of 'stretch goals' and so forth. I make the point that HP never succeeded when it didn't stretch. And the company learned relatively early it seemed to me, that stretching was always the way to succeed. But unfortunately, HP learned it and learned it, and learned it.

There would be new people in place; HP was in constant flux. I was there 25 years and it was always a new bunch of people who would come in and re-organize. Unfortunately, Hewlett and Packard, the epitome of their personalities, could not be rubber-stamped into the various divisions. And when they got involved, things did happen. I remember a note, we were doing oscilloscopes then in the saw-tooth building and somebody walked through on a Sunday and wrote a note on an oscilloscope and said, "We're not going to build prototypes you can twist up with one hand."

That was Packard, yes, because when he'd get involved, he would say things or Hewlett too. It was wise to listen, because they could look at something, they were both very, very different. I knew them both personally and I even carpooled occasionally with Hewlett when I lived across the street.

They were both very interesting. Hewlett never really had to work. He was born with a silver spoon in his mouth. His father was head of the Stanford medical school, and they lived in San Francisco. When his father died when Hewlett was about 16 his mother took him to Europe for a year or so, he came back and then started at Stanford, but I understand really struggled because he was dyslexic. But you never knew that when talking to him, because he was an engineer's engineer, and he could look at your work and he could talk to you about it, and you could reason with him. You could tell him why you did things a certain way, quite a bit different than our vice president of R&D, Barney Oliver, who usually spent an hour lecturing to you on first principles on what you should have done.

Dave Packard was just a tremendous guy, a very interesting personality. Packard could walk the length of the building and in half an hour's time, tell you everything that was wrong and tell you what you were doing right. But he could tell you, "Hey, you've got too much inventory, you've got too much work in process, and you've got this or that. This machine is out of tolerance." He would just listen and talk a few minutes to one person, the next and so on.

He had that ability, the business sense, and we got a chance to see the differences when David Packard went off to be deputy secretary of defense under Laird, with Nixon. So he had to divorce himself totally from the company. He came back for a visit, and even though he wasn't involved with the company, he brought an admiral in to visit. It was late at night at the Cupertino Building and we were assembling our first production run of calculators. There was a turn-on problem with the calculator.

One of the problems with semiconductors is you do all this logic and sometimes the circuit doesn't turn on in a right state. You have to design so that the chip performs a "start-up" sequence into the proper state. Our first circuits didn't, so we had to put in a pull up resistor to make sure it would turn on in the right state. We had about 30 of these calculators laid out and I was soldering these resistors inside. Here comes Packard with this admiral, since I'd been in the Navy, I didn't know whether to salute or shake hands. He introduced him to me saying, "This is Dave Cochran. He's the inventor of this new pocket calculator." I felt so humble.

After Packard had been in Washington for a couple of years, the country sunk into a recession and the Hewlett Packard Company fell on hard times. All of a sudden, the company was thinking about going out and borrowing money from the Swiss banks, or floating a bond. Hewlett Packard had never done that. And then sales were slipping, growth was negative and so on. That's when Hewlett grabbed something that should have gone down in history as momentous. He says, "Okay, we've got to cut production by 10 percent." Now one way to do that, lay off 10 percent of the people. Instead, he says, "Hey, everybody's going to take every other Friday off, and we're not going to pay you for that." That's fair, isn't it? "We're going to do that from the board room all the way down."

From my perspective, it was welcomed by all. Nobody had to worry about their job and the belt tightening. For the guy that loses his job, he's got to tighten his belt 100 percent, whereas you take 10 percent, and particularly since Hewlett and other executives were taking the same cut or more, but it was a shared thing. That was the family.

I remember before HP had any health insurance, there was no health insurance when I joined in 1956. One of the fellows got tuberculosis, one of the people on the line. He went to a sanatorium and his paycheck kept being sent to his home. And I believe he's still alive today. Hewlett and Packard's secretary was the head of HR at the time too, Anne Laudell, she was everything. I remember the discussion that Hewlett Packard was going to have a health insurance program; must have been in the late 1950's.

I think Jack Petrak was my boss at the time and said, "Hey, Dave, I'd like you to take the light bulb out of Hewlett's oscillator, and see if you can transistorize it." Because transistors were the coming things, I would use discrete transistors. I remember taking a class in about 1957 from Irwin Wunderman in the basement of the 395 Page Mill Road on semiconductor theory. This wasn't even being taught at Stanford yet.

|

The HP 204B |

But then transistorizing the oscillator; I tried to duplicate the characteristics of Hewlett's light bulb, and the more I researched that and read about it, the more astounded I was that it was so simple, but it was so exactly the functionality required. It would have been hard to have said, "These are the characteristics I want: I want the positive resistance (resistance increases with higher temperature), I want this, I want that," etc. And it all had to work at the amplitude levels of the whole oscillator. And to try to duplicate that, oh, I tried to use different light bulbs, you know, grain of wheat light bulbs and so on, to duplicate that characteristic. I'd like to run some experiments today to see if I could use a light bulb, I know so much more now about experimentation

Finally, I ended up by making some soft diodes that actually performed a clamping action in the feedback loop. And when I say soft diodes, I added resistance to make them-- Discrete resistors on regular diodes and used them as shaping diodes. I had a choice between a hard clamp diode, which would be more stable, but then the wave form on an oscilloscope would be this little tick, a little notch out of it. So I balanced that against the distortion. But I was able to do it, I think with five transistors for the whole thing. I learned a lot on that first product.

I believe creativity is developed, learned by trial and error; I used to tell people, if your circuit works the first time, you didn't learn anything. I remember one poor fellow, he wasn't in the lab very long, and he built this circuit by soldering resistors and transistors and capacitors together. It didn't work, so he pulled out a hammer and just smashed it flat and started all over again, didn't analyze it, didn't learn a thing.

One of the things that I found out was how I drew a circuit schematically was how it might lay out on a printed circuit board. What I had to do, by the time I realized that, the transistor with an emitter, collector, and base in a certain triangle pattern. When you laid out the printed circuit board, you didn't want a connection or trace to have to go between the other legs, because then it might hit one. I turned my circuits upside down with ground at the top and the power supply down at the bottom, just the opposite of a vacuum tube circuit.

I discovered I was a graphical, special thinker, imagining shapes in my mind. Actually, somebody wrote a paper on that, on me. From Princeton, they did a study on my thinking ability after I'd been in a few publications, they wanted to know, if I need to visualize it. So it was along the way that I learned things, not how to invent but stretching, by "I have a goal." The 204B Audio Oscillator, was really good to teach me how to use transistors, how to lay out printed circuit boards. I got involved in every aspect of the design.

|

Two opposing spiral cams convert linear dial motion to non-linear resistance change |

One of the challenges of making a transistorized RC oscillator was to make it smaller than the original one with the large tunable capacitor. HP had a department that made variable resistors; I replaced the tunable capacitor with a variable resistor. At first it looked like the resistor would chatter a little bit as you rotated the slider, producing a variation in the amplitude, but was smoothed out by the amplitude feedback loop.

But the variable resistor was linear, quite dissimilar to the design of a variable capacitor whose capacitance varied nonlinearly due to its shape. Hewlett's oscillator had a fixed R and a variable C. So what we needed to non-linearize the resistor motion. I went to one of the mechanical engineers, Knut Scarpus who said, "Why don't you try an exponential spiral?" and I said, "What's that?" With that he drew an exponential spiral and then he drew another one. He showed me a gear set in a magazine mounted on fixed centers, yet the action was transferred between these two exponential spirals producing the desired non-linear output. We duplicated the exponential spirals without gear teeth, but used a tuner cable of 15 or 20 strands of phosphor-bronze covered with plastic in a "figure 8" configuration. We could wrap it around, so as you moved one spiral in one direction, the other one moved oppositely. The design allowed the use of pre-calibrated dials with a good range of non-linear frequency fiducials within accuracy limits.

It would have been simpler to make the oscillator with a nonlinear dial; that would have been the easy way. However easy usually never leads to a great product or innovation. Furthermore beg, borrow or steal to accomplish your design goals; let the lawyers worry about infringement. The discussion on non-linear rotation led me to research some articles on the subject; well before the era of Google. Yet HP was able to design and produce the exponential spiral toothless gear solution.

Due to the precision and linearity of the variable resistor a pre-stamped dial could be used rather than having to hand calibrate and engrave. To achieve the two per-cent accuracy the calibration would have to be "rocked in" similar to setting up an FM-tuner in the old days. When the 204 was introduced to manufacturing the line leader told me it was too difficult to adjust. He says, "I can't do this." I said, "Look, I took the manual dexterity test here at HP and I'm in the lowest 15 th percentile. And if I can do it, everybody can do it." I shamed him into running it on the production line.

We made a gold plated one and tried to present it to Walt Disney. I think Dave Kirby our Publicist got Hewlett to go down and it was kind of embarrassing; Disney thought it was just a gold plated little mockup, but it was actually a working 204B-designed as a smaller version of original oscillator, but we gold plated it to give to Disney.

During the development I was afraid to show Hewlett what I was doing because I just couldn't use his light bulb. He kind of had a passing interest and he said, "That's fine." Every time I would see him about it, then I would say, "You know, what you did with the light bulb was really terrific and I'm afraid I can't find the transistor equivalent." So I was really with my hat in my hand when I talked to him about it. But he recognized that we were moving to the transistor age.

When Hewlett developed the original oscillator, I think that he was looking for something with a positive resistance characteristic to provide negative feedback for amplitude stability, but I don't know what led him into a light bulb that fat. All I can guess-he knew the characteristics he was looking for.

There was an ancillary story to 204B. That was one of the products that went to Loveland [Colorado]. Loveland was one of the first divisions, and how I met Ray King was, they were having problems with manufacturing the 204B out there. It wasn't meeting the output spec. I had made a transformer that would go convert a single-sided to a floating output, because the transistor circuit required a ground. I had designed the transformer with number of turns and certain thickness of insulation. Ray King was the production engineer on that product. Ray's team decided to make the transformer a little bit cheaper and easier to construct which dropped the capacitance between the windings; making the output not quite symmetrically floating. So I said, "Hey, you can't do this." Again, that was one of those trivial things that I researched and I tried to do the best to meet the requirements, and the requirement was that it have a balanced output.

My next project; it was suggested that we develop a follow on to the 405B digital voltmeter now several years later. There was more technical architecture available. And could we use some of the products that were already coming out of the other divisions? For example, the frequency counters and so on. Don Schultz was the program manager of the 3440. I certainly didn't go to Don Schultz and say, "Hey, I've got some great ideas on digital voltmeters." Chuck Near and I were assigned to it; we did some research, and surveyed up all of the resources that HP had. The design was kind of a top down. They were already working on the Nixie tube displays for transistorized counters in of the frequency and time division.

|

The HP 3440A

|

The biggest challenge for the HP 3440, making a dual-ramp digital voltmeter that would track with time and temperature. There had been some discussion in articles in magazines about the dual-ramp technique, but I needed temperature compensation. I needed those ramps to track each other. I think I'd taken a solid state physics course by that time, at Stanford, where it talked about transistors and it talked about band gap energy and those kinds of things. We mocked the design up with two different diodes and it was just terrible.

Since the design was chosen the technology had to be controlled; I got Horace Overacker in the solid state laboratory to make me a dual diode. I said, "Could you do this?" He said, "Sure." I was the first one that had ever asked him to put two semiconductor elements on the same piece of silicon (maybe it was germanium). It was a diode with two anodes on the same substrate. Wow, an integrated circuit, but it was only diodes. Then we had a reference ramp compared against the input and it really worked very, very well. I used to tell people that I really did an integrated circuit way back. And got it cheaply, it was about two and a half dollars. Now we have a $1,000 four- digit voltmeter and no one else did.

The 3440 had a number of features, with a range up to 1,000 volts. I'd had some experience with low leakage requirements; I earlier designed a selectable, by push button, digital oscillator. I couldn't figure how to get the very high impedance with the pushbutton switches to ensure the low current leakage required. I tried a Teflon insulator but I had never worked with Teflon before. This Teflon insulator was to isolate the switch that you would use to disconnect and connect the [reference] standard an internal standard to calibrate the digital voltmeter. I bought some Teflon washers from a sales rep.

I called him up the next day and I said, "When I tighten these down, then I come back later and find the torque had relaxed to about half of the original value." What I learned was, you decide on your final torque and you tighten it down at something greater (like two times) than that, and then it relaxes to that final torque. Either that or you have to mechanically capture or enclose the whole thing.

In another project I remember immersing switches that contained paper composition printed circuit boards in silicone, silicone fluid. The printed circuit board was made out of special absorbent paper that would absorb the silicone. I could get 1012 resistance. My purpose in citing these issues is that I usually ran up against problems or challenges at every step in the design. Significant designs not easy. If they were easy, I'd say anybody could do it?.

The instrument business had a particular characteristic, wasn't like building radios or televisions. This was pretty much black art. Every box was a new idea and everyone is at the edge of the state of the art. So the problems you have, perforce, aren't in the books. The more successful the product, the further you expressed, I feel, looking back at it.

At HP in field after field, element after element, developed tremendous resourcefulness, a can-do attitude, for whatever comes your way. The original HP laboratories were split into division labs and HP corporate lab, I chose to stay in HP Labs.

Seventy percent of my projects at HP Labs, were successful, meaning they went into production and were profitable for the company. If I couldn't embrace the project, didn't believe in it I either killed it or got off of it. I stayed on ones that I was interested in or believed in.

Occasionally innovation was forced on me; for example on the 3440 was at the prototype stage and was sent it to Heat and Beat (the environmental chambers). It wouldn't work, got too hot when you stacked them. Don Schultz, the program manager, he would get red in the face, like a thermometer when he was upset. He said, "Dave, I told you months ago to check this out. Now here we are, already in our prototype, and the damn thing's not working." And I said, "Okay. Give me a little time to think about how to fix this."

Well, Chuck Near and I looked at this thing, and we had the covers off. We said, "We can't put holes in it because if we put holes in the top cover, the heat from this machine will just heat up the one above. So the only way we can get heat out is through the back, the back panel." And we'd already done one thing unique, and that was, we took the cover off the transformer, bolted the transformer onto the back panel, and put the cover on the outside of the back panel so that the heat transferred.

We thought, "Now how about the rest?" And the number AC-4A rings a bell, I think that was the part number for frequency counters, the stack for each digit with a nixie tube. And I said to Chuck, I said, "You know, if we drill some holes up front here and we get and we take the chassis and cut it short as it doesn't have it go all the way back."

I had taken the thermal dynamics required as sophomore or junior engineering course from Venard at Stanford. I still tell anybody that will listen, "Don't skip the fundamentals!" , material science, fluid dynamics, physics, chemistry. I said, "Okay, where is the heat coming from? It's coming from these array of transistors here. Okay, if we can get that heat coming up to the top and then it'll move towards the back because the back is where things are cool." Without a fan-we'll get natural convection. We immediately tried it--got a 15 degree drop, got it down to 45 degrees. It was tremendous. Because it doesn't take a lot of airflow. And it saved my butt with Don Schulz. We changed the design of the chassis, added a bunch of holes.

|

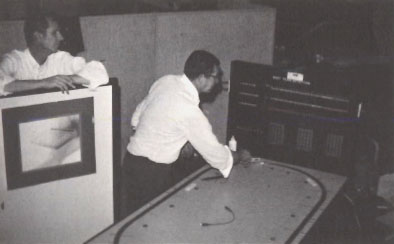

| With Dave Cochran as observer, Len Cutler makes successful first test of the new train-detection system created by HP Labs team for the San Francisco Bay Area Rapid Transit District. Picture from MEASURE Magazine January 1974 Courtesy of the Hewlett-Packard Company |

Barney Oliver's technical expertise was well known to the high-tech community. When the Bay Area Rapid Transit (BART) system started construction in 1964, in one of their early rolling tests, one of the test trains approached the Fremont, end-of-the-line, station. Instead of slowing down, the train speeded up plowing into a pile of sand that some cautious engineer had insisted on providing instead of a hard bumper. Luckily the train was only traveling at about 25 mph, with no passengers.

One of the HP corporate managers, Jack Beckett, had been involved in industrial volunteering for some years, and at the time was Chairman of the Metropolitan Transit Commission for the Bay Area. Their responsibilities included oversight responsibility for BART, and such a serious operating computer failure was potentially catastrophic. It was crucial that the deficiency of the train control system be immediately investigated, so that the rollout of the system could proceed without concern about defective control.

The design for the BART was visionary, with the committee focusing on high tech cars and control technology. In retrospect, it was probably not a good decision, and the committee would have done well to visit Europe where they had for decades built and operated rugged and reliable cars and control systems that were designed for fail-safe performance. Westinghouse was the main contractor chosen for their futuristic control proposal. But there were to be revealed a number of black-holes in their design.

With the support of State Senator Alfred Alquist, Beckett immediately got the Board to appoint a technical study commission, chaired by Barney. What they found was troubling. The objective of the original proposal was to have a system of trains running at up to 90 mph with a 3-5 minute headway (4.5-7.5 miles) between them--without human operators. Geez, there is a design just begging for fatalities. The train control consisted of a radio link between the speeding train and an endless antenna running alongside the tracks. The braking system of every train was controlled by an automated built-in stopping profile determined by the wayside electronic signaling system based on the distance ahead of another train. This "local" train control was augmented by the central computer system (big-daddy) in Oakland.

On the day of the "crash," the train control detected its approach to Fremont station, and sent its signal to the speed control system in the train to call for the beginning of brake action. However the 27 mph crystal had shorted and the speed control system went to a free running oscillator that happened to call for 70 mph. The system had not been designed "fail-safe," i.e. to stop if the correct speed could not be attained. The on-board human operator lunged for the emergency brake, but the few-second hesitation was enough for the train to over-run the station.

The upshot of that revelation resulted in a scathing letter that Barney wrote to the CEO of Westinghouse. In essence, Barney accused the company of dereliction of engineering responsibility and suggested that they must have assigned their poorest engineers to the tasks. Redesign took place immediately. I believe that was the year that Barney had been elected to the presidency of the IEEE, the international society of professional engineers. So his words had extra impact on Westinghouse.

Another system design flaw was discovered in a "phantom" train problem. It seems that Westinghouse did not use the decades-old design practice of train detection, as practiced throughout the world. Instead because of the continuous welded rail to eliminate the clickity-clack, they had to design a monitor which measures the electrical impedance between the two rails by the steel wheels of the car touching both rails. The problem is that Westinghouse didn't count on the nasty environment of the rails, oil, dirt, corrosion and water that meant that the impedance changes weren't always sensed correctly, particularly if a train had lost power.

The urgency of a fix was paramount, since the system was close to coming on line. The upshot to the Oliver study was to quickly design an alternate system to ensure continuous detection. In the interim, human operators at each station would provide input (they would call the up-line station and tell them to release the train) so that the main system operating displays were assured. We used to joke that we were going back to the old-time method of the station agent waving a lantern to let the station up the line release the next train. For a time, a given train could not get a command to leave a given station if an operator at an advanced station had not given proof that the previous train had left a future station.

Out of the Oliver commission came a "Logic Back-up Train Detection System" based on the fact that trains cannot appear or disappear from the track. A simple wayside logic system with each block (minimum detectable length) contains the presence of a train once detected. It cannot be dropped until detection is registered in the successive block. The wayside system daisy chains this all together. If movement of the train is not detected in the next block, the stopping profile remains behind in the original block. This was dubbed SORS (Sequential Occupancy Release System by the BART engineers.

|

The Bay Area Rapid Transit Today |

During the "train detection" study the team had ample resources including a train to run up and down a section of track to monitor signal levels under various environments and operating circunstances. Although some of the ideas floated had extremely low fail-safe levels; discussion with the Public Utilities Commission would only accept a failure rate of zero. This concept was designed by Len Cutler and Dave Cochran solicited by Barney for his commission, a patent was received for the idea with BART granted a royalty free license.

The final upshot of the Oliver Commission was that BART service came up on time, ran for some years with the duplicate control systems and human operators controlling a one station separation. During that period, major redesign including the speed control circuitry of grounding the crystal can to prevent the oscillator from working in case of a short, took place in the entire system control computers, sensors, with the "Logic Back-up System" integrated in a fail safe manner into the central computers. Now, 30 years later, the BART operation has been remarkably free of dangerous crashes and failures, never has one train hit another.

Chuck Near was my sounding board. At one time, Paul Stoft the lab director came by, "How are you guys doing," and so on. Chuck could answer any questions because he had filled up two lab notebooks on the 3440 project; I had two pages. Chuck wrote things down, a really good documenter; it was a super team.

Then for a year or two I worked on various ideas such as the Shaw pulse oximeter that I lent some help to. But I was available at the time when Malcolm McMillan and Tom Osborne came to HP with their various, two different calculator architectures. One was the Athena with the transcendental functions. But it was fixed point. And the other was the floating point four-function machine of Tom Osborne.

Barney Oliver called a bunch of us lab engineers together, about 20 people in the room. And he says, "Bill and I have been talking, and we think that we could combine these two architectures maybe to see if we can make a scientific calculator for engineers." And that was the whole purpose. He says, "HP is not interested in making an adding machine or anything point-of-sale, or any of that kind of stuff." He says, "But, something that is an adjunct to our instrumentation where you can take your reading from your instruments." Now, we weren't talking about connecting it electronically, we were talking about just taking the data entering it and perform scientific calculations; it would be a nice compliment for the rest of our product line.

In Summary: Two guys stumble in the front door--And talk to different people. One guy said, "I can do floating point stuff for arithmetic functions." And the other guy saying, "I can do transcendental functions," and wasn't worried about floating point, "I can do sine, cosine," all that stuff. And Barney and Bill got together and compare notes that could be combined into a box that might be interesting for engineers. And then they in turn, at a coffee break, pulled 20 people in a room and said, "I'd like all of you to consider for the next 30 days look at these schemes and try figure out whether something like this might make sense."

It also meant we could grab 20 people or so, and say, "Hey, I want you to study this for 30 days." Now that's a hell of a slice out of your R and D budget. And the company at the time was $150 million in sales, maybe? Probably had 150 engineers total, they grabbed 20 percent of the R and D staff for a month. Probably 50 percent of HP labs.

As I remember, this was strictly to be a calculator, not a computer which was still in debate whether it should be 8-bit or 16-bit merged with the machine back in Detroit, Sam Irwin. I believe Kay Magleby who had been in HP labs and was also an adjunct professor at Stanford was doing some research on 16-bit machines at Stanford. HP didn't really have a direction at the time as far as the computers go.

We were given 30 days to determine the feasibility to merge these two calculator ideas together; each of us was given different assignments. I had asked what an "algorithm" was and Barney assigned it to me and said "You're going to find out". At the end of 30 days, we were supposed to come back to Barney and Hewlett to give our assessment, could this be done?

I was looking at Osborne's architecture and trying to figure out what an algorithm was. I even flew down to Southern California to talk with Jack Volder who had implemented the transcendental functions in the Athena machine and talked to him for about an hour. He referred me to the original papers by Meggitt where he'd gotten the pseudo division, pseudo multiplication generalized functions.

My job was to determine how many digits and what the operation time was required; what the architecture had to be; how many registers did we need, clock speed, etc? Other people were coming back with their inputs on cathode ray tube display, keyboards [and so on]. Should we use transistors or small-scale integration? There was no large-scale integration, but there was medium-scale integration, MSI which meant maybe 10 transistors in a chip.

We decided we needed a ROM, read-only memory. And I remember Chuck Near and myself going down to a conference in Las Vegas. And we heard the first use ever documented by an IBM engineer Lew Terman, who later became president of the IEEE. His father was Fred Terman, who that introduced Hewlett and Packard. More than forty years later Lew Terman presented the IEEE Historical Milestone Award at Hewlett Packard for the HP-35 to many of the original designers.

Lew Terman presented a paper on IBM architecture and defined the term ROM. He says, "ROM, read-only memory." There were various ideas floating around; GE had a Capacitrix, where you would put a punch card into a static reader, and if there was a punch out, that meant less capacity in that location, because the dielectric of the card wasn't there. I forget the scheme that IBM was using, perhaps something magnetic. Chuck and I came back and then I'm not sure whether Chuck had-- somebody had the idea of doing a printed circuit board in a dynamic scan mode using the coupling between traces to generate "1s" and "0s."

Somebody said, "God, that's crazy as hell." Now you're going to be reading those pulses. I mean, you've got so much high frequencies and electromagnetic coupling flying all over, you're never going to be able to control the electromagnetic [fields] and you'll never see anything on a CRT because the picture will be all jagged all over and it'll look like noise," and so on. If we had stopped there it would have impeded the project, rather than say, "Well, let's evaluate it, let's go and make a mockup and so on and then proceed."

|

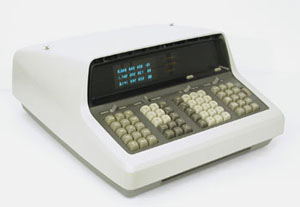

The HP 9100 Scientific Calculator |

The HP 9100 took a myriad of disciplines. It was anticipated that we would have a similar heat problem that I discussed with the 3440 due to all of the circuitry and the CRT display. The designers did something similar. No fan, using a tilted casting with louvers across the front exhausting in the front. Upon completion of the prototype we took it over to try it in Hewlett's desk which had a secretarial slot where he wanted it installed. He wasn't in so his secretary let us in to try it; it didn't fit by about an 1/8 th of an inch. We called the carpenter shop and modified his desk. Hewlett praised the team when he saw it in his desk, if he later found out about the modification, he never let on?

The 9100 used small-scale integration. The printed circuit board ROM technique was all done out of Loveland, 16 layers. We purchased the CRT, as it was a small three inch design although we were making CRTs for the oscilloscope division.

Dick Monnier was the program manager. So my job was the algorithms and working with Tom Osborne to tweak the hardware to make it fit. Because I had never done the algorithms before, so I didn't know how many guard digits. So it took a while to get into the algorithms and to figure out how-I learned a lot.

I did quite a bit of literary research leading to some very interesting discoveries. I learned that the concept of zero was invented in about the 4th century. I found a treatise from 1624 by Henry Briggs discussing the calculation of common logarithms, interestingly used the same pseudo-division/pseudo-multiplication method that MacMillan and Volder used in Athena.

We had purchased a LOCI-2 from Wang Labs and recognized that Wang Labs LOCI II used the same algorithm to do square root as well as log and exponential. After the introduction of the 9100 our legal department got a letter from Wang saying that we had infringed on their patent. And I just sent a note back with the Briggs reference in Latin and it said, "It looks like prior art to me." We never heard another word.

Anyhow after we got the 9100 finished, Willie Kahn a professor up at Berkeley said, "I noticed some bias in your algorithm." I said, "What's that?" He said, "Well, if you do a whole bunch of random numbers, the error does not center around zero. It's about two tenths of a digit off." He wrote a paper about it, I could have said "that's the way the constants come out of ten digit accuracy". I tweaked the constants to have any rounding error center about zero.

Later sometime, I think it probably was on the HP-35, Chris Clare wrote a little book on how to do algorithmic state design and Jim Dooley did some simulation. And he wrote the simulator that we used for the HP-35. And I was trying to think of the state machine concept. I took a course at Stanford from Dave Huffman he taught me a lot about flowcharting; it was logic design, Huffman-Mealy tables, and how to minimize states, and so on. You have to learn the first principles.

HP sales didn't know the market for the 9100 calculator. It wasn't an expensive machine, because we were using for the most part off-the-shelf materials. But remember, HP was vertically integrated with our own die cast shop, we could make the tool for $25,000 and stamp out three a day. A thousand of them would maybe be the total production; if sales increased we could build multiple dies, limited to the cycle time of the die cast molds.

So everything else though was pretty much off the shelf, except for the printed circuit board. But we had a printed circuit board shop. So from the PC shop, and one of the big challenges of the PC shop-- Chuck Near went out and really, he shepherded that. The big challenge was, we didn't know we could get the density. And the challenge was the accuracy of the registration of those layers. You're depending upon the coupling from one level to another across five thousandth of an inch thickness of the board. For ICs, that's nothing. But for fiberglass, that was a big deal.

Then the registration of each of those against each other, and that sandwiching up 16 layers. We did a whole bunch of tests and determined what the requirements needed to be. Chuck Near made it happen at the printed circuit board shop in Loveland. Clyde Coombs later wrote a book on printed circuits and board fabrication. But Loveland really did a very precision job.

The 9100 was transferred to Loveland Division; HP Labs had no manufacturing. The Loveland division was the catch all for audio, video, instruments. This was low frequency, so why not?

After the 9100 I worked on some other things, a companion electrostatic printer. From my perspective, I had always been on the engineering side. But occasionally, I'd go out with a dog and pony show, the sales force. They would pull me in and, "Dave, say a few words about our new product." And I always loved going to Westcon, which was either in Los Angeles or San Francisco in alternate years, and see all the new products.

Aside from that, I just loved the R and D environment. There was some medical instrumentation that Barney asked me about to work on, there were some other things. And my memory of the time when the 9100 hit-- oh, I spent a lot of time up back and forth to Loveland. And I remember having to teach micro-coding to Ed Olander. I taught how to microcode to a number of people, because they said, "Hey, we're going to start the follow-on products to the 9100." It has been said that the 9100 was the first mass-produced "computer" in the history of the world. No one ever built 50 at once.

|

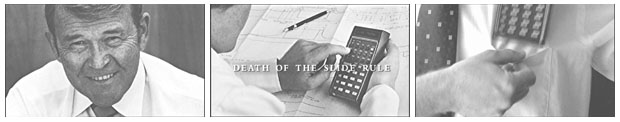

The HP-35: Bill Hewlett's vision for a pocket sliderule |

As soon as the 9100 started showing success in the market place Hewlett started to bug me personally. I know he also talked to Tom Osborne about it, what do you think, and so on. But he would come into the lab and he'd look for me and he'd say, "Hey, how are you coming with putting the 9100 in my shirt pocket?" He said, "I want all that computational power in my shirt pocket."

At first, I said, "Hey, come on. That's crazy. It won't fit." He says, "Dave, integrated circuits are coming and so on." And I said, "I know." I don't think that Moore hadn't even formulated his law at the time in the late '60s.

We were thinking about finding out who his tailor was to see if we could get some custom made for him, with a larger pocket. The HP 35, yeah, it was absolutely all driven by Hewlett. And he was so enthusiastic about it that he had gone to the industrial design department and had them design this calculator before we knew what was going to go inside. He had them design the shape, the key layout.

There was going to be multiplies and divides, there was going to be trig; sine, cosine. Those are all the functions. They took the keys that were on the 9100 and said, "Okay, we need all of these keys, and how to put them on there." And so they spaced them out. And so they had already solved a whole bunch of problems.

Ed Liljenwall and his team solved the roll-over problem, how do you prevent from pressing an adjacent key? And they figured, oh, if we use smaller keys not up next to each other, in other words, separated by space, then you have less chance. And they were starting to sort out which keys should go where. The industrial design or the physical appearance began to take on a shape that Hewlett and the industrial design group envisioned; we never got involved. They were solving problems and determining the shape and so on, and making sure it fit in his pocket before-- it had legs. It was already moving but the pressure was mounting on us in the labs to come up with an architecture. And Hewlett would come by and he'd say, "Hey, industrial design looks really good."

It was a very fortuitous time; Barney Oliver was off working on project SETI, the Search for Extraterrestrial Intelligence. And so he wasn't bugging us about anything.

Hewlett was talking to the light emitting diode group, the LED group, which was a kind of a joint venture between HP Labs and HP Associates. They were already working on a light emitting diode and how to get more light with less power. Because it already had tentative specs; when Hewlett would come and talk to us, he'd say, "Well... this is what I want done." It's got to work a minimum of four hours on batteries. "You're right, Bill. Yeah, we're going to have to find a technology that won't consume too much power." So bipolar was out, it wasn't dense enough. So bipolar used way too much power. So he was already working with those specs. And it had to have the same number of digits we had on the 9100. It was supposed to be a 9100 that fits in your pocket. We weren't going to have three registers, you only need to see the answer.

We had defined some things, the requirements were being formulated, like I said previously, it had legs. It was moving along and people were thinking about it. It was mostly Hewlett, Tom Whitney and I would talk about, well, if we really did this thing what it had to have, and so on. So things were already in there, like battery life, visible in direct sunlight. You had to be able to demonstrate it to somebody, so two people had to look at the display at one time. The light emitting diode group was working with magnifiers. You could use a smaller viewing angle.

The LED group was looking at some driver circuits as well. They talked about things like superlinearity. And I said, "What's superlinearity?" Well, if you double the current, the light output would a little bit more than double. And so you've got a little bit exponential, because there was leakage current. All of those things were going on, and then it happened again, an accident.

Fairchild Semiconductor invited Tom Whitney, I don't know how they sent the invitation, but Tom Whitney and I went down to Fairchild Semiconductor on Ellis Street, Mountain View, and they wanted to show us a calculator architecture that they were planning to provide to various companies that wanted to build calculators and semiconductors. So we went down to look at it. And I looked at it, and oh, this could do the algorithms. See, I knew. By this time, I had already fit the algorithms into a small-scale integrated machine, the 9100. So I knew exactly what architecture I needed, the capabilities of the architecture. I didn't know what it was going to look like, but I knew what its capabilities had to be.

It was I think September of 1970; I saw a design that was different than anything else. It was not your classic computer architecture as taught at the universities. It was all shift register. It was designed for the technology at the time. When talking to the people at Fairchild I me e t a fellow, Rich Whicker, who later came to work at HP. I said, "God, this design, did you think of this?" He says, "No. We got it from Sweda, the cash register company." Sweda at the time was trying to make an electronic cash register or Point-of-Sale products and they were using shift registers.

Shift registers were the densest form of integration of integrated circuits at the time; you had to keep the clock moving and so on. It had no static memory. So here was a design using shift registers a 20-digit chipset that could satisfy anybody making a four-function machine. Add, subtract, multiply, and divide. It could give you the numbers as big as most people wanted, but it was all fixed point. 20 digits should be more than enough for anybody. You could have the decimal point anywhere in that stream.

I got really cranked up about seeing that architecture at Fairchild, I got very excited. And I'm whispering in Tom Whitney's ear, "God, this is great." And I'm trying not to be too excited while I'm there. When we drove away from there and, I said, "God, that's exactly-- you know, I can tweak that architecture just a little bit. We don't need the full 20 digits, we can do this and this and this. And gosh, yes, I can do it, I can do it, I can do it." And so then we started a dialog with Fairchild and then after a couple of weeks, they decided they didn't want to make the calculator chips for HP. They didn't want to modify anything. And it wouldn't fit as it was, because I needed subroutine calls, they didn't have that. I needed really some actually trivial architectural changes, but were significant in order to make the thing work; just changing the structure a little bit. Then I said, "Oh, okay, if they don't want to do that we've got some friends?" AMI whom we'd worked with before and Mostek trying to sell us a bill of goods that they can do really small ROMs, they can do this and that. Why don't we go to them?

Well, that's going to take some money. So then Tom Whitney, Paul Stoft and I went to Hewlett. And I laid out a fleshed out design. I've got the new architecture which I did it in about two weeks, wrote it all out. I have some flow charts with subroutine calls and so on. So I'm really getting excited. So we go to Hewlett. And I said, "Hey, we can do it. We can fit it--" and so on. "Here's the project authorization sheet. Just sign this." He says, "Well..." Now he's starting to second guess himself. He says, "How much is this going to cost?" "Oh, about a million dollars." "Oh." And he's there all alone, Packard's off at Department of Defense.

This is October/November of 1970 and we're on every second Friday off. We're in the middle of a big recession. "It's what you've been asking for two years." Hewlett says, "Well, look, I've got some friends at SRI, and I want to turn it over to them and ask them to do a focus group and do a study and see what we could sell this for. Because it doesn't look like it's going to be under a hundred bucks." I described the architecture, it's going to take five chips and this and that and the three ROMs and such, and LEDs and all of this.

Hewlett says, "Oh, wow. Oh." Actually he wanted the thing, but he never gave it a thought, I don't think, of how much this was going to cost or whether anybody would buy them. He wanted it, remember that he was the next bench engineer. He was the epitome of the next bench engineer. And if the next bench engineer wanted something, you knew it was going to be successful.

Tom Whitney, he was the negotiator. The lab essentially had probably two or three program managers. And he was a program manager with a PhD from Iowa State. Ames, I believe. His role in the project was really whatever was needed on-- I did the architecture and the programming. And he drove the other aspects of it. He was the one that signed up Mostek and AMI. He was the one that would get the machine shop to do special things. It wasn't my chip design. I just took the architecture, I just laid out the high level schematic-requirements; it needed shift registers, but I didn't put the little individual cells in. Francé Rodé and Chung Tung did the individual chip design; they did the detail architecture down at the transistor level and then turned that over to Mostek and AMI, who did the layout. Francé also did part of the bipolar driver too.

One of the things that I've thought about the HP 35, and people have asked how many people were on it? Well Whitney was the orchestra leader, although I'd written the script, he was conducting the whole thing. So then there were the key design aspects of the chips, the keyboard. What was the toughest? There was a myriad of tough things that had to be done. How do we get that feel on a keyboard with no cost? With no space the little oil can feel, the little cricket. It was just some strips that were welded on. But there were a couple of guys, Bill Misson and Don Lobdell who worked on the keyboard. The exact shape of that was a challenge to design to figure out the tolerances.

Whitney was going around talking to this group, "How are coming? What kind of resources do you need, every aspect," whether they were inside the company or outside going to external semiconductor.

After we'd been turned down for our million dollar request we went back to the lab and Stoft said, "Well look, I've got an R&D budget. We'll just start it under our day-to-day lab budget." Stoft figured they'd come back and he'd get it, sooner or later, he'd get reimbursed.

Word started getting out that this was Hewlett's project. So there were about 10 or 12 key people on the thing that were working on it, there was industrial design, a couple of guys there. A couple of guys on the keyboard. There was Francé, Chung and Chu Yen on the DC-to-DC converter power supply.

So now we knew the technology, it was PMOS technology. So now a lot of things were cemented down. We gathered estimates on the power usage, decisions had to be made. It probably took us two weeks to decide on the battery size.

We needed a rechargeable battery, a NiCad, where do we get them from? I even visited the manufacturer to determine the number of recycles we could do, how fast we could recharge the batteries, what the battery life was, could they stretch it, what size, etc.? We settled on AA size, three cells based on the power drain and battery life required. Both bipolar voltage to drive the LED display and PMOS voltages were required for the integrated circuit chips.

We decided to use an inductive driver for the LEDs to store energy and to get the high currents. We had heard that super-linearity would get more light output than just proportional. I talked to the LED guys at HP Associates, "What happens if you pulse these? Can I pulse them with 1,000 amps?" "Oh, no, 1,000? No, no, no." No, we're talking about milliamps." "Oh, well, okay." The average current on the LED segments was something like three or four milliamps. And I said, "Well, suppose we hit them with 30 milliamps, but 10 percent duty cycle?" "Oh, well, that might work." We actually ended up with a one percent duty cycle. Got about three times the light output than we would have if we'd just applied the three milliamps. We put 300 milliamps through it, at one percent duty cycle. Got three times the light output; now that's a freebie.

Somebody asked about reliability. I set up an array of constant current three milliamp displays and compared them to in a set at a 0.1 percent duty cycle, ten times more than our design. I ran those for six months. And then I looked at the comparable light output over time. They were the same. Those were the types of things that would come up. But we had to make the decisions fast and still keeping the constraints of size, the functionality, requirements, etc. There were other things-- one of my fears was doing an arc hyperbolic tangent and having to wait 20 seconds. It was interesting, I had scoped out, I knew how many cycles in the average because I'm doing a pseudo division, pseudo multiplication. It's essentially shifts and adds and so on. How many of those would I be doing?

One of the things that probably is not known is the sine is never calculated directly nor the cosine. There's a secanting error in the algorithm. The algorithm for the trigonometric functions is a little bit more than pseudo-division, pseudo-multiplication. It's a coordinate rotation of the axes, but results in a stretching error, secanting error at each rotation when you rotate it by the arc-tangent of 1.0 or 0.1 or .01, and so on. Its variable, you'd have to keep track of that. I figured if I do just a rotation calculating the sine in one register but the other register is holding the cosine each with the same secanting error. If I divide the sine by the cosine, the exact tangent results to full precision.

The sine is reconstructed by the square root of the tangent divided by the square root of one plus the tangent squared. It was a lot easier than trying to calculate a running secanting error. Secondly, I preserved the small-angle accuracy, because the tangent and the sine approach each other at small angles. See you remember that.

During the HP-35 development every time we faced something that didn't work quite right we attacked it. Some of the challenges were with the algorithms, but the same thing was approached on the DC-to-DC converter or the keyboard field.

The keys in the calculator are not just a little stamp put on top of a key. They are double shot molded, because somebody asked the question "In many calculators, I see that the plus key gets worn off because it gets used more." Well, because they hot stamp. "Well, let's a double-shot mold.", then as it wears, it just goes to the same level you always see it clearly.

It's those kinds of things, they kept approaching it always from what are the requirements and how do we meet those requirements? Not how can we just do the minimum?

There was constant communication. I don't remember formal meetings, but constant. And that's where Tom Whitney was a great leader, "What are the objectives?" Each area was stretched, everything. There were only 10 or 12 key people that were making key decisions and working full time on the project. But then probably another 100 contributed in other departments, machining and the light emitting diode people and the transistor design, the integrated circuit design down in Santa Clara that were making the bipolar drivers. And there were some mistakes made along the way. Some things didn't work quite right and we had to-we were always pushing.

Finally the SRI report comes back; I remember a Mr. Calhoun on the team at SRI. "Well, we did our focus group. They all say if it's going to be a four-function machine, it's got to cost under $100. But what you're planning, we have no idea." We said "Well, we're just continuing on." Hewlett responded, "Well, okay."

In September, we got our first prototypes about eleven months after commencing about six or eight of them, and we were just excited as hell. Oh God we played around with them for about 30 minutes before Hewlett was grabbing them. He was really excited and grabbing them and taking them off to see his buddies. Like Charlie Townes, the Nobel Prize winner in physics, Wolfgang Panofsky, head of SLAC who looked at the thing and says, "Are you going to give this to me?" He didn't want to buy it. There was another Nobel Prize winner at Stanford, Hofstadter, that he showed it to.

Then he showed it to Terman, Fred Terman now provost of Stanford. Fred looks at it saying, "Where's the cable for this? How can you do this? How can you do this?" And he's just beside himself. And then, wouldn't you know it? He presses 90 degrees and hits sine. It blinks at him with an overflow condition. It doesn't give back "10000......" I say, "Oh. Uh-oh." And I knew immediately what I had done. It had divided by zero, I hadn't checked out all of the cardinal points.

I was so interested in finding obscure, random numbers. 90 degrees was not a random number. And so I would do 46.32162 and find the sine of that, and then I would go over to the big red books. It was a National Bureau of Standard tables of mathematical results. I would look up the sine and would check in the 11th and 12th place. I could peek at the extra guard digits and see what the errors were and so forth.

After the prototype we started testing and testing and checking, everything. And we went back for one ROM turn. I had to re-program some of it. Always with programming, you program to fit the size. And so I always had to then to re-program quite a bit, more efficiently to free up additional ROM states.

Hewlett was pleased when we got the final parts in December, 1971. I went up with Hewlett to a presentation at the Fairmont Hotel to show it to the press, there was quite a bit of excitement.

It went into then official production I think January or February. I'm not sure if it was against Hewlett's wishes, but it was optimistically thought, let's do 100,000 buy of sets for the chips for the circuits. There were some sales estimates but all over the place. Mostek and AMI weren't going to crank up their production without a full wafer run, 100,000 sets was only about 50 wafers maybe four inch. We could buy 100,000 die without committing to 100,000 calculators actually.The reason we chose two vendors, AMI and Mostek, was because those of us working on the thing felt that this was really going to be a super deal. We were getting really enthusiastic that we can do this, we could accomplish this. And there was nobody else out there, that we could do it that we were afraid somebody else would find out. And so we split the circuits up. If anybody got a hold of one, they didn't have the complete machine; they never had the complete set. We didn't have any redundancy of suppliers until in volume production when we let both supply all the chips.

I had timed all the most complex functions, it needed to run at a 200 kilohertz clock rate. They questioned specific clock rate but it couldn't be less than that because I needed to complete the most esoteric transcendental function in less than a second. And that's what dictated that. The vendors said, why do you need 200 kilohertz? It's only going to be a four-function machine. And I said, "Oh, we're going to make it do some other things too." We were in bed with Mostek a little bit more because they got to see the ROM. And they were wondering what we--they were doing the ROMs. And so they asked questions and they had an idea that we were doing some fancy calculator. But AMI had no idea.

The 100,000 chip set production lasted only about two months. Sales of the HP-35 really took off. The 9100 desktop calculator was sold through a number of HP channels. When the HP-35 came out, it stood HP on its head. At first, the salesmen got all excited about the hand-held HP-35 when they saw these things. And then they went around to their customers. And the first thing you knew, the salesmen were spending more time taking orders for HP-35s than they were their standard product line.

I remember Jim Treybig tried to explain marketing strategy to Hewlett in the boardroom with a bunch of us in attendance. This was early on, sales were just starting. Jim Treybig is now subscribing to Women's Wear Daily to see how to sell this product through department stores. And he's trying to explain to Hewlett on a big blackboard, I think it was a blackboard at that time, or a whiteboard. And Hewlett, after about 20 minutes, says, "Hey, it looks like a battle plan for World War III. I don't know what you're talking about," and walked out of the room.

Treybig was the short lived marketing manager for the HP-35, he left and started Tandem Computers; then Chuck Comiso took over. Pretty soon it was, "We don't want our salesmen taking orders because it's really detracting from the rest of the HP product line." So next thing you know, it's on the main floor at Macy's. HP is becoming familiar with things they never thought about, what is the "average sales per square foot" at Stanford Shopping Center? On the first floor its $3,000 a year per square foot. The higher you go in the floor level the less the "sales per square foot".

The salesmen were really excited about selling it. The HP-35, it was better at a party than playing a piano. If there was piano player at a party, everybody would cluster around him. Well, if a guy had an HP-35, all the men would cluster around and the women are standing off somewhere saying, "What are those guys looking at?" The word of mouth and the ability to do calculations that previously required a desktop calculator in your office. But now you could do real ones. Hey now as you walk along and think of a question, "Well, what's the gusset thickness on this bridge across a river in Minnesota?" Maybe if they'd had an HP calculator at the time, it wouldn't have fallen down.

|

The HP-35 became Bill's passion, in spite of a |

You could complete or modify your designs, taking the place of slide rules, but set the decimal point over two hundred decades and with greater accuracy. Dietzgen went out of business in about a year. K&E, Keuffel & Esser, maker of slide rules survived because it had the paper business and other things too. You were able to do the exact calculation that you wanted and not have to estimate the power of ten like a slide rule and with ten digit precision.

The 100,000 production order, which at minimum was supposed to last six months, only lasted two months. And another order was placed. Some months later TI started selling a competitor product but had an "equals" key similar to the four-function products but were difficult to calculated equations. The Stanford bookstore started selling t-shirts for $395 that said, "Enter is greater than equals," and they throw in an HP calculator, you see. Remember the HP-35 used RPN, Reverse Polish Notation requiring fewer key strokes to compute complex calculations by using the "Enter" key as a delimiter.

HP-35 overall sales were something around more than 400,000 units lifetime including the replacement, the HP-45 and the follow-ons. We were building a machine specific, with never a thought about an extension for it or greater capability. It had a store and recall, but it had no programming or anything like that. But then as soon as we got that out, then there were other, you know, people would say, "Oh, gee. Can we put a clock in it?".

I'd like to do financial calculations?" "Oh, how many years would you like to--" "Well, could we start at the birth of Christ and maybe go out another 4,000 years or 2,000 years?" And we did that. It goes to the year 4096. None of this stuff where the Y2K, where nothing would work after the year 2000. I wanted it to last at least my lifetime, never know what medical science might come up with. We wanted to know where the business days fall. Saturdays and Sundays had to calculate what date of the month this occurred? When does the note come due, and so on. And so some of these things, now you could do the what ifs.

I worked on putting the clock in on the HP-45. I led a team that did the static RAM, that did the CMOS RAM, the CMOS development. I did the HP-65 card reader. Because I wanted to do a bipolar chip. So I designed the motor chip and amplifier read chip for the HP-65. Bob Taggert did the mechanics.

Then I did some work on some of the financial, the HP-80 which Bill Hewlett got Bill Crowley to champion. Hewlett felt the HP-35 got a cold shoulder from the Wall-street community so he wanted to do something they could understand, like future value of money.

Hewlett, even when we were in pretty much full production, he was still a little bit funny, a little bit stingy. He used to go downstairs to the cafeteria and I sat down with a tray across from him, I said, "Hey, we got an RFQ from GE for 10,000 calculators." He says, "Oh, there must be some mistake." I said, "No, "Suppose they want to buy a calculator for every one of their engineers?" Hewlett said, "They can buy fewer of them and let them share."

The HP-35 changed the world. I saw that first hand. I used to go down to University of New Mexico and New Mexico State for college recruiting. I would give a little talk about the HP-35 design challenges. These students were so enthusiastic. But the professors would say, "You know, you've really screwed me up because now what do I do? Do I let them use a calculator? They all can't afford it. Do I have to buy them for everybody?"